Key Takeaways

- Replace your leak detector first: Heated diode and corona tip detectors are ignition sources, A2L-specific detectors with PPM readout are non-negotiable

- Check your recovery machine motor type: AC induction motors spark at start/stop; DC brushless motors are A2L-safe

- Buy a left-hand thread adapter now: A2L tanks use reverse threads, look for the double-ring knurl to identify them

- Digital manifolds need firmware, not replacement: Update your PT charts for R-454B’s 1.5-2°F temperature glide

- VOC interference causes false lockouts: Household cleaners, fresh paint, and hairspray trigger A2L sensors, know the troubleshooting path before your first callback

A2L equipment already hit 91% of distributor market share by September 2025, according to HARDI data.¹ If you’ve been waiting to “see how this A2L thing plays out”, it played out.

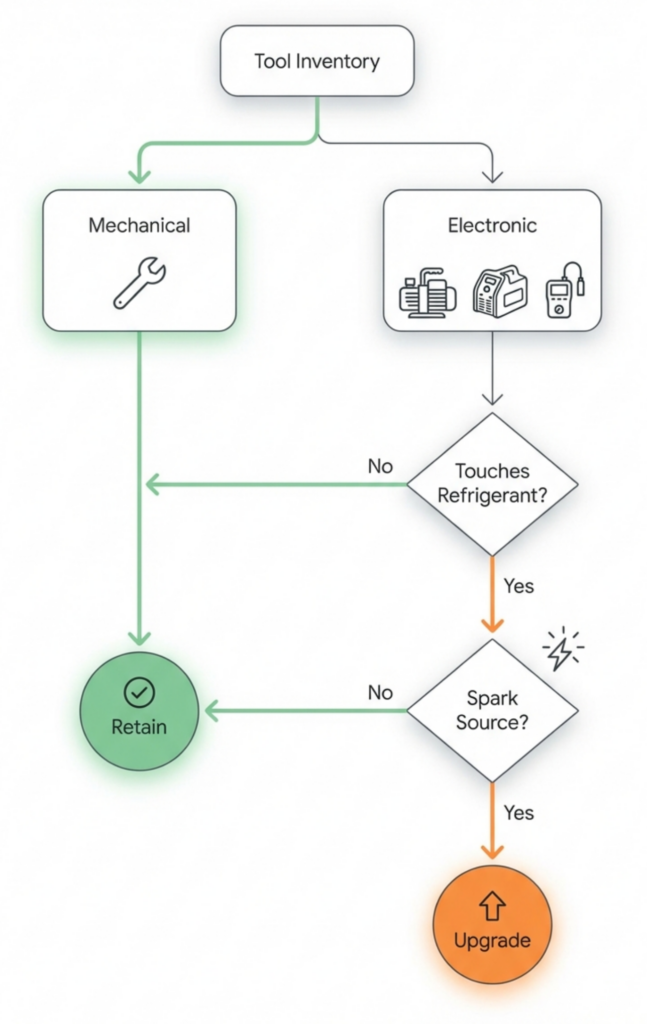

Some techs believe they either need to replace everything in their truck (expensive myth) or nothing at all (dangerous myth). The reality sits somewhere in between. Getting it wrong means wasting money on unnecessary upgrades or, worse, creating an ignition source near mildly flammable refrigerant.

The “Must Replace” List

Leak Detectors

Your old heated diode or corona discharge detector has to go. Those sensor tips reach 600°F or higher, well above the autoignition temperature for A2L refrigerants.² That’s an ignition source, and there’s no workaround.

What you need is an A2L-rated detector with parts-per-million (PPM) readout, not just an alarm threshold. The PPM display matters for two reasons: it helps you find small leaks before they become big problems, and it tells you if you’re approaching dangerous concentration levels in enclosed spaces.

Here’s a field tip worth remembering: standard “sniffer” detectors struggle outdoors or in drafty areas because A2L gases disperse quickly. For those conditions, ultrasonic leak detectors like the Accutrak are your secret weapon.³ Wind doesn’t affect sound the way it scatters refrigerant molecules. Gary picked up an Inficon Whisper for exactly this reason, when your electronic sniffer can’t find what you know is there, listening for the hiss works.

Before heading out on any leak call, make sure you’re solid on proper leak detection procedures, finding the leak is only half the job.

Recovery Machines

Not all recovery machines need replacement, but you need to verify what motor type yours has. AC induction motors spark at start and stop, that’s a problem with flammable refrigerants flowing through the unit. DC brushless motors don’t spark, making them A2L-safe.⁴

Check your machine’s specifications. Marketing language like “A2L compatible” doesn’t always tell the whole story. What matters is the motor type and whether the electrical components are properly sealed. Units like the NAVAC NR7 were specifically designed with DC brushless motors and insulated terminals for A2L work.

Once you’ve recovered the refrigerant, you’ll need to follow proper evacuation procedures before recharging, the fundamentals don’t change with A2L, but the stakes are higher.

Vacuum Pump Switches

Old vacuum pumps with standard toggle or rocker switches can arc internally when you flip them on. That arc near refrigerant vapor is the same ignition risk we’re trying to avoid everywhere else.

Newer A2L-compatible pumps address this two ways: sealed brushless motors that eliminate internal sparking, or switches physically isolated from the work zone.⁴ Kevin Gill explained it well in a recent training, if you’re plugging into a convenience outlet on a rooftop, power down before connecting, then switch on. No spark at the plug means one less ignition opportunity.

If your pump is less than five years old, check the manufacturer’s specs. Many are already compliant. If you’re running a trusty old workhorse from the R-22 days, it’s probably time for an upgrade.

