The time period “warmth exchangers” means little to many individuals until you might be within the enterprise of HVAC, course of heating or cooling, or different industrial purposes. Nevertheless, no matter your degree of understanding of warmth exchangers, one factor is all the time true.

Sustaining the working temperatures of workplace environments or industrial fluids is significant to consolation and manufacturing alike.

Many companies require particular environmental situations for the work they do, others want to keep up fluid temperatures for process-based manufacturing and manufacturing. That is the place warmth exchangers are available in and their capability to chill or warmth rooms or processing methods as required to keep up environmental situations and operational efficiencies.

Warmth switch gear can carry out a number of important capabilities in each heating and cooling. Typically, these methods can seize warmth and direct it elsewhere, wish to outdoors air to get rid of it, or to different purposes the place it’s wanted to extend effectivity and get monetary savings. Different warmth exchangers preserve equipment or chemical substances utilized in processing inside protected working temperatures.

It’s important for constructing operations, plant, and services managers to grasp the several types of warmth exchangers out there for his or her wants to assist them choose the correct system for his or her utility. Understanding easy methods to correctly keep it to make sure most lifespan and effectivity is equally essential.

What’s a Warmth Exchanger?

Warmth exchangers switch thermal power from one medium to a different (liquid, vapor, or gasoline).

Two essential forms of warmth exchangers exist:

- Direct warmth exchangers: Each mediums are available in direct contact with one another in these methods. For instance, a cooling tower cools water through direct contact with air.

- Oblique warmth exchangers: These methods warmth and funky by divided media.

One of the vital widespread situations in services and processing operations is conditions that require heating or cooling. Warmth exchangers are generally utilized in refrigeration, air-con, energy vegetation, chemical processing methods, manufacturing, waste warmth restoration items, and meals processing purposes.

How do Warmth Exchangers Work?

Warmth exchangers depend on the equalization precept to switch warmth between mediums and fluids. Warmth switch happens when:

- Warmth transfers from a scorching to a chilly medium.

- A temperature distinction exists between mediums.

- Warmth misplaced from the new medium equals warmth gained by the chilly medium.

What Varieties of Warmth Exchangers Exist?

Many applied sciences can take away warmth from supplies. Nevertheless, when referring to “Warmth Exchangers,” most individuals equate them to one in all two classes.

- Shell-and-tube warmth exchangers or;

- Plate-and-frame type warmth exchangers.

What’s the Distinction Between a Shell and Tube Warmth Exchanger, and a Plate and Body Warmth Exchanger?

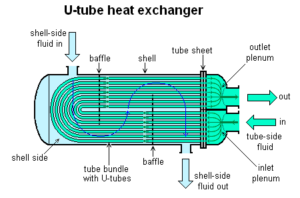

Instance of Fluid Circulation in a Shell and Tube Warmth Exchanger

A shell-and-tube warmth exchanger permits two working fluids to change warmth through thermal contact between tubes housed inside a cylindrical shell. The fluid temperatures contained in the shell and tube differ; this temperature distinction drives temperature change.

Some easy examples of shell and tube warmth exchangers embody boilers, which warmth water through tubes that comprise combusted supplies. One other features a chiller that makes use of chilled refrigerant to switch warmth from the water to relax it to be used in HVAC or course of cooling purposes.

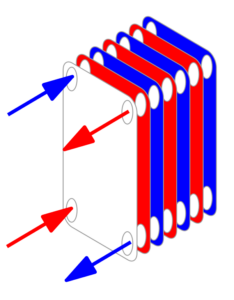

However, a plate-and-frame warmth exchanger makes use of a collection of corrugated plates assembled between a body and strain plates to retain strain and switch warmth. Sizzling fluid flows in a single path by alternating chambers, whereas chilly fluid flows by different alternating chambers. Warmth switch happens as the cold and warm fluids transfer by these chambers.

Although each sorts are available, we’ll heart our dialogue on plate-and-frame warmth exchangers, as they’re among the many commonest warmth exchangers in use at the moment.

Instance of Fluid Circulation in a Plate and Body Warmth Exchanger

Plate-and-frame warmth exchangers carry out liquid-to-liquid change at low to medium pressures. An alternative choice is a gasket-free plate-and-frame warmth exchanger, which operates safely at excessive temperatures and pressures.

Plate-and-frame warmth exchangers accomplish warmth change and resist fouling by a design that includes corrugated plates on a body. Fluids journey throughout the warmth exchanger as scorching fluid flows down one plate and chilly fluid flows up the opposite plate.

What are the Benefits of Plate Warmth Exchangers?

Plate warmth exchangers supply key benefits.

- Exact warmth switch. Customers can add or compress warmth plates to accommodate a particular heating and cooling state of affairs.

- Low capital prices. Plate warmth exchangers are cheap so as to add and set up and have restricted upkeep, cleansing, and working prices.

- Excessive reliability. Plate warmth exchangers expertise much less fouling, stress, put on, and corrosion.

- These methods devour the least power and produce probably the most important impact.

- Simple to increase. Adjustable plates on present frames make it simple to increase capability.

Gasketed plate warmth exchangers differ barely from conventional plate warmth exchangers. These methods use gaskets to seal plates collectively, which retains hot and cold fluids from mixing and protects in opposition to leaks.

Gasketed plate warmth exchangers additionally could use brazing or laser welding as an alternative choice to conventional gasket seals. This permits technicians to stack plates alternatively to counter present circulate. The design lets two fluids circulate in reverse instructions with out mixing whereas warmth transfers from one medium to the opposite by plates.

Gasketed plate warmth exchangers are simple to scrub, making them significantly helpful in meals and pharmaceutical processing or different areas that require excessive sanitation. It’s an easy course of to take away plates for cleansing, enlargement or alternative.

Subsequent Steps

Warmth exchangers play a vital function in cooling or heating rooms or processing methods as required to keep up environmental situations and operational efficiencies. As soon as facility managers perceive their objective, they will decide one of the best methods to use plated warmth exchangers of their facility or processing operation. A Goodway Gross sales Engineer can assist information you with warmth exchanger choice and, as soon as the methods are in place, provide help to keep the warmth exchangers over their lifespan with Goodway Descaling Techniques and Options.

Step one is to decide on and implement the correct warmth change answer in your wants. Sustaining the warmth exchanger over time is crucial. In any other case, it should lose its warmth change skills and find yourself costing most to function. Half II on this two-part weblog collection will handle easy methods to keep numerous forms of warmth exchangers to maximise their lifespan.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Supply hyperlink

Add Comment