✕

The Federal Registrar on March 6, 2024 published the Department of Energy’s (DOE) statement that it “has reviewed ANSI/ASHRAE/IES Standard 90.1-2022 … and determined the updated edition would improve energy efficiency in commercial buildings.” The DOE issued this determination due to DOE’s Energy Plus modeling a 9.8% increase in building operational efficiency compared to the 2019 Standard edition. Several architectural and mechanical design factors contribute to the new projected performance levels, almost doubling the 4.7% efficiency increase compared between the ASHRAE 90.1 2019 and 2016 Standards. ASHRAE’s position document on building decarbonization states in the document’s abstract that “by 2030, the global built environment must at least halve its 2015 GHG (Greenhouse Gas) emissions.” The DOE and ASHRAE are continuing to push toward carbon neutrality by developing building standards to enhance architectural features to reduce building loads.

Mechanically, lower building loads result in lower HVAC airflow rates to meet peak cooling and heating demands. This is good news, reduced airflow at peak demand requires less air handler fan horsepower. However, airflow reduction will require engineers to pay closer attention to another load often less apparent in the presumed “dry” climate of the Sonoran Desert region. During July, August and a good portion of September, the Desert Southwest has an annual monsoon season, when moisture migrates north from the Gulf of Mexico, significantly increasing outdoor humidity levels. Historically, conventional all-air systems have been designed to meet the extreme 115°F or higher summer dry bulb conditions. Air handers were laid out with elevated airflow rates and DX units de-rated to meet a 115°F design day cooling loads. However, the actual peak total load occurs during the Monsoon season when outdoor air dew point levels can exceed 70°F. Older buildings were designed and built with lower R-value wall and roof ratings and inferior glazing resulting in higher heat transfer coefficients. Greater conductive and radiant heat transfer through perimeter walls require higher airflow volumes from HVAC systems of approximately 1.0 cfm/ft². Air handling unit (AHU) cooling coils are often designed with air conditions of 55°F DB/54°F WB to maintain building space conditions of 75°F at 50% RH, resulting in dew point depressions of between 1°F to 2°F degrees. However, to meet recent Standard 90.1 design objectives, Southwestern Desert MEP design strategies will need careful evaluation, especially if supply air and building humidity levels are to be controlled and maintained. Historically, air handlers supplying air at 53.3°F dew point (55°F DB/54° F WB @ 1100 ft elevation) in Phoenix, Arizona were “adequate.” High enough airflow rates can control building humidity at a 1.8°F dew point depression even during monsoon months.

However, since local Arizona building codes are adopting more recent Standard 90.1 editions, building heat transfer coefficients, along with airflow volume rates, are being reduced to meet 115°F design days. A case in point, the City of Scottsdale has recently adopted IECC-2021, which recognizes ASHRAE Standard 90.1-2019 as a viable alternate path. Higher efficiency architectural designs and lighting power reductions are decreasing peak sensible loads, thereby lowering HVAC airflow rates required to meet peak demand. The challenge: will lower airflow rates adequately meet latent loads when air is supplied with lower dew point depressions?

Project Design Requirements:

SmithGroup, a national integrated architectural and engineering design firm committed to promoting innovative and carbon neutral building designs, decided to renovate their existing 23,000 ft² Phoenix office space in 2021 instead of relocating when their lease was set to expire. Staying and renovating their current office provided an opportunity to demonstrate their corporate culture, a culture that celebrates “purpose, people and projects” and an integrated architectural and engineering design process. Building aesthetics, functionality and employee health and well-being were imperative for both upgrading their existing large open office area and redesigning 5,000 ft² of floor space referred to as “client spaces.” (Figure 2)

(Figure 2)

The Sonoran Desert is an extreme environment, due not only to challenging outdoor summer conditions, but other environmental factors as well. The region is currently in drought, extreme drought in some areas, raising local concern for long term water availability. These unique environmental factors were considered and showcased by SmithGroup’s design team by adopting an aesthetic that embraced “the beauty of contrast (white and black office features) and the dichotomy between opposing elements”. (Figure 3)

(Figure 3)

To meet decarbonization objectives, their “open office” mechanical design approach was to reuse existing DX rooftop package units, thereby reducing waste and embodied carbon. For their new “client focused” areas, a more innovative MEP design was chosen that would comply with and exceed the ASHRAE Standard 90.1-2016 requirements. LEED and WELL building accreditations were also pursued to create a healthier work environment and to make a statement regarding SmithGroup’s commitment to sustainability.

