Refrigeration systems with an air-cooled condenser and receiver located outdoors may need to have additional components installed to prevent the low-pressure switch from opening during startup in extremely low outdoor temperatures.

When the outdoor temperatures are extremely low, the refrigerant pressure in the condenser and receiver may be so low that there is insufficient pressure available to properly feed the metering device. This could cause the system’s low-side pressure to drop rapidly on startup and shut off the compressor on its low-pressure switch. The compressor will continue to short-cycle until the outdoor temperature rises sufficiently to increase the refrigerant pressure in the condenser/receiver.

This continuous short cycling will not allow the system to maintain the proper case temperature and could lead to a tripped oil pressure control, if installed. Adjusting the low-pressure control’s cut-out to solve this problem is not the correct solution. If this is done, then the low-pressure cut-out setting may be so low that it does not adequately protect the compressor.

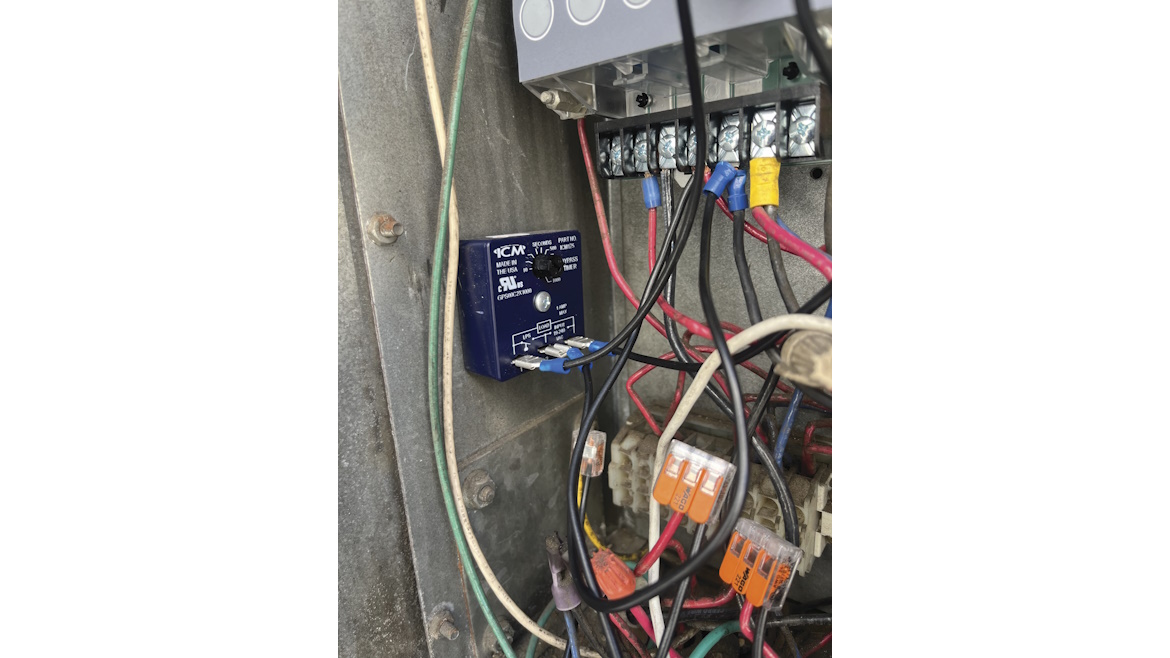

One common solution for this problem is to use a time delay to bypass the low-pressure switch on startup. This will provide sufficient time for the high-side pressure controls to increase the head pressure and the low-side pressure to rise to an acceptable level. Typically, the timer is set to bypass the low-pressure switch for one to two minutes. The bypass timer can be added to a system, if needed, or may be pre-installed by the manufacturer. You might also find it as a programmable setting on some electronic controllers. When adding a bypass timer to a control circuit, make sure the bypass affects only the low-pressure switch and none of the other safety switches.

Another possible solution to this issue is to pressurize the receiver during startup by diverting some of the compressor’s discharge gas directly to the receiver on startup. This will cause the receiver pressure to quickly rise to a preset level during startup and prevent the low-side pressure from rapidly dropping on startup, thus preventing the low pressure from opening on startup.

Another solution is to insulate the receiver and add a heater to warm the refrigerant during the off cycle. This will prevent the receiver’s refrigerant temperature from dropping too low. Also, a check valve will need to be installed between the condenser and the receiver to prevent backflow to the condenser. The liquid line will also need to be insulated from the outlet of the receiver to the inlet of the expansion valve to prevent a drop in its temperature as it flows to the metering device. A suction accumulator is also recommended to protect the compressor from liquid slugging, especially at startup when the refrigerant in the liquid line is at or near ambient temperature.

The necessity of these additional components will, of course, depend on how low the temperature the condenser and receiver can be exposed to during the winter months. Consulting with the system manufacturer can help determine if these additional components will be needed.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link