Key Takeaways

- MOS sensors are cross-sensitive to VOCs. Metal-oxide semiconductor leak detectors react to household chemicals like hairspray, paint, and cleaning products, triggering false lockouts with zero refrigerant present.

- Customer education is now part of commissioning. A 60-second conversation about chemical use near indoor units prevents the $300 callback three weeks later.

- Verify before condemning. Use a handheld leak detector to confirm sensor readings before replacing functional equipment.

- Callbacks cost $250-400 each. For shops doing 50-100 monthly installs, sensor-related nuisance trips become a serious profit leak.

Technicians across North America have been reporting elevated nuisance trip rates on new R-454B and R-32 installations during our A2L refrigeration transition.¹ The pattern is consistent enough that it’s showing up in service manager meetings and industry forums. The culprit isn’t refrigerant leaks. It’s chemistry.

Understanding the Sensor Technology

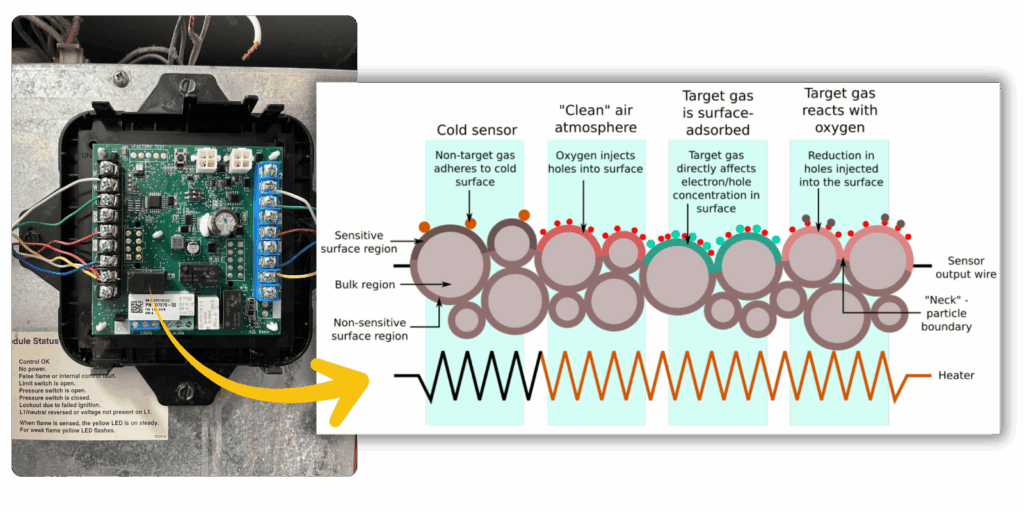

Metal-oxide semiconductor (MOS) sensors used in first-generation A2L leak detection systems don’t just detect refrigerant. They react to reducing gases through oxidation reactions, making them susceptible to cross-sensitivity with volatile organic compounds.²

The mechanism matters for diagnosis: MOS sensors detect changes in resistance across a heated metal oxide surface when exposed to gas. That surface can’t distinguish between R-454B and the VOCs off-gassing from a freshly installed luxury vinyl plank floor.

Common triggers include:

- Hairspray and personal care products

- Fresh paint and wood stain

- Household cleaning products

- Floor adhesives and sealants

- Air fresheners and scented candles

In new construction or recently renovated homes, the concentration of these chemicals can remain elevated for weeks after installation. That’s precisely when most warranty callbacks occur.

The Diagnostic Protocol

Before condemning a sensor, follow this verification sequence:

- Check with a handheld leak detector. If the portable reads zero and the system sensor shows alarm, you’re likely dealing with environmental interference.

- Survey the space for recent chemical use. Ask the homeowner about painting, cleaning, or new flooring.

- Ventilate and retest. Open windows, run exhaust fans for 30 minutes, then verify if the alarm clears.

- Document everything. Photo the sensor reading, note the environmental conditions, and record your handheld detector results.

The sensor may be functional but reacting to interference. Replacing it won’t solve the problem if the chemical source remains.

For technicians still getting up to speed on alternative refrigerants, understanding the A2L safety classification is essential. These refrigerants are mildly flammable, which is why the sensors exist in the first place. The safety requirement isn’t going away. The sensitivity needs to improve.

The Business Impact

Average HVAC callbacks cost contractors $250-400 in rolled labor, fuel, and opportunity cost.³ That’s the visible number. The hidden costs include:

- Technician time pulled from revenue-generating work

- Customer confidence eroded by apparent equipment problems

- Warranty exposure when sensors are replaced unnecessarily

- Reputation risk if nuisance trips happen repeatedly

Multiply callback costs by a shop doing 50-100 installs per month during peak season, and sensor-related callbacks become a serious profit leak. One technician reported 15% of his A2L installs generated nuisance alarm callbacks in the first month.

The Fix Is Operational, Not Technical

The solution isn’t better sensors. It’s better process.

Customer education about chemical use near indoor units is now part of the install handoff. Train your crews to deliver a 60-second briefing that covers:

- What triggers false alarms (cleaning products, hairspray, paint)

- Where to avoid spraying (near the indoor unit air intake)

- What to do if an alarm sounds (ventilate the space before calling for service)

- How long to wait after renovation (let new construction off-gas before installation if possible)

This conversation at commissioning prevents the truck roll three weeks later. Some contractors are including this information on a laminated card left near the thermostat.

Arriving prepared makes customer education easier. Property.com's 'Know Before You Go' tool shows permit history and previous HVAC work before you arrive, so you know whether you're walking into new construction off-gassing or a renovation project with fresh paint. That context shapes the conversation. Understanding proper refrigerant leak checking procedures becomes even more critical with A2L systems. When you do respond to an alarm, systematic verification protects both you and the customer from unnecessary repairs.

What Manufacturers Are Doing

The industry is responding. Second-generation sensors with improved selectivity are in development, though widespread availability is still 6-12 months out. Some manufacturers are updating firmware to add delay timers that reduce nuisance trips from brief VOC exposure.

In the meantime, installation manuals are being updated to include environmental preparation guidelines. Some now recommend:

- Completing painting and flooring work before HVAC installation

- Running ventilation systems for 48-72 hours before commissioning

- Avoiding installation in spaces with active renovation

These recommendations aren’t always practical in the real world of construction schedules and customer expectations. That makes technician awareness even more important.

Looking Ahead

The A2L transition isn’t slowing down. R-454B and R-32 systems will continue replacing R-410A installations across the residential and light commercial market. The sensor technology will improve, but it won’t happen overnight.

Contractors who build education and verification into their standard procedures now will avoid the callback costs that catch competitors off guard. The learning curve is real, but it’s manageable with the right approach.

Sources

- Air Conditioning Contractors of America (ACCA). “A2L Implementation Challenges: Early Adoption Field Reports.” Technical Bulletin. 2024.

- ASHRAE Standard 15-2022. “Safety Standard for Refrigeration Systems.” American Society of Heating, Refrigerating and Air-Conditioning Engineers. 2022.

- ACCA. “The True Cost of Callbacks and How to Stop the Bleeding.” 2024.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link