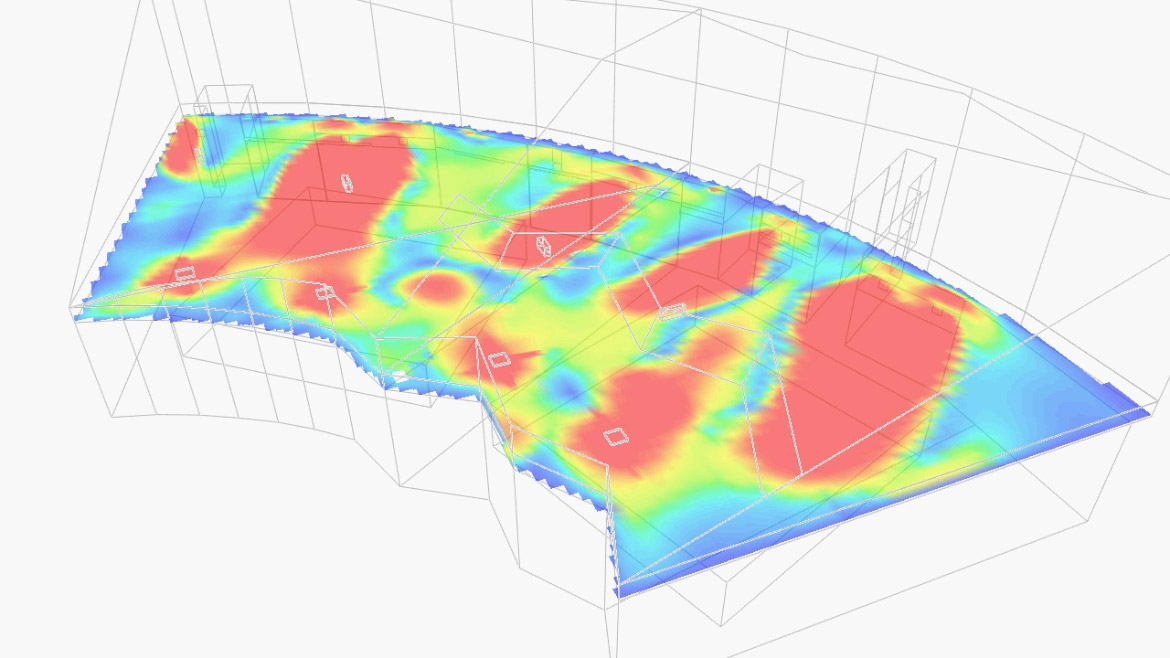

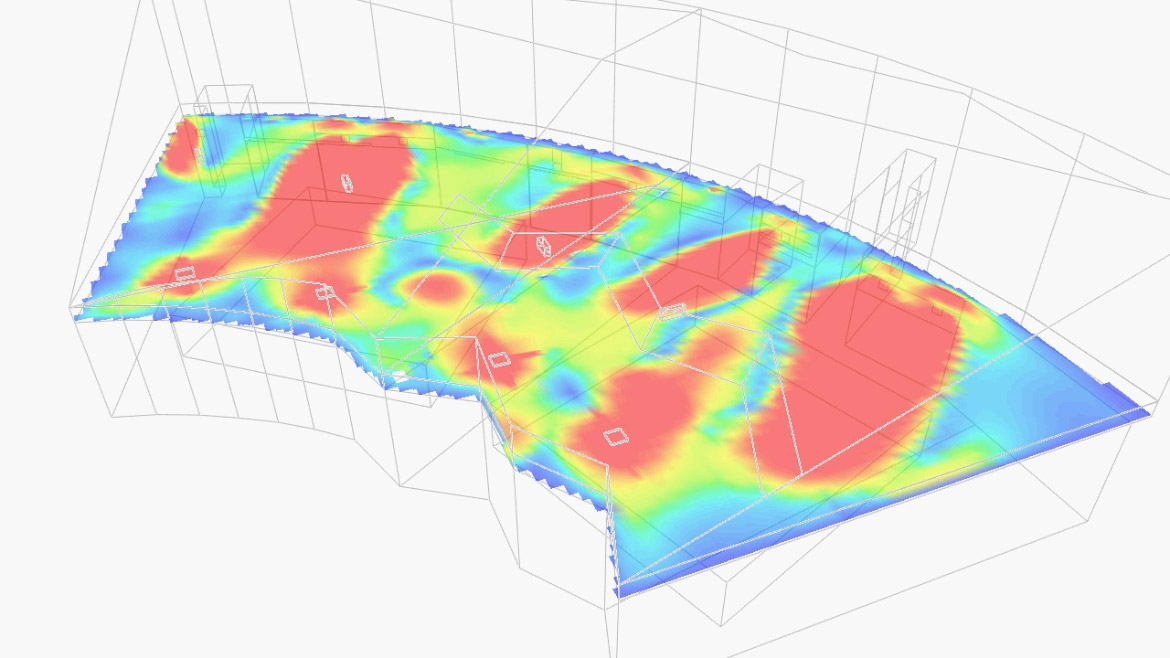

The open office space has exposed sloping ceilings that extend to thirty feet high. Existing DX unit supply air duct, originally concealed within interior zone soffits, was abandoned and removed. The original duct layout injected high velocity air across an open office space to a glazed perimeter wall fifty feet away, resulting in insufficient space mixing and drafts. Non-uniform space temperatures and solar radiant hot spots were present at various locations within the zone. Computational fluid dynamic (CFD) modeling was performed to inform the design team how to best provide a more comfortable environment. (Figure 4 and 5)

(Figure 4: Velocity Profile for Existing Distribution)

(Figure 5: Velocity Profile for Renovated Distribution)

It was determined that new overhead ductwork with supply registers extending up from the vertical plane of the previous soffit area, across a wood ceiling to the perimeter wall, would more effectively distribute air and eliminate non-uniform thermal profiles and drafts. Perimeter solar loads would be more effectively addressed resulting in improved occupant thermal comfort. This newly considered duct design and air distribution profile would result in superior air distribution and space mixing throughout the open office, a key factor in meeting the ASHRAE 55 and LEED thermal requirements. (Figure 6)

(Figure 6)

Added ductwork extensions were coordinated closely with the overall interior design to showcase how architecture and engineering can work together. To meet LEED and WELL building indoor air quality (IAQ) requirements, MERV-13 filtration was added to the existing package DX units. Carbon dioxide (CO2) sensors were installed in all high occupancy spaces to monitor CO2 levels and a demand control ventilation (DCV) sequence was added to the DX unit control sequence.

