✕

At a latest assembly of the Worldwide Floor Supply Warmth Pump Affiliation (IGSPHA), Enertech enterprise growth supervisor Rob Derksen shared suggestions for a way HVAC contractors can turn into higher at selling geothermal warmth pump know-how. His first piece of recommendation was to teach the group. As geothermal warmth pumps achieve extra presence because the environmentally-conscious various for heating and cooling in business settings — reminiscent of faculties, residence buildings, lodges, and retirement properties — technicians and clients alike will should be knowledgeable on the fundamentals of how a water-source warmth pump (WSHP) works.

All Geothermal Techniques are Water-Supply Warmth Pumps, However Not All Water-Supply Warmth Pumps are Geothermal

On the coronary heart of each geothermal system is a warmth pump, and each geothermal warmth pump is “water-sourced,” which suggests they use water to take away warmth in cooling mode and so as to add warmth in heating mode. In geothermal, the supply of the water’s warmth and the “sink,” the place extra warmth is rejected, is the Earth. The water loop goes via pipes buried underground or submerged in a pond. If the system isn’t geothermal, then it makes use of a cooler and a sizzling water generator.

How a Warmth Pump Works

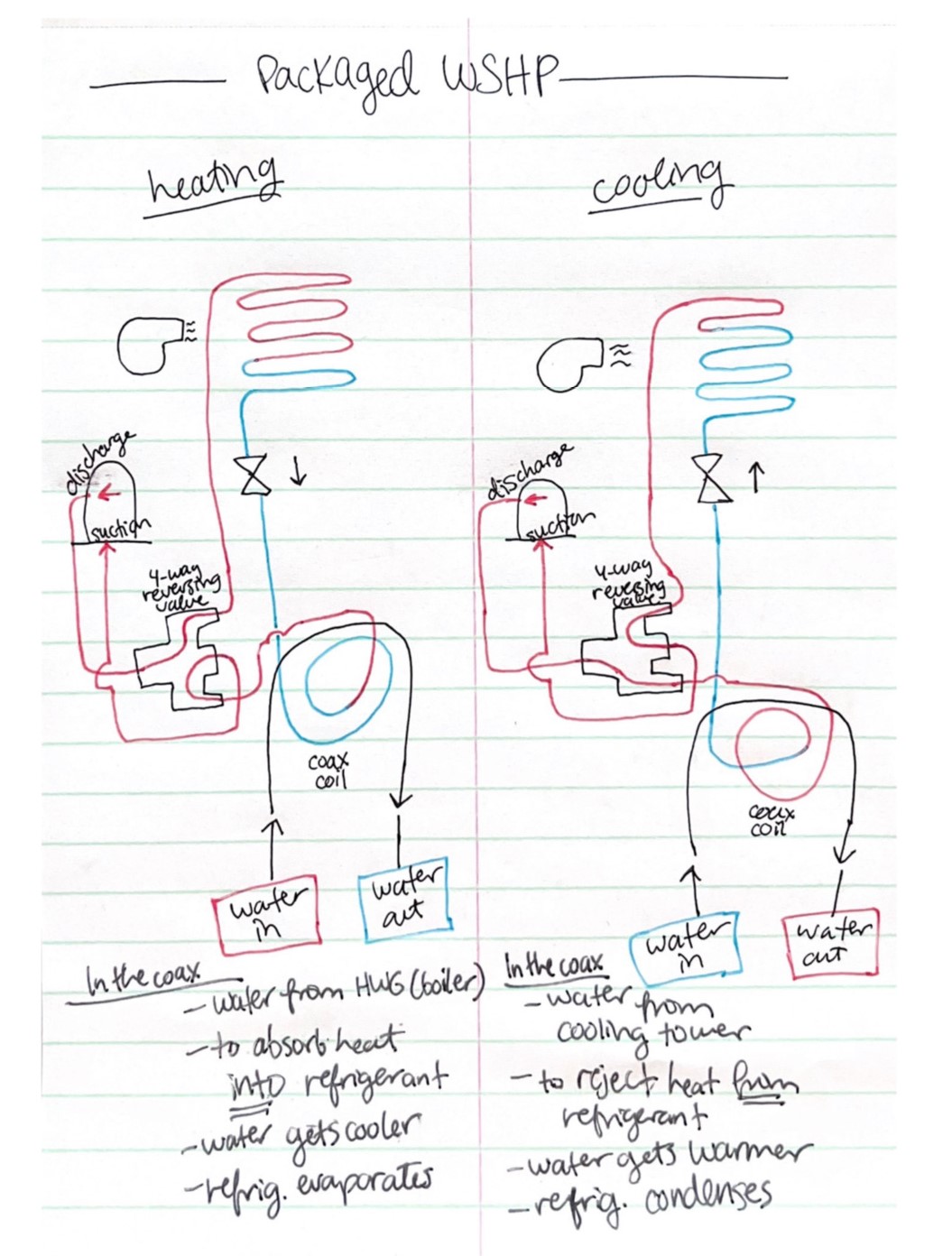

Warmth pumps use the refrigeration cycle to offer cooling identical to an everyday air conditioner; nevertheless, in heating, the warmth pump reverses this cycle to offer heat air for the area. This reversal happens when the 2 coils (the evaporator and condenser) change roles. As an alternative of sending sizzling refrigerant fuel to the condenser coil, the compressed refrigerant is shipped to the evaporator the place it rejects warmth into the area.

To perform the coil-switching, all warmth pumps have a four-way reversing valve (see Fig. 1). The valve at all times has one port by itself which has compressor discharge fuel going into the valve, and on the opposite aspect, there are three ports: one which directs refrigerant again to the compressor, and the opposite two going to every coil. The reversing valve is operated by a solenoid valve, which, when energized, strikes the valve to vary which coil the refrigerant goes to. Most warmth pumps energize the valve on a name for cooling. This manner, if the valve fails, it fails in heating mode. Producers usually program a five-minute delay between heating and cooling mode to stop put on and tear on the reversing valve.

FIGURE 1: The reversing valve is operated by a solenoid valve, which, when energized, strikes the valve to vary which coil the refrigerant goes to. (Courtesy of Lianna Schwalenberg)

How Water Absorbs and Rejects Warmth

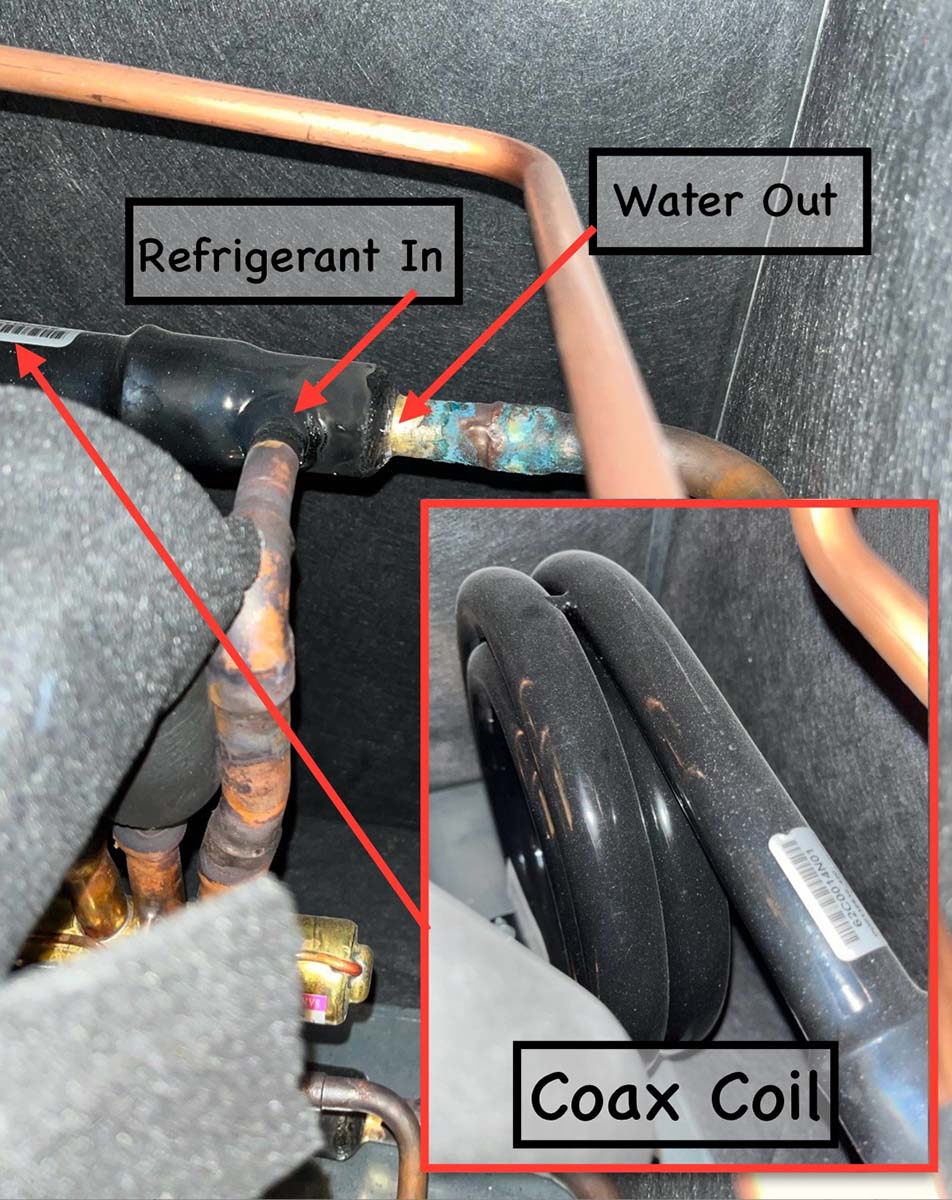

In WSHPs, the condenser is also known as a “coax coil.” It consists of two copper pipes spun collectively in a coiled loop form (see Fig. 2). With out mixing, that is how the water comes into contact with the refrigerant to soak up and reject warmth. The water and refrigerant stream counter to one another.

FIGURE 2: The coax coil consists of two copper pipes spun collectively in a coiled loop form. (Courtesy of Lianna Schwalenberg)

Just like how an everyday warmth pump works, water-source warmth pumps additionally use a reversing valve to vary the place compressed sizzling fuel refrigerant goes. In air-con mode, the WSHP sends sizzling fuel refrigerant to the coax coil the place warmth is rejected. In heating mode, the reversing valve sends compressed sizzling fuel refrigerant into the evaporator coil — which appears like a regular air coil — the place warmth from the refrigerant is rejected into the indoor area and the place the refrigerant condenses. After which, the condensed liquid refrigerant makes use of the warmth from the water coil to evaporate. And thus, the refrigeration cycle continues (see Fig. 3).

All WSHPs are “packaged” which means the unit comprises your entire refrigeration cycle. These models are sufficiently small to be put in in a closet or cupboard within the wall, making them an excellent possibility for apartment-style properties. Throughout set up, all that must be linked moreover {the electrical} and a condensate drainage system are two pipes: one for water-in and one for water-out. After all, the system additionally requires ductwork to distribute the air all through the area.

Click on diagram to enlarge

FIGURE 3: Warmth pumps use the refrigeration cycle to offer cooling identical to an everyday air conditioner; nevertheless, in heating, the warmth pump reverses this cycle to offer heat indoor air. (Courtesy of Lianna Schwalenberg)

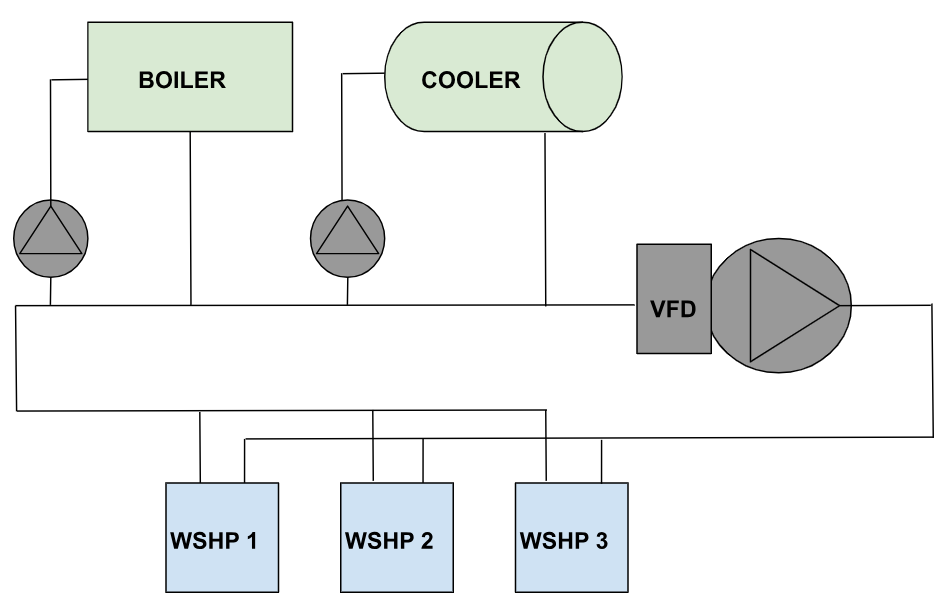

The Water Loop

The water is in a most important loop linked to a sizzling water generator — usually a boiler — and a cooler. The cooler generally is a closed-loop evaporative cooling tower, or a chiller system, which makes use of the refrigeration cycle to chill the loop water. The aim of the cooler and boiler is to keep up the water loop at a designed fixed temperature — between 65-95° Fahrenheit (generally 70°) — always, whatever the models’ calls for or the outside temperature (see Fig. 4). This water loop acts as each a “sink” and “supply” of warmth power.

It might shock some to suppose that 70° can accomplish each heating and cooling. Nonetheless, as a result of these programs use the refrigeration cycle, 70° truly has a major quantity of “area” to carry and provides warmth. Consider it like working an air conditioner when it’s 70° exterior or likewise working a warmth pump in heating when it’s 70° exterior. Identical to with air, this too may be achieved with water.

If the constructing is many tales tall, there’ll usually be custom-built pump skids on each ground or each different ground to keep up stream with out the necessity for terribly massive pumps or boilers and chillers on each ground. If the loop water ever has to go exterior, typically the water will probably be combined with glycol to decrease its freezing level.

FIGURE 4: The first function of the chiller and boiler is to keep up the water loop at a relentless temperature always, no matter all of the models’ calls for or the temperature exterior. (Courtesy of Lianna Schwalenberg)

Upkeep Issues

Like several air-handling system, these models have air filters that have to be modified often. These models even have wye strainers on the water-inlet aspect to catch particles. To take away the wye strainer display, flip off the valve, bleed the stress and use two wrenches to take away the cap. These strainer screens don’t essentially should be cleaned as typically the filters are modified. Checking a temperature or PSI differential will point out if they’re clogged. The temperature distinction between the incoming and outgoing water is often 10°. A 20° distinction or extra is an indication that the strainer display might be restricted.

As with sustaining an everyday air conditioner, it is usually good observe to examine the evaporator drain pan and ensure it’s clear and drains properly.

– Lianna Schwalenberg

HVAC service technician

The Okay Firm

Troubleshooting

The commonest issues are the next: poor water stream, poor airflow, refrigerant leaks, water leaks, and part failures. It’s endorsed to have a spare unit on website in case an element fails in emergency conditions. Water stream issues are akin to a grimy condenser coil whereby the switch of warmth is restricted.

As a result of these programs are very small–usually solely a pair kilos of refrigerant–the really useful option to examine cost is to first examine the temperature rise and drop. As with every warmth pump, the temperature rise isn’t as spectacular as a fuel furnace, however in each heating and cooling, you’ll usually see 20-30° splits between return and provide air. If the temperature cut up could be very low, and after you’ve gotten dominated out air-flow and water-flow issues, then you should utilize a low-loss becoming or a thumbscrew core depressor to examine the cost. These instruments stop refrigerant from escaping which is particularly vital to contemplate if you end up in an area as small as an residence lounge or hallway closet. These programs at all times arrive factory-charged, and since there aren’t any line units, you’ll usually not have or want a charging chart. A WSHP that’s low on refrigerant behaves the identical method as an everyday air conditioner low on cost, and when it’s time to add the cost, merely weigh it in.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Supply hyperlink

Add Comment