The AHR Expo is a showcase of innovation and ingenuity, where HVACR manufacturers from around the globe converge to unveil cutting-edge technologies and solutions designed to tackle the industry’s most pressing challenges. This year, exhibitors placed a strong emphasis on energy efficiency and sustainability, highlighting products that not only reduce energy consumption but also align with global decarbonization and electrification goals.

Electrification Continues

Even though the political winds have changed since the last presidential election, most manufacturers remain confident that electrification will continue to be a key trend. Infinitum, for example, expects to see skyrocketing growth in electrification, said Stephen Mathew, director of product management at Infinitum.

“AI and data centers are putting enormous pressure on the HVAC world to prioritize energy management and deliver more efficient cooling systems that optimize power consumption in buildings and support electric grid stability,” said Mathew. “Motors play a key role in a building’s energy consumption, data centers, and other mission-critical facilities. In fact, 40% of a data center’s energy consumption is consumed by motors in HVAC equipment to cool servers. Infinitum’s next-gen, sustainable motor systems support decarbonization initiatives by powering cooling equipment with 20% less energy, 20% fewer emissions, and no waste.”

MOTOR SYSTEM: Infinitum’s Stephen Mathew (left) demonstrates how the company’s Aircore Heavy Duty motor system benefits centrifugal pumps and industrial blowers. (Courtesy of Infinitum)

Heat pumps also play a key role in the electrification movement, but for them to have a meaningful impact on decarbonization and electrification, they need to utilize technologies that make them more competitive in colder climates, as this will increase their adoption across more of the country, said Brian Dail, application engineering manager at Danfoss Climate Solutions.

“Danfoss’ vapor injected scroll compressor, EKE110 controller, and economizer products all make it easier for heat pumps to operate in lower ambient conditions, and they also provide efficiency improvements in these same conditions. These are critical for heat pumps to have a wider adoption across climates,” said Dail.

As new heat pump system technologies continue to support the electrification and decarbonization of space and water heating, Copeland’s integrated compression, drives, and controls solutions are helping to meet energy-efficiency and capacity requirements, said John Schneider, president of HVACR technologies at Americas at Copeland.

“Copeland will soon launch its next-generation, variable-speed scroll compressor platform: a new best-in-class offering designed to deliver excellent performance in the residential heat pump and air conditioning market,” said Schneider. “This solution-based offering combines proven scroll performance with matched inverter drive technology for long life, reliability, and ease of application.”

Advanced Technologies

The advanced technologies needed to support the electrification movement were on display all over the AHR Expo. Danfoss, for example, showed its new line of variable-speed, vapor injection, and scroll compressors, as well as its fixed-speed compressors that have recently been approved for vapor injection.

“To further aid with vapor injection, our new EKE110 controller controls superheat entering a vapor-injected compressor’s vapor injection port,” said Dail. “The EKE110 can also monitor the compressor’s discharge temperature. This will allow it to enter ‘wet injection’ mode if the scroll compressor’s discharge temperature is too high, enabling the scroll compressor to operate with a larger operating envelope and allowing a heat pump to provide higher leaving water/leaving air temperatures at lower outdoor temperatures. The EKE110 is designed to be used with Danfoss scroll compressors but can potentially be used with other manufacturers’ compressors as well.”

INJECTION TECHNOLOGY: The injection technology in the new Danfoss VZH-VI compressor range makes it easier for heat pumps to operate in lower ambient conditions. (Courtesy of Danfoss)

In addition, Danfoss showcased its vapor injection applications, which included electric expansion valves and brazed plate heat exchangers. The braze plate heat exchangers utilize Danfoss’s microplate technology, enabling smaller heat exchangers to deliver the same level of heat transfer, said Dail.

Copeland demonstrated its commitment to sustainability by showcasing products that support the energy transition and accelerate the adoption of low-GWP refrigerant technologies across heating, cooling, refrigeration, and industrial applications, said Schneider. Among these were advanced cooling solutions specifically designed to improve efficiency in energy- and heat-intensive data centers.

“The Copeland oil-free centrifugal compressor with Aero-lift bearing technology unlocks new opportunities for air-cooled data center chillers, delivering best-in-class performance and increased efficiencies in part-load and full-load conditions,” said Schneider. “In addition, the Copeland YDV variable-speed scroll platform is optimized explicitly for data center applications and delivers best-in-class efficiency, reliability, and performance across a wide range of outdoor ambient and evaporating temperatures.”

Copeland also showcased its YAW vapor-injection optimized scroll compressor, which is capable of delivering high supply air temperatures at outdoor temperatures as low as -25°F. This technology enables the creation of reliable, high-efficiency heat pumps that can perform effectively in cold climates, supporting wider adoption across all regions. On the commercial refrigeration side, Copeland highlighted its expanded CO2 solutions and optimized scroll compression platforms for A2L and R-290 refrigerants.

Infinitum unveiled the Aircore Heavy Duty, a next-generation motor system specifically designed for mission-critical HVAC fan and pump applications. According to Mathew, this sustainable motor reduces energy consumption, emissions, noise, and waste, while delivering reliable performance for the most demanding tasks.

“The Aircore Heavy Duty features an integrated variable-frequency drive and sustainably powers demanding, energy-intense applications with up to 25% more efficiency, while being 50% lighter and 60% shorter when compared to conventional motor and drive solutions,” said Mathew. “Built with a rugged exterior for protection against dust, dirt, and water, the Aircore Heavy Duty operates reliably in harsh outdoor or wet environments and at high efficiency over a wide range of operating points.”

Infinitum also showcased new motor system technology that features an integrated Active Front End within the VFD, which reduces total harmonic distortion. This feature improves HVAC equipment efficiency, reliability, and safety, while eliminating the need for bulky, energy-consuming passive filters, said Mathew. By integrating this feature, he added, the technology saves space, energy, and costs, while achieving greater harmonic reduction.

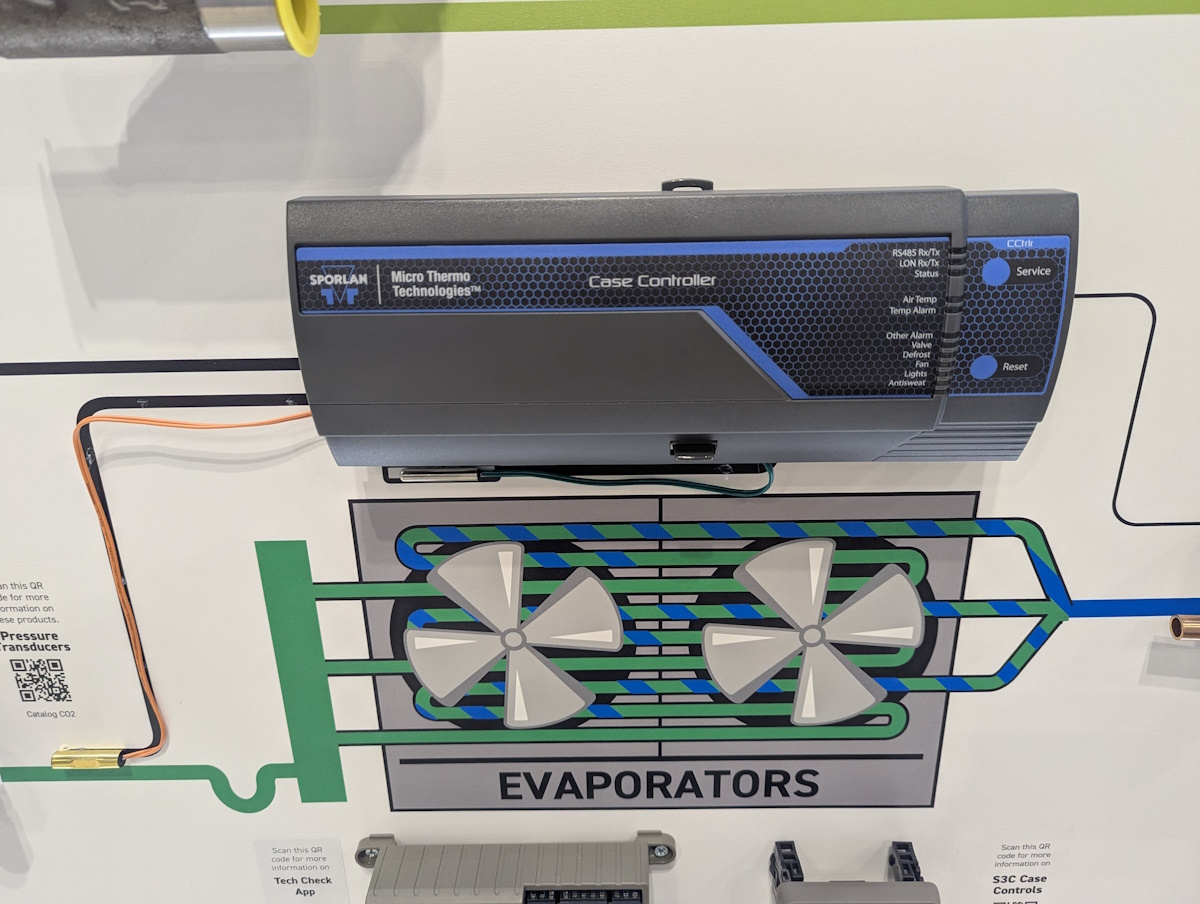

CO2 CONTROLS: Sporlan displayed its Micro Thermo controls for CO2, which are designed to increase the energy efficiency of CO2 refrigeration systems in supermarkets. (Staff photo)

The Sporlan Division of Parker Hannifin strives to be the market leader in energy-efficient and sustainable HVACR solutions that enable a better tomorrow, said John Eric Hoffmann, marketing communications manager at Sporlan. To that end, they introduced several new products, including the multi-purpose gas cooler (GCM) valve.

“The GCM valve is used in transcritical CO2 applications in supermarket refrigeration, so that our customers can move to natural refrigerants for their cooling systems,” said Hoffmann. “In addition, we showcased products for the new lower-GWP A2L refrigerants in both air conditioning and refrigeration systems. Two of these products are our check shut-off valve (CSOV) and safety shut-off valve (SSOV), which are UL certified for A2L refrigerants and used in walk-in cooler applications to provide safety in a customer’s system if a leak emerges.”

Other products Sporlan displayed included Micro Thermo controls for CO2, which are designed with high-performance algorithms to increase the energy efficiency of CO2 refrigeration systems in supermarkets, as well as new TEVs, which have new charges for both commercial and residential air conditioning. “We are pleased to learn that these have been independently tested by several of our prospective and legacy customers, who are indicating that these units exceed the performance of our direct competitors in new A2L systems,” said Hoffmann.

As shown here, the AHR Expo once again demonstrated the HVACR industry’s commitment to innovation, with manufacturers unveiling groundbreaking solutions that prioritize energy efficiency, sustainability, and the transition to lower-GWP refrigerants.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link