Enlargement valves are used to inject refrigerant into the evaporator of refrigeration and AC/HP programs at a situation that may permit the refrigerant to soak up warmth. They’re sized in order that the quantity of refrigerant they inject will intently match the calculated load on the system evaporator at a regular set of circumstances. There are a lot of differing types starting from easy orifices and guide hand valves to extremely adaptive digital growth valves. Nonetheless, there are solely 2 totally different courses of growth valves: mounted and adaptive.

Mounted Enlargement Valves

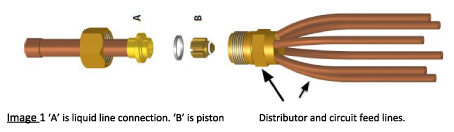

Mounted orifice growth valves are easy gadgets that can’t change the quantity of refrigerant injected into the evaporator to satisfy adjustments within the evaporator warmth load. This isn’t to say that the quantity of refrigerant they inject by no means adjustments, it’s the quantity injected doesn’t change purposefully to match a brand new warmth load. The commonest kind of mounted orifice gadgets are piston and capillary tubes. Pistons are basically a gap in a chunk of metallic held in a distributor that’s connected to the inlet of an evaporator. Picture 1 exhibits a piston (B) and the distributor to the fitting of it. The scale of the opening and the stress distinction throughout it determines the quantity of circulation by means of it.

You’ll discover that I added the qualifier “at a regular set of circumstances” within the first paragraph when describing how metering gadgets are sized. That is very true for piston kind gadgets because the circulation by means of one is decided by the stress distinction throughout it which is the distinction between the evaporator and condensing pressures. If you will measurement/choose one for a system, it is advisable to use a set of circumstances that the system will function in and it must be a set of values that everybody agrees upon and subsequently is standardized throughout that software. These values are the evaporator and condensing stress and embrace values for superheat and subcooling. An instance of a standardized air con set of values can be ARI A/C CT 130F which specifies a 45F evaporator temperature, 130F condensing temperature, 20F helpful superheat and 15F subcooling. Utilizing standardized circumstances permits the business to match up parts primarily based on capability in order that they’ll work with one another within the system.

If the distinction between the condensing and evaporator pressures decide circulation by means of a piston orifice, then when these values change, so will the circulation. Subsequently, you will note decrease values of evaporator superheat (And subcooling for that matter.) when the skin temperature is excessive. In case you take a look at a charging chart for a piston outfitted air con system, you’ll discover that for a given worth of indoor Wb temperature, the superheat goal worth will enhance when the out of doors temperature decreases and vice versa. On a scorching day with low humidity, evaporator superheat may be within the single digits. A unclean condenser or poor airflow on the identical day can lead to a flooded compressor. Conversely, on a cooler day with rain falling, superheat is excessive sufficient to lead to poor dehumidification

Capillary tubes are lengthy slim diameter tubing and have some capability for adapting to adjustments in condenser stress. That is as a result of quantity of subcooling reducing as condensing stress will increase in programs which have a important cost. When subcooling is diminished, the stress drop that happens within the cap tube will consequence within the liquid flashing to a vapor sooner and since vapor takes up extra quantity than liquid, this reduces the quantity of refrigerant that may circulation by means of the cap tube. Nonetheless, cap tubes nonetheless work greatest when excessive and low facet pressures are regular. Cap tubes are sized by figuring out the load on the desired circumstances after which selecting a cap tube of the advisable diameter and slicing it to the advisable size. In case you mess this up, count on both an excessive amount of or too little circulation into the evaporator and an sad system.

Take heed to Jamie Kitchen and Gary McCreadie focus on superheat because it pertains to adaptive vs. mounted metering gadgets and subscribe to the HVAC Know It All Podcast.

Adaptive Enlargement Valves

The opposite important class of growth valves is the adaptive kind. Adaptive signifies that the growth valve will reply to a change in load by altering how a lot refrigerant is injected into the evaporator. The preferred of those is the thermal growth valve or TXV. A TXV makes use of stress developed in a sensing bulb mounted on the evaporator outlet tube in addition to the stress within the evaporator to behave as alerts. In case you take a look at Picture 2 you will note how these alerts are utilized throughout a diaphragm positioned within the energy factor of the TXV. On this case the pressures act as a power making an attempt to open and shut the valve and oppose one another. On the underside of the diaphragm the evaporator stress is utilized together with a second power equipped by a spring. This spring is the superheat spring. On prime of the diaphragm the stress from the sensing bulb is utilized. The sensing bulb is the opening power whereas the evaporator stress and superheat spring are the closing forces.

