This article is Part 3 of a 3-part series on heat load calculations and proper HVAC sizing by Drew Tozer for HVAC Know It All. Read Part 1 & Part 2.

A Common Factor, Then a Theory

When I was completing energy assessments for homeowners, I noticed that the modelled energy consumption was frequently 20x the gas consumption.

I assumed it was a coincidence, and I didn’t dig into the data.

I also didn’t have a way to check the numbers on a bigger scale. But heat load calculators that were based on the same methodology started to be released, which gave me the opportunity to test my theory (~20x the gas consumption).

I used thermalpoint.ca (developed as a collaboration in Toronto between TRCA, STEP, and TAF). It’s a calculator for Ontario homeowners–it follows the same process but it does the HDD lookup in the backend.

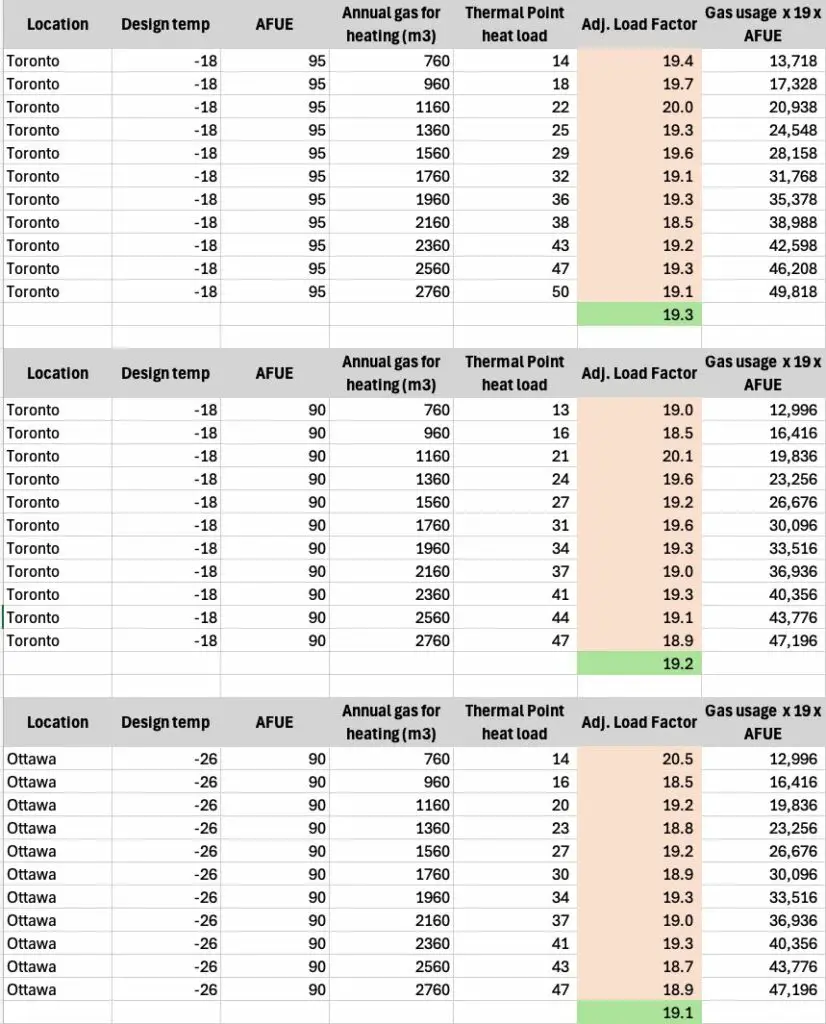

See the image below. I recorded heat loads (output) for different scenarios:

- 200 m³ increments from 1,000 – 3,000 m³

- Compared 90% and 95% AFUE (efficiency rating)

- Compared Toronto, Ottawa, and Thunder Bay (not shown)

Look at the results!

The “load factor” is 19 across every scenario. I adjusted the results to exclude AFUE, so the heat load calculation would be: gas usage * 19 * AFUE.

Assuming AFUE of the existing equipment is around 92%, we get the magic 17.5 heat load factor for Toronto.

I ran the test in reverse, using the heat load factor to calculate heating loads, and comparing it to the output from the calculator. The results were +/- 1,000 BTU/hr.

The results were similar in Toronto, Ottawa, and Thunder Bay. That surprised me, given the difference in design temperatures (4°F, -7°F, and -16°F, respectively).

My best guess is that the two temperature metrics roughly cancel out. The calculation includes “heating degree days” in the numerator and “indoor set point minus design temperature” in the denominator. I expect they’re strongly correlated within a climate zone.

Next Steps: Calculate Your Heat Load Factor

Let’s talk about a shortcut for the quoting process. Do the full calculation for the next 10 projects. Choose projects with common AFUE ratings like 90-96%.