To demonstrate SmithGroup’s engineering capabilities, a more innovative MEP approach was adopted to serve their new 5,000 ft² client spaces area to reduce operational carbon. A chilled beam system was evaluated, a high-performance HVAC design concept that requires less building square footage than conventional HVAC systems. Thinking beyond a more conventional decoupled hydronic design approach, SmithGroup’s engineers considered Munters technology created over ten years ago when they began production of an innovative DX-Dedicated Outside Air (DOAS) unit using desiccant wheel technology regenerated by compressor heat rejection. Adopting this unique DOAS configuration allows design teams to decouple a DOAS unit from a chilled water central plant while supplying ventilation air at a low enough dew point to control building humidity. A single primary piping loop can be engineered supplying 55°F to 60°F chilled water from central plant chillers to the beams to meet only a building’s sensible load. More conventional chilled beam designs require two chilled water loops; a primary loop supplying approximately 44°F chilled water to DOAS units for outside air dehumidification and building humidity control, and a secondary loop isolated from the primary by a plate and frame heat exchanger to supply chilled water at temperatures of 2°F to 3°F above space dew point to beams located in each zone. Elevating chilled water temperatures significantly reduces chiller lift resulting in greater central plant efficiency, while eliminating the need for a primary/secondary chilled water loop and its associated piping, heat exchanger and pumping costs.

Elevating chilled water temperatures invites another design consideration. Common water-cooled plant designs can readily be replaced with newer more efficient air-cooled chiller technology currently available in our market today. Air-cooled chiller efficiencies with leaving water temperatures at 55°F or more rivals water-cooled plant performance producing 44°F or lower chilled water. Air-cooled central plants offer another advantage by reducing system-first cost and life-cycle costs. Cooling tower water, water treatment, associated piping and tower installation and maintenance costs would be eliminated. Today’s air-cooled chillers can also be configured with redundancy. Should a condensing loop fail, plants can still remain operational without requiring a second chiller.

Designing a 100% dedicated outside air unit for the proposed chilled beam system still had to be closely evaluated. DOAS units not only need to adequately dehumidify outside air, they have to supply air at a low enough dew point to control a building’s latent gain. For decoupled hydronic systems, chilled beams will condense if building space dew points rise above chilled water temperatures. In Phoenix, it is not uncommon to see approximately 44°F chilled water supplied to DOAS cooling coils resulting in a coil leaving air condition of 55°F DB/54°F (53.3°F dew point), a dew point level that will likely be inadequate, especially considering the significantly reduced airflow rates inherent in chilled beam designs. However, DX-DOAS units configured with the capacity to properly dehumidify supply air, can be decoupled from a central plant supplying chilled water at elevated temperatures, significantly reducing a central plant’s kW/ton.

SmithGroup decided to demonstrate the value of this MEP concept for their office renovation. The challenge: Munters’ ended production of their commercial line in late 2018, a line that could supply and control air dew point down to 40°F. Another DX-DOAS solution was required. We decided on AnnexAir’s custom BioComposite DX-DOAS unit with variable speed compressor technology, as it could meet the required latent demand by supplying 45°F dew point air, and meet unit weight restrictions while meeting Phoenix’ Monsoon ambient wet bulb conditions and maintaining building dew point at 47°F. (Figure 7)

(Figure 7)

One concern, however, was the lack of available space on the roof for a conventional DOAS layout. DX-DOAS is often designed with a dual tunnel configuration with energy recovery allowing for a total building load reduction by approximately 25% in the Desert Southwest. For SmithGroup’s office, however, using energy recovery resulted in a footprint too large for the available roof space. Another consideration was the weight of the equipment on the existing roof. AnnexAir’s DOAS unit cabinet is constructed of a lightweight resin bio-composite material and insulation manufactured from recycled plastics. This significantly reduced unit weight eliminating the need for additional structural supports. (Figure 8)

(Figure 8)

However, the DOAS unit would have to provide brute force outside air cooling and heating efficiently for the chilled beam portion of the mechanical design to be justified. Another portion of SmithGroup’s office was conditioned by distributed water-source heat pumps from a central condenser water system. Instead of redesigning a water-source heat pump system for the client area, SmithGroup used the available condenser water for the DOAS unit to use a water-cooled compressor. The piping was rerouted a short distance to the roof for the DOAS unit. Reusing the condenser water is key to the high efficiency of the system. The DOAS unit was able to be designed with 12 EER and 5.6 COP efficiencies at actual operating conditions.

AnnexAir’s variable speed DX compressor technology met the demand and performance levels without heat recovery, and fit within the limited roof area. Chilled water was not available in this part of the complex, so a chilled water loop had to be created. A dedicated 10-ton Motivair air-cooled chiller was selected and decoupled from the DX-DOAS unit. This enabled the chiller to provide 58°F chilled water to the chilled beams and chilled boxes to meet the client space’s sensible demand. It’s elevated, leaving water temperature allowed the chiller to be more efficient than a traditional chiller design. The chiller had a part load efficiency of 16 IPLV at the rated ambient conditions of the harsh Phoenix environment. The air-cooled chiller reduced the need for additional water usage otherwise required for a high ambient environment. MERV 8 and MERV 13 filters were used in the DOAS unit to meet the LEED and WELL certification requirements as mentioned above.

