Homeowners often assume the entire system has failed when a furnace won’t start on a cold morning. Many no-heat moments stem from a specific issue: a furnace gas valve problem that prevents the system from receiving the fuel it needs to operate. Despite its small size, the gas valve controls the most critical part of the heating cycle—releasing the correct amount of gas to the burners. Thus, the heat also stops when it stops functioning.

Furnaces in San Marcos are subjected to abrupt temperature fluctuations, humidity variations, and high usage. Those conditions put stress on internal components, making gas valve malfunctions more common than people realize. When they show up, they usually exhibit apparent gas valve malfunction symptoms, delayed ignition, or a furnace that repeatedly tries to start without lighting.

This guide explains how gas valves work, why they fail, and how this failure can grow into a larger, more expensive problem.

Understanding the Working of the Furnace Gas Valve

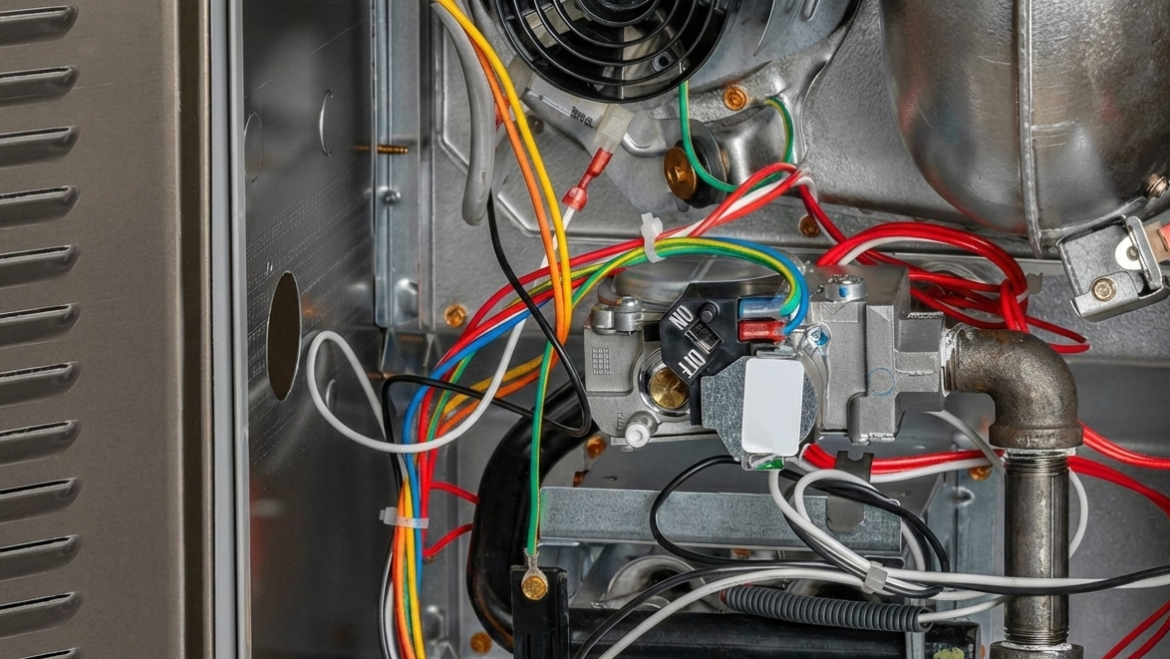

A furnace runs on precise timing. The thermostat calls for heat, the inducer motor clears the combustion chamber, and the ignition system activates. After the sensors confirm proper airflow and all safety checks pass, the control board sends a signal to the gas valve – only then does it open and release fuel to the burners. A gas valve includes two internal solenoids, a pressure regulator, safety shutoff mechanisms, and electrical connections to the control board. Any disruption in that sequence can cause problems with the furnace gas valve.

A properly functioning valve:

- Opens and closes only when commanded

- Delivers the correct gas pressure

- Works in sync with flame sensors, ignitors, and switches

- Reacts instantly to safety signals

Problems rarely show up on their own. When any part of the process fails, HVAC gas valve troubleshooting becomes essential for determining what’s really going on.

What are the Causes of Furnace Gas Valve Failure?

The following are the most common causes in residential systems, and each can disrupt the furnace’s ability to ignite or maintain a steady flame. When these issues go unchecked, they often lead to repeated shutdowns, inconsistent heating, and increasing safety risks.

1. Aging or Worn Internal Components

A furnace gas valve operates via small moving parts that open and close with each heating cycle. Heat exposure weakens the internal solenoids and, in some cases, can cause the furnace ignitor to crack, especially in older units. When these parts weaken, the valve reacts more slowly or inconsistently. Homeowners often notice delayed ignition, uneven burner flames, or short cycling long before the valve stops working completely. Age-related deterioration is one of the most common causes of gas valve malfunctions, especially in older systems that run heavily during Texas winters.

2. Electrical Failure or Loose Wiring

A gas valve relies on clean, steady voltage from the furnace’s control board. If a wire becomes loose, corroded, or damaged, the valve may not receive the signal it needs to open. Sometimes the signal becomes weak enough that the valve opens intermittently, creating repeated ignition attempts. These cases often mimic other gas valve malfunction symptoms, but the cause is purely electrical.

3. Contaminants Inside the Valve

Dust, rust particles, and debris inside the combustion chamber can migrate into the valve body over time. Texas homes with older furnaces or units installed in garages are more likely to experience this. When contaminants accumulate inside the valve, they interfere with the regulator or solenoid’s movement. This leads to unstable gas flow, rough ignition, or burner noise. Once debris enters the valve, it cannot be cleaned safely. Replacement becomes the only reliable repair.

4. Excessive Gas Pressure

Every gas valve is designed for a specific pressure range. If the supply line delivers gas at a higher pressure than intended, the valve must fight to regulate the flow. This creates internal stress and speeds up wear on the regulator. Excessive pressure produces symptoms like hard ignition, loud pops, or flames lifting off the burner. These problems will undoubtedly lead to long-term issues with the furnace gas valve, and the system will often fail pressure tests designed to ensure safety.

5. Moisture, Corrosion, or Rust Damage

Moisture is highly destructive to any gas valve. Condensation inside the furnace cabinet, improper venting, leaking humidifiers, or storage areas with poor insulation all expose the valve to humidity and rust. Corrosion within the valve body can cause the solenoids to stick or seize. Once corrosion starts, the valve becomes unreliable and may fail without warning. This is a critical safety issue and must be addressed by a professional immediately.

6. Faulty Ignitor or Flame Sensor

Not every gas valve failure is due to the valve itself being defective. A weak ignitor or a dirty flame sensor can cause the control board to shut off the valve before the burners ignite. Homeowners see this as repeated startup attempts or a furnace that runs the inducer but never lights. A gas valve opens only when the system detects the correct conditions, so communication issues between components often cause false failure signals.

7. Control Board Failure

The control board acts as the command center for the furnace. When the board fails to deliver a consistent output signal, the valve cannot open even if it is mechanically sound. Voltage drops, burnt traces, or surge damage on the board can cause miscommunication. The furnace may appear to run normally — inducer running, ignitor glowing — yet the furnace won’t ignite the gas valve because the board never completed the final command. This is another reason accurate diagnosis is essential before replacing major parts.

What Goes Wrong When a Furnace Gas Valve Fails?

Once a valve fails, the furnace stops producing heat. The burners never ignite, the control board locks out, and the homeowner typically hears repeated attempts to start with no success.

A failed valve also raises safety concerns:

- Gas may not shut off properly.

- Ignition can occur unpredictably.

- Combustion conditions become unstable.

This is why professional furnace repair services in San Marcos, TX treat gas valve issues as high-priority repairs, especially during peak cold weather.

Conclusion!

A furnace relies on a precise sequence to heat a home safely. When the gas valve weakens, sticks, or fails to respond, the entire system is affected. Understanding the furnace gas valve problems scenario helps homeowners act quickly before the furnace shuts down.

For lasting solutions, contact Woods Comfort Systems, the leading HVAC and plumbing company. We deliver reliable service backed by decades of hands-on knowledge and a strong reputation for customer satisfaction. Book your service now—enjoy peace of mind and get your heating system running smoothly again.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link