Picture 2

If the load on the evaporator will increase, initially there won’t be sufficient refrigerant within the evaporator to match the upper load. The elevated warmth being absorbed by the refrigerant will consequence within the liquid boiling off sooner and solely vapor left farther up the evaporator circuit. This vapor nonetheless absorbs warmth and can lead to extreme superheat on the evaporator outlet. It will enhance the sensing bulb temperature and stress. This bulb stress is transmitted by means of the cap tube connecting the bulb to the TXV energy head and onto the highest of the diaphragm. Since that is a gap power, it’s going to overcome the evaporator and spring power and drive the valve open. The elevated refrigerant within the evaporator will cut back the superheat of the leaving refrigerant.

While you alter the superheat setting on a TXV, you altering the power utilized by the superheat spring. This power ensures there’s at all times a minimal quantity of superheat current within the evaporator to guard the compressor towards flood again. It is suggested to not alter the tremendous warmth setting till you’ve eradicated all different potential causes of incorrect superheat or it has been suggested by the producer to take action. Adjusting superheat on a TXV when one other difficulty is the issue can flip one thing that will have been a simple restore into one thing extra concerned and costly.

For evaporators which have a number of circuits a distributor is used to feed the totally different circuits. The distributor (See picture 1) introduces a big stress drop between the TXV outlet and the outlet of the evaporator. This stress drop have to be accounted for therefore in some of these functions an exterior equalized TXV is used. These take the stress from the evaporator outlet after all of the stress drops have occurred and apply it to the underside of the TXV diaphragm by means of a tube related from the facet of the TXV to the outlet of the evaporator (See Picture 3). If this was not executed, the temperature equal of the stress drop can be added to the superheat required to open the TXV and it could underfeed the evaporator. For easier evaporators with single circuits and little stress drop an inside equalized TXV can be utilized. These apply the stress straight from the evaporator inlet/TXV outlet below the diaphragm. Whereas you need to use an exterior equalized TXV when it isn’t obligatory, you could by no means use an inside equalized TXV when an exterior one is required.

Picture 3: Crimson Arrow factors to the distributor

The opposite main kind of adaptive growth valve is the digital growth valve or EEV. They include a valve physique and motor or solenoid to drive it open and closed. A controller is used that may be programmed for various refrigerants and superheat values to regulate to. This makes use of a stress and temperature sign to find out the evaporator saturation temperature and the quantity of superheat current and adjusts the opening and shutting of the valve in keeping with the values set within the programming. There may be a whole lot of flexibility in how the valve can management and so they can be utilized throughout a variety of functions from very low temperature freezers as much as consolation cooling. Typically, they’re set to keep up a set superheat worth that’s near optimum on the circumstances that the programs will function below. Different designs will at all times be making an attempt to scale back the superheat as little as doable whereas nonetheless being secure and provide much more vitality saving potentialities (See Picture 4)

Picture 4: Superheat under MSS will lead to unstable feeding. Observe how TXV superheat is greater than obligatory.

EEV’s are available 2 important varieties, stepper motor valves and pulse width modulated. The stepper motor valve will drive the valve open or closed in small incremental steps utilizing a stepper motor that turns one path when a optimistic sign is shipped to it and in the wrong way when a unfavourable sign is utilized. (Picture 5) How briskly the valve opens or closed may be set in addition to minimal and most opening ranges. Pulse width modulated valve are basically sturdy solenoid valves that may both be 100% open or 100% closed. How lengthy the valve stays open over a given period of time vs. closed determines how a lot refrigerant is injected into the evaporator. These valves have the benefit of excellent oil return however have to be put in away from different line parts to keep away from liquid hammer points.

Picture 5: Stepper Motor EEV

To summarize, mounted metering gadgets work properly when circumstances are fixed and evaporator hundreds don’t change a lot. When circumstances can very equivalent to condensing stress or evaporator warmth hundreds, care have to be taken to make sure that the valve will meet the necessities however won’t over feed the evaporator and slug the compressor. Adaptive metering gadgets permit for higher flexibility as they’ll open or shut to satisfy demand no matter altering circumstances if the circumstances fall inside a particular vary. TXV can throttle to half of their rated capability after which open to offer as a lot as 30% above their rated capability when the state of affairs requires it. EEV’s have a good higher throttling vary on the low finish and may management hundreds down to twenty% of their rated capability and even much less.

By Jamie Kitchen

Comply with HVAC Know It All on Instagram, Fb, YouTube and LinkedIn and LISTEN to the HVAC Know It All Podcast

Save 8% on purchases at TruTech Instruments with code knowitall (excluding Fluke and Flir merchandise)

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Supply hyperlink

Add Comment