In the bustling environment of a commercial kitchen, every second counts. When refrigeration equipment breaks down, the pressure is on to restore functionality without slowing down the line or compromising food safety. Servicing commercial refrigeration units in such settings requires a blend of technical expertise, strategic planning, and clear communication. Here are five proven tips and best practices based on my experience that can help minimize disruption during service calls in commercial kitchens.

1) Flexibility and Communication are Key

When urgent repairs are needed during busy service times, try to schedule service around customer needs. If it doesn’t make sense to work on something at a certain time with kitchen workflow, talk with your dispatcher to rearrange calls to times that better suit the customer. If there really is no other choice, talk with the customer and let them know you will be in their way. Bring only the necessary tools to the workspace and try to stay out of the way. A kitchen is a small space with tight working conditions, so adjust as needed and get it done.

2) Move Equipment Out of the Way

Every repair is different. With some equipment, everything comes out the front — others, not so much. If the unit is easily moved, you can often pull it to the back of the site or even outside to repair it. Most times, though, that is not practical. Often, custom lines are made, and coolers are built into them, or the equipment won’t fit down the line without moving all kinds of other pieces out of the way. The biggest factor is whether you will be interfering in your customer’s space in any way. If yes, do your best to get the equipment out and into a different area.

3) Take Advantage of Digital Controls

Digital controls have come a long way, and they help you know what is going on inside via probe read-outs or status of components. If it says the evaporator fan is running, but visually it is not, you have an idea of where to go. You can get real-time read-out of probes as well. Now, they are not always accurate, but it does give you some information to go off of initially. Some units have full displays like True® ice makers. They actually show temperatures, pressures, status, and everything else on a screen at one time. This is super helpful when diagnosing issues.

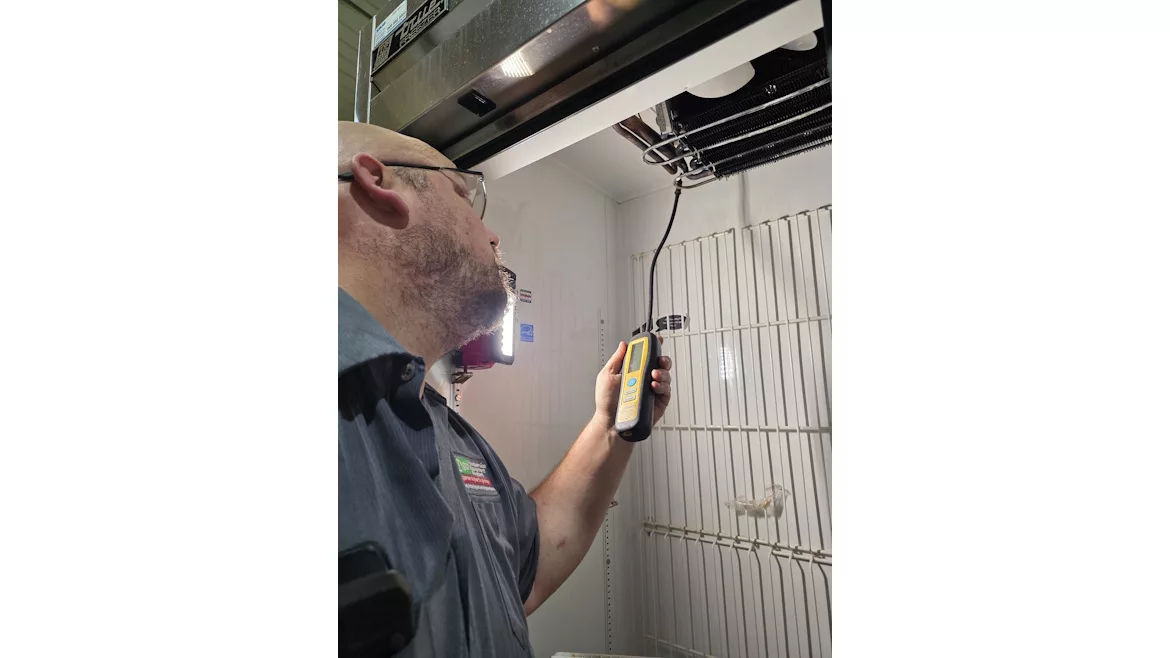

4) Bring the Right Tools

A well-equipped technician is a fast and effective technician. Tools are ever-changing, it seems, but be sure to buy the best you can afford. Basic hand tools are the backbone of any service tech. You also want to have a good quality electrical meter — this isn’t negotiable, it is for your safety and troubleshooting.

Refrigeration tools have made huge strides recently, and everything is wireless probes now. This is important as more equipment is critically charged (precise amount of refrigerant in the system), and hoses can hold gas in them. Also, more and more places are doing burn permits for torch work. If you have a press tool (RIDGID® RP 251 and RLS® Jaws are a perfect match), you can save a ton of time and money. No, it will not completely do away with brazing, but it is another valuable tool to have. I have had situations where I wasn’t even allowed to use a torch inside the facility, but I was able to use a press tool to replace a condensing unit. I saved four extra hours of fire watch and got the job done in way less time.

5) Encourage Preventive Maintenance

Lack of preventive maintenance is probably the biggest offender in slowing down the line, and one of the biggest things we can encourage to minimize having to slow down the line for repairs. I get it, preventive maintenance costs money to the customer, and it is hard to justify when that unit is running. But what about when it is not running? A restaurant’s cook is running to the walk-in every time they need something, or they are packing things into tubs of ice. That is a hassle and a mess. It slows down their efficiency and delays their customers’ food. If we can catch a simple issue during preventive maintenance, we can prevent it from becoming a major issue on a busy Friday night. All points to share with customers who may be on the fence about scheduling maintenance.

Servicing commercial refrigeration equipment in a fast-paced kitchen doesn’t have to mean slowing down the line. With proactive maintenance, strategic scheduling, and the right tools, technicians can keep kitchens running smoothly and minimize disruption. By embracing new technologies and maintaining open communication, both kitchen staff and service professionals can ensure that repairs are handled efficiently, keeping food fresh and customers happy.

Looking for quick answers on air conditioning, heating and refrigeration topics?

Try Ask ACHR NEWS, our new smart AI search tool.

Ask ACHR NEWS

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link