Once you have all 10, write them in an Excel sheet with three columns: gas usage, heat load, and heat load factor. You already have gas usage and heating load. To get the heat load factor, divide heating load by gas usage (therms or m³).

How does it look?

Are the numbers in the third column consistent? You can check for outliers, but otherwise take the average.

That’s your local Heat Load Factor (HLF).

Now you have a shortcut for accurate heat loads.

A method to do accurate heat load calculations in 10 seconds or less.

Ask the homeowner for their annual gas usage, adjust for gas water heating (minus 300 m³ or 100 therms), and multiply by your calculated HLF.

I added “annual gas usage” and “water heat fuel type” to my company’s Homeowner Intake Form, so I get the information upfront. Now I confidently give virtual quotes for right-sized heat pumps.

And if you don’t have a dynamic Homeowner Intake Form, get one!

Real-World Application

Let’s look at an example. A Toronto homeowner who wants a heat pump to replace their furnace and AC. From their Homeowner Intake Form we know:

- Annual gas usage: 1,300 m³ (460 therms)

- Does the furnace have plastic exhaust pipes or metal? Plastic (i.e. it’s likely 90-97% efficient)

- Water heating fuel? Electric

Take a second. What equipment do we quote?

The heat load factor in Toronto is 17.5x (50x), it’s a high-efficiency furnace, and there’s no adjustment needed for water heating (it’s electric, not gas).

Answer: I’d confidently quote a 2-ton heat pump to cover the ~23,000 BTU/hr heat load (1,300 x 17.5 or 460 x 50 = 23,000).

Yes, I copied the gas usage from the story in the introduction. The one where the contractor quoted a 7-ton gas furnace. We got a slightly different answer (23 KBTU versus 26 KBTU), but it’d lead to the same equipment. Again, the goal is close enough.

Even if you don’t use heat load factors as your only sizing criteria (note: you shouldn’t), it’s extremely useful as a sizing rule-of-thumb for HVAC in cold climates. You’ll immediately know that a Toronto house with 1,300 m³ (460 therms) of gas heating needs a 2-ton heat pump, not a 7-ton furnace.

Why This Matters for System Performance

Traditional rules-of-thumb for sizing (like 1 ton per 400 sqft) are useless because they’re based on data that doesn’t directly impact heat loads. A modern, well-built 3,000 sqft house that’s airtight and well-insulated may need less heat than an old 1,000 sqft bungalow that’s leaky and uninsulated.

A rule-of-thumb based on square footage won’t reflect that—but gas usage will reflect how the house performs under real-world conditions.

This illustrates perfectly why right-sized equipment matters, especially when transitioning to heat pumps. The solution, as Gary suggests, is to “size closer to the cooling load but as close to the heating load as possible” and supplement with auxiliary heat when needed.

Limitations and Adjustments

First, this works best for heating-dominated climates. Warm climates have an extra variable that complicates everything: humidity.

Second, pay attention to indoor setpoints. Homeowners that keep the thermostat at 65°F all winter will throw off the calculation. You can adjust the HDD baseline to account for extreme setpoints.

And third, gas consumption directly correlates to winter temperatures, so we need to adjust the heat load factor annually based on the coldness of each winter. The amount of cold that the house had to fight against to stay warm all winter. We can use heating degree days to assess “coldness”.

The heat load factor for Toronto is 17.5x (50x) for 2024 gas consumption. If 2025 is 10% colder (i.e. 10% more heating degree days), adjust the heat load factor down by 10%.

Notice that it’s an inverse relationship because more HDD means colder. A 10% increase in HDD results in a 10% decrease in the HLF—a colder winter naturally forces every house to use more energy for heating, so the same gas usage in a colder winter means a higher performing house (i.e. lower heat load).

Avoiding Common Heat Pump Sizing Mistakes

This approach helps avoid one of the most common mistakes in HVAC: oversizing equipment. As explained in the HVAC Know It All article on heat pump oversizing, “Many oversizing issues stem from incorrectly performed load calculations. A concerning practice involves deliberately ‘manipulating’ Manual J calculations to justify larger equipment.”

Using real-world energy consumption data provides a reality check against these inflated calculations. The Heat Load Factor method gives you a realistic starting point that can be validated with other assessment methods during your site visit.

For a deeper dive into proper heat pump sizing and installation considerations, check out the podcast below where Gary and I discuss how systems should be sized with care, not guesswork, so homes stay comfy, air stays clean, and systems last longer without costly breakdowns.

Final Thoughts

Now that you know all the shortcuts to load calculations, put it into practice in your HVAC business:

- Integrate With Existing Processes – Ask about gas consumption in your intake forms to gather the data needed for Heat Load Factor calculations upfront.

- Provide Confident Virtual Quotes – Leverage performