In some respects, servicing right now’s refrigeration methods is not any extra difficult than it ever has been. What has modified, nevertheless, is the necessity to perceive the variations within the newer refrigerant blends. Lots of the generally used refrigerants have been single part, together with R-12, R-22, and R-134a — whether or not a vapor or liquid, the chemical continues to be the identical.

All these refrigerants have been or will probably be phased out. Whereas there are nonetheless models utilizing a few of these refrigerants, it’s merely a matter of time earlier than they are going to have to be repaired or changed. That’s the reason service technicians want to know how one can work with the choice blends with the intention to retrofit current tools, or substitute tools that has failed.

Variations

The necessity for brand new refrigerants to interchange the only part refrigerants, whereas mimicking their efficiency and pressure-temperature relationships, has led to the event of blended refrigerants. Whereas these blends might appear to be they work the identical, there are variations that require different strategies of charging in comparison with a single-component refrigerant.

There are two sorts of blended refrigerants: azeotropic and zeotropic blends. Azeotropic blends are fabricated from two parts and are given a quantity within the 500 Collection of refrigerants. These can often be handled the identical as a single-component refrigerant. Zeotropic blends are comprised of a number of parts and would not have frequent boiling factors for the varied parts. Understanding these traits can save service technicians plenty of bother when coping with blended refrigerants.

Zeotropic refrigerants are topic to temperature glide throughout the varied boiling factors of the completely different chemical parts. The pressure-temperature chart might have a bubble level and a dew level, and the temperature glide is the distinction between the 2. Bubble level is when the primary bubble of vapor types and the refrigerant turns into saturated liquid. Dew level is when the primary drop of liquid condenses from vapor and the refrigerant turns into saturated vapor. If the bubble level (saturated liquid) is used as an alternative of the dew level (saturated vapor) when calculating superheat, it is going to end in an incorrect worth.

Recharging a system after a refrigerant leak can typically result in the necessity to not simply prime off a system, however to fully substitute the refrigerant cost. Because the varied parts of the refrigerant have completely different boiling factors, a leak in a system can lead to shedding extra of certainly one of these parts than the others, throwing the mix out of the designed ratios.

A very good apply to observe is that if greater than half of the cost is misplaced, then recuperate it and substitute it with all-new refrigerant.

Recovering and Charging

When recovering refrigerants, first decide if the refrigerant will probably be reused; for instance, if a restore is carried out and no cost was misplaced. As all the time, use a clear and evacuated restoration tank, and don’t combine the refrigerant to be reused with another refrigerant — even of the identical sort.

After the restore, substitute the liquid line drier and vacuum the system, then return the refrigerant to the system. If the cost is discovered to be low, it might be advisable to make use of new refrigerant. Once more, by no means combine distinct sorts of refrigerants in a restoration tank.

When charging after a restore or part substitute, the system needs to be correctly leak-tested and vacuumed. In a water-cooled system, make certain water is flowing by means of the warmth exchanger. The refrigerant drum ought to have arrows indicating the other way up for liquid and upright for vapor. Introduce sufficient vapor to carry the stress above the freezing level. Whether it is an air-cooled system, liquid could also be launched. When charging in liquid, introduce the liquid on the excessive aspect, ideally on the receiver service valve earlier than the system is began.

If the quantity of cost is understood, it needs to be weighed in utilizing an correct scale. If it is a conversion to a mix from a single-component refrigerant, keep in mind that the amount of refrigerant might have to be adjusted. Begin by utilizing about 80% of the amount of the refrigerant that was changed. As soon as there may be adequate refrigerant within the system, the compressor might be began. Bear in mind to permit the suction stress to come back up into optimistic stress earlier than beginning the system. As soon as the system is operating, if further cost is required, it have to be charged on the suction aspect.

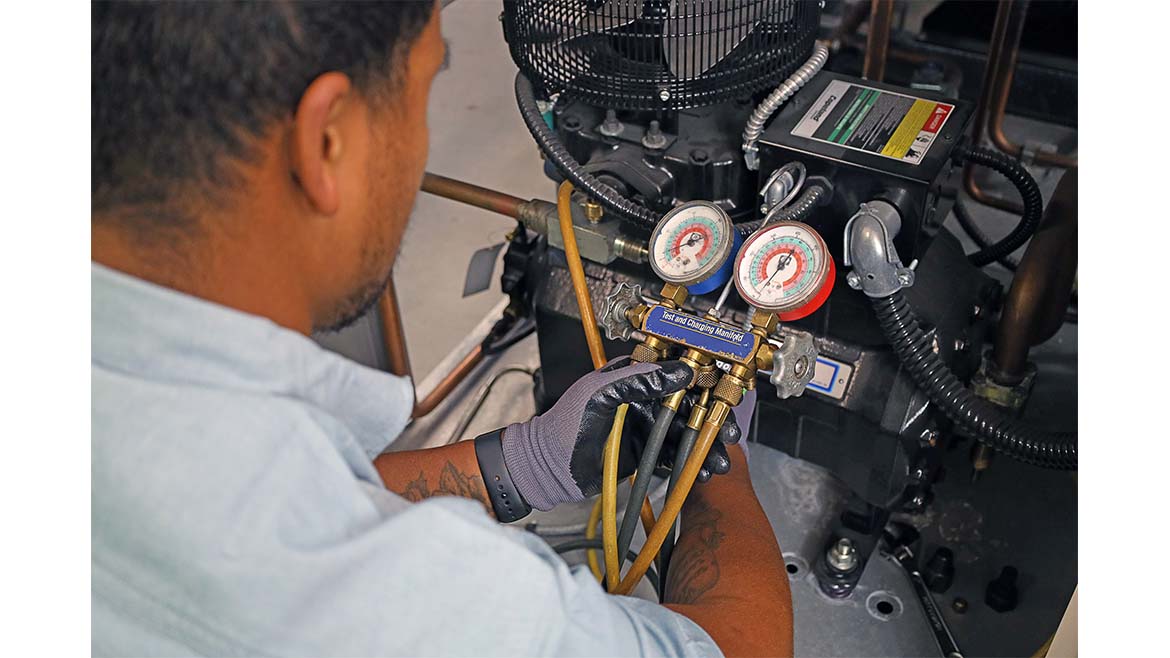

The hazard of introducing liquid on the suction aspect is the danger of liquid slugging of the compressor. Using a flash charger or comparable system to evaporate the liquid whereas charging could also be fascinating. Technicians may be capable of use the manifold to trigger the liquid to evaporate by simply cracking the manifold valve barely and including refrigerant briefly intervals.

The purpose is to maintain a stable column of liquid within the liquid line to the TXV or metering system. Give the system time to stabilize and the field temperature to start to come back down. If the unit has a sight glass and receiver, add simply sufficient refrigerant for the sight glass to simply clear. As soon as the field has come right down to the specified temperature, confirm the working pressures are inside regular vary for the ambient temperature.

Preserve Ratios

The important thing to utilizing any blended refrigerant is to take care of the right ratio of the completely different parts of the refrigerant and perceive how charging in liquid is important to sustaining this steadiness, in addition to defending the compressor from harm.

Understanding how leaks in varied elements of the system can have an effect on these ratios and realizing what temperature glide is and the way it impacts superheat measurement will make servicing and utilizing blended refrigerants a lot simpler.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Supply hyperlink

Add Comment