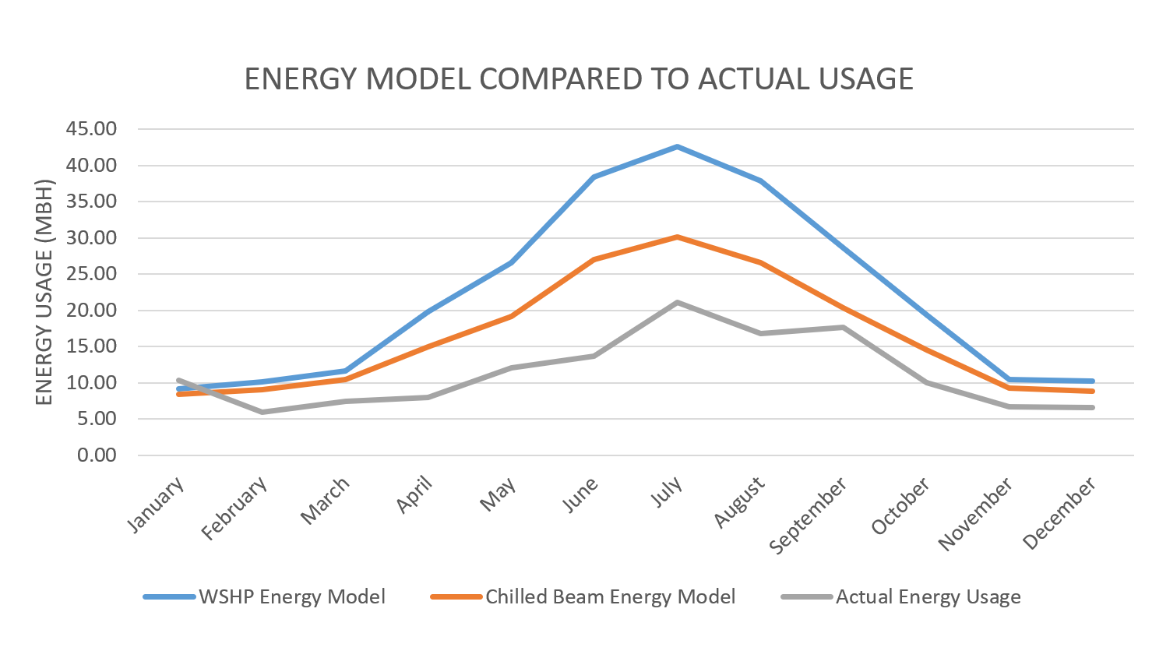

The proposed energy usage of the chilled beam design was modeled using Integrated Environmental Solution’s Virtual Environment and compared to the energy usage of a distributed water-source heat pump system that would have been installed in a conventional tenant improvement project. Modeled calculations showed a chilled beam system without a DOAS energy recovery section for the 5,000 ft² client spaces performed 25% more efficiently than a distributed water-source heat pump system. There were significant savings in the cooling and heating as expected. Another large savings was in fan energy since the DOAS unit is providing significantly less airflow than the heat pumps or a more common central AHU to a VAV system. The system energy usage is monitored and the chilled beam system operated less than what was predicted by the energy model. The energy usage in January was higher than the energy model due to the system being dialed in during the first winter of operation. The spring energy usage was lower due to the extended amount of economizer hours the DOAS unit was able to operate and the lower occupant usage. The summer energy usage was extended for a longer period of time due to the extraordinary hot summer that extended summer into October. (Figures 9 & 10)

(Figure 9)

(Figure 10)

The chilled water system conditions a combination of interior and exterior spaces. Chilled beams are used in the interior spaces.

(Figure 11)

It was determined that chilled beams could not properly condition the exterior spaces due to the high envelope loads of the existing glass and the high ambient temperatures. Chilled boxes often have a fractional horsepower fan with EC motors that recirculate air through a sensible cooling coil mounted at the induction inlet of the chilled box, providing more capacity than chilled beams. Chilled boxes were used in the exterior areas as they could provide the required conditioning and be connected to the high efficiency chilled water system.

Air distribution was at the forefront of the design team’s minds in the open office area. An executive conference room had a partial specialty ceiling that needed to be lower than the main ceiling. There was a concern that a lower ceiling would interfere with chilled beam air distribution and cause dumping over the conference room table. This was discussed early on in the project, and builders were able to be coordinate easily, by virtue of it being an integrated architectural and engineering firm. The chilled beam manufacturer tested the configuration at the factory with a ceiling lower than the chilled beam and was able to show that the lower ceiling would cause issues with the air distribution. The design team was able to coordinate the specialty ceiling to be flush with the main ceiling and provide proper air distribution in the room meeting ASHRAE 55 requirements.

ASHRAE and the Federal Government, historically, have continued to develop and update standards and codes to meet their stated net-zero carbon objectives. To meet these challenges, HVAC systems will need to be reexamined to see what new and adaptive technologies can be applied and incorporated into MEP systems to further reduce a building’s operational and embodied carbon footprint. Many of these technologies are not new. To increase system efficiency, however, invites more creative thinking, a reconnecting of the dots if you will. Examining more closely how a building’s sensible and latent loads can be more effectively met opens numerous design possibilities. SmithGroup invested in such a forward-thinking approach for their Phoenix office remodel project, and proved using an efficient and effective DX-DOAS technology to decouple a chilled beam system air handler from chilled water central plants offers one compelling design strategy to be considered when designing to meet our industries continually expanding standards and code criteria.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link