The “Software Update” List

Digital Manifolds

Good news here: your digital manifold hardware is probably fine. The seals are compatible with POE oil, which is used in both R-410A and A2L systems. What needs updating is the firmware, specifically the pressure-temperature charts.⁵

R-454B has a temperature glide of approximately 1.5-2°F, meaning the saturation temperature at the dew point differs from the bubble point. R-32 doesn’t have this glide. Your digital manifold calculates this automatically once updated, but if you’re running outdated firmware, your superheat and subcooling readings will be off.

Check your manufacturer’s website for the latest update. Most major brands released A2L-compatible firmware in 2024.

Analog Manifolds

If you’re still running analog gauges (plenty of techs still are), you’ve got two options: buy new scale plates calibrated for R-454B and R-32, or finally make the switch to digital. The old R-410A scales won’t read correctly for the new refrigerants, and doing the PT math in your head on every call gets old fast.

Vacuum Gauges

Your micron gauge is 100% compatible. A micron is a micron regardless of what refrigerant you’re evacuating. No changes needed here.

Hoses

This one’s more nuanced than the “replace everything” crowd suggests. The real contamination risk is POE oil cross-contamination, not the hose material itself.⁵ Best practice is dedicated A2L hoses, separate colors help you keep them straight. But if you’re flushing your hoses properly between refrigerant types, you’re technically compliant.

One note: R-32 operates at slightly higher discharge temperatures than R-410A. Make sure your hose gaskets are fresh and in good condition to handle the additional thermal stress.

The “New Purchase” List

Left-Hand Thread Tank Adapter

This is your first purchase if you haven’t made it already. A2L refrigerant tanks use left-hand (reverse) threads on the 1/4″ SAE flare connection.⁶ Your existing yellow jacket hose won’t thread onto an R-454B or R-32 tank without an adapter.

The visual identifier is a double-ring cut into the tightening knurl, that’s the universal symbol for left-hand threads across the industry. You can either buy an adapter like the NAVAC F2010 that connects your existing hose to the new tanks, or invest in a dedicated charging hose with the left-hand fitting already installed.

Don’t show up to your first A2L job without one. Nothing kills momentum like driving back to the supply house because you can’t connect to the tank.

@hvacknowitall Lefty tighty, righty loosey… A2L refrigerant tanks will be left hand thread, which is the reverse of the current configuration. @NAVAC F2010 A2L adapter will allow you to use your current charging hose to connect to A2L tanks such as R32. I will cover the entire hose assembly on the next one. #hvac #hvacr #refrigerant #a2lrefrigerant #hvacsystem #hvaclife #hvacknowledge #refrigerationeducation #hvactools #hvactraining #mildlyflammablerefrigerant #commercialHVACservice #residentialhvacservice #hvacservice #hvacjourneyman #hvacapprentice ♬ original sound – HVAC Know It All

Analog Manifold Scale Plates

Old R-410A scales won’t read R-454B PT correctly. Investment required if not switching to digital.

Before you head to that first A2L install, Property.com’s “Know Before You Go” tool shows you permit history and equipment records. No surprises when you pull up and find they’ve already swapped to R-454B, or when the homeowner claims the system is “only a few years old” but permit records tell a different story. Top techs use Property.com to arrive prepared and build trust from the first interaction.

The Callback Killer: VOC Sensor Interference

A2L sensors use MOS (Metal Oxide Semiconductor) technology that detects hydrocarbons, including volatile organic compounds from common household products.⁷ When a system locks out on “Leak Detected” but your handheld sniffer finds nothing, the culprit is often fresh paint, glass cleaner, silicone caulk, or even hairspray triggering a false alarm.

Your first troubleshooting question: “Did anyone paint, clean, or use aerosol products in this room recently?”

We recently wrote a full breakdown on this issue: A2L Sensor False Alarms: Why VOCs Trigger Nuisance Lockouts on R-454B Systems.

Quick-Reference Tool Compatibility Chart

| Tool Category | Action Required | Why |

|---|---|---|

| Leak Detector | REPLACE | Heated tips are ignition sources (600°F+) |

| Recovery Machine | CHECK MOTOR | DC brushless = safe; AC induction = sparks |

| Vacuum Pump | CHECK SWITCH | Old toggles can arc internally |

| Digital Manifold | UPDATE FIRMWARE | Needs R-454B/R-32 PT charts for glide |

| Analog Manifold | RESCALE | Old R-410A scales read incorrectly |

| Tank Adapter | BUY NEW | Left-hand threads on all A2L tanks |

| Hoses | OPTIONAL | Dedicated hoses = best practice |

| Vacuum Gauge | NO CHANGE | A micron is a micron |

Now You Know

You don’t need to replace everything in your truck. A few strategic purchases, a proper leak detector, an LH thread adapter, and possibly a recovery machine upgrade, plus some firmware updates will get you compliant.

R-454B and R-32 systems are hitting jobsites across the country right now. The techs who prepared six months ago are running smooth installs. The ones who waited are scrambling.

Start with the must-replace items. Update your manifold firmware. Grab an adapter. Then get after it.

Additional Sources

- “A2L Equipment Reaches 90% of Market Share as Cooling Season Ends,” HARDI, 2025

- “Technology Transitions Program,” U.S. Environmental Protection Agency, 2025

- “Tools for Flammable A2L Refrigerants,” Ty Branaman (Love2HVAC), YouTube, 2025

- “Flammable A2L Refrigerants Explained for Technicians,” Kevin Gill, HVAC Know It All Podcast, 2024

- “R-454B vs R-410A Side by Side,” HVAC School, 2024

- “A2L Adaptor for LH A2L Refrigerant Tanks,” NAVAC Global, 2024

- “VOC Sensors Laboratory Testing Protocol,” South Coast Air Quality Management District (AQMD), 2023

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link