Key Takeaways

- District Steam Legacy: Con Edison operates the world’s largest district steam network, continuously running since 1882, with over 100 miles of underground mains serving Manhattan

- Safety First: The broom-handle technique for detecting invisible high-pressure steam leaks remains a critical safety practice that can prevent severe injuries

- Hidden Infrastructure: District systems eliminate individual building equipment, freeing valuable real estate while improving efficiency through centralized generation

- Future of Cooling: District cooling systems worldwide demonstrate proven efficiency gains, with potential applications for dense urban areas like NYC

The Downtown Manhattan Service Call

You get a service call. Downtown Manhattan. “No heat call.”

After thirty minutes of circling for parking, you finally wedge your van into a spot that feels like it was designed for a bicycle. You hop out to the sounds of the city traffic, honking horns, and an argument between a cabbie and his fare. The smell hits your nose—the combination of porta-potty and a Snoop Dogg concert. You throw your tool bag over your shoulder, triple-check that your van is locked, and find your building. You step into the building’s lobby, which has seen better decades. The Super barely looks up from his Daily Wordle puzzle and hands you an old brass key connected to a worn wooden block, then waves you toward the basement.

The crumbling cellar stairs are a hundred years old, and they look it. Cracked concrete, rust bleeding through paint, that damp musty smell that has been there so long it’s part of the building’s DNA. You head down into a maze of narrow corridors and odd little rooms that seem to have no purpose except to make you wonder what used to happen there. The air smells like mildew, machine oil, and something you cannot quite place—but you know it’s probably flammable.

Picture a similar room to the one Gary visits below, but darker, dustier, and rustier.

The Broom Handle Safety Check

Finally, you reach the “boiler” room door. Hanging beside it is an old wooden broom, handle worn smooth from years of dirty technician hands, dangling from a bent nail in the wall. It looks like something a witch might keep here for a quick getaway, but down here, it’s not for flying.

You take it down, hold it out at arm’s length in front of you, and push the door open. This is not superstition; it’s survival. In a steam plant, a high-pressure leak can be completely invisible but hot enough to burn through skin like a Sith’s lightsaber. The broom handle is your scout. If it suddenly sizzles or chars, you’ve just found a jet of superheated steam without finding it with your face. An old school trick, learned from techs who learned the hard way—similar to the safety practices we emphasize in our guide on nitrogen tank and gauge precautions.

You would think you’re stepping into a boiler room. Not here. This building doesn’t have one. It runs on district steam.

The Heat Beneath the Streets

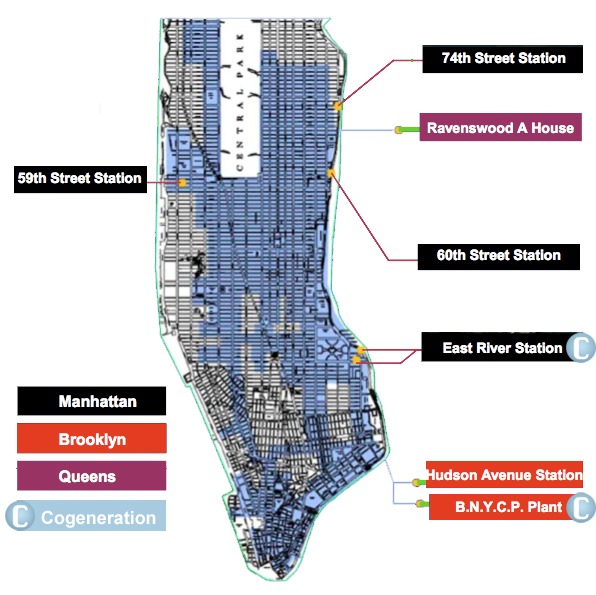

District steam is exactly what it sounds like: steam made at central plants and piped through the city to buildings that need it. In New York, that system is run by Con Edison, the utility company that has been powering and heating the city since the 1800s. Most people know them for keeping the lights on, but they also operate the largest district steam network in the world. It has been in continuous service since 1882.

Beneath Manhattan’s streets, the steam mains run in a hidden grid right alongside electric conduits, gas lines, and communication cables. The pipes are insulated and pressurized, carrying steam hot enough to heat skyscrapers, sterilize hospital equipment, and even drive cooling systems—much like the complex chilled water systems we’ve covered on the HVAC Know It All podcast.

How District Steam Works

Instead of each building firing up its own boiler, steam is generated at a handful of plants using:

- Natural gas

- Fuel oil

- Waste heat from electricity production

That steam travels through more than a hundred miles of mains, arriving at customer buildings ready to work. It can be:

- Piped directly into radiators or air handlers for heating

- Run through heat exchangers for domestic hot water

- Power absorption chillers that turn heat into chilled water for air conditioning

- Used by hospitals, labs, and food service operations for sterilization, humidification, and cooking

The system works here because Manhattan is dense and vertical. One central network is more efficient than thousands of individual boilers and chillers, and it frees up valuable real estate inside buildings. It’s also remarkably reliable—the network is looped and redundant, so service can continue even if a section is taken offline.

When Steam Systems Fail: The 2007 Catastrophe

Of course, steam isn’t all moonbeams and rainbows. When a steam main fails, it’s catastrophic.

On July 18, 2007, during the evening rush hour, a 24-inch steam main installed in 1924 ruptured beneath Lexington Avenue and 41st Street, near Grand Central Terminal. The explosion sent a geyser of superheated steam, mud, and debris 77 stories into the air, towering above the Chrysler Building. It created a 35-foot-wide crater, shook nearby buildings, and blanketed the area in asbestos-laced residue.

Amazingly, only one person died (of a heart attack while fleeing), and 45 others were injured, some severely burned. The chaos shut down blocks of Midtown, disrupted transit, and triggered fears of terrorism until officials confirmed it was a utility failure.

The Technical Cause: Bubble-Collapse Water Hammer

A later investigation revealed the cause: bubble-collapse water hammer. Here’s what happened:

- Heavy rain cooled the pipe and caused excess condensate to build up

- Two steam traps meant to drain that condensate were blocked by epoxy debris from a prior repair

- When steam re-entered the cooled pipe, it rapidly condensed, creating a vacuum

- The vacuum pulled water from both directions

- The resulting pressure spike, estimated at over 1,200 psi, ruptured the pipe

The scary danger of steam is that a high-pressure steam leak can be invisible, which is why that broomstick trick still lives on in old boiler rooms. It’s a simple, low-tech way to find a deadly hazard before it finds you—essential knowledge covered in our carbon monoxide testing guide.

The Cold Side of the Story: District Cooling Systems

If district steam is the old reliable workhorse under New York’s streets, district cooling is its cool distant cousin. Currently, New York doesn’t have citywide district chilled water, but the future may hold different plans. Same basic idea—a central plant with big insulated pipes piped to multiple buildings sharing the load—but instead of sending heat, you’re sending cold.

How District Cooling Works

A central plant produces chilled water, usually with high-efficiency electric or absorption chillers. That cold water is pumped through a network of underground pipes to customer buildings, where it runs through heat exchangers to cool the air. The warmed water then heads back to the plant to be cooled again.

Because the plant is serving dozens or even hundreds of buildings, it can use equipment and strategies you’d never see in a single building setup:

- Massive centrifugal chillers

- Thermal energy storage tanks

- Free cooling from lakes or seawater

- Heat recovery systems

Global District Cooling Examples

Toronto’s Deep Lake Water Cooling has been running for years, pulling icy water from deep in Lake Ontario to keep downtown skyscrapers comfortable. The system draws water from 83 meters deep where temperatures stay at 4°C year-round.

Paris has its own cold network under the streets, feeding chilled water to museums, hotels, and offices, including the Louvre. The system serves over 700 sites and is the largest in Europe.

In Dubai and Abu Dhabi, district cooling is practically the default for high-rise developments, helping keep the lights on and the AC running in extreme heat without crushing the electric grid. Tokyo’s Shinjuku district uses a massive heating and cooling network that flips between steam and chilled water depending on the season.

Even here in the U.S., you’ll find district cooling in:

- Chicago’s Loop

- Austin’s downtown

- University campuses from Florida to Minnesota

New York’s World Trade Center System

Right here in New York, the closest system to district chilled water is in the rebuilt World Trade Center. WTC has its own twist on the idea. Beneath the site are four massive intake pipes that run under West Street to the Hudson River, big enough for a worker to crawl through.

At peak demand, they can pull in up to 30,000 gallons of river water per minute. That water flows into the site’s central chiller plant, where it’s used to condense and cool the building systems that serve:

- The National September 11 Memorial & Museum

- The Transportation Hub

- Shopping concourses

- Security checkpoints

The system was designed for a century of service, and while environmental concerns led to scaling it back from the original plan, it still stands as a powerful example of how local resources can be harnessed for efficient, large-scale cooling—and as part of the living infrastructure of a place we will never forget.

Looking Ahead: The Future of District Energy

The benefits of district heating and cooling are hard to ignore:

- Efficiency: Central plants run at higher efficiency than dozens of small systems scattered around

- Grid Management: They can shift loads to avoid hammering the electric grid during peak hours

- Space Savings: Buildings don’t need to dedicate rooftop or basement space to boilers, chillers, or cooling towers

- Centralized Maintenance: Reduced maintenance burden on individual building owners

- Reliability: Redundant systems mean fewer complete failures

The flip side is that the infrastructure is expensive to build, and you need the right density of customers to make it work. But with cities getting hotter, electrical grids straining in summer, and sustainability targets getting tighter, it’s worth asking if we should be seeing more of this. Should district heating and cooling be a standard part of how we design dense urban areas?

For the Service Techs: Breaking It Down to Basics

If you’re a service tech walking into your first district steam or district cooling job, don’t let the scale throw you. Strip away the miles of mains and the central plants feeding them, and what you’re working on is something you already know (such as the example below):

District Steam Service

If you’ve piped a heat exchanger or water heater for domestic hot water, you’ve done this—the only difference is your heat source is coming from a plant somewhere else. If it’s direct-to-radiator steam, it’s the same principle you’ve seen a hundred times: supply in, condensate out.

District Cooling Service

If it’s chilled water, it’s just another loop—only the chiller is down the street or pulling from a river. The fittings might be bigger, the pressures higher, but the fundamentals are the same. Once you see it that way, these systems stop being mysterious and start feeling like just another part of your wheelhouse.

Ready to Level Up Your Commercial HVAC Skills?

Understanding district energy systems sets you apart in the commercial HVAC world. For technicians looking to expand their expertise, Property.com’s ‘Know Before You Go‘ tool provides detailed property insights that help you prepare for complex commercial calls. Join Property.com’s exclusive network to access advanced tools and connect with top-tier professionals specializing in large-scale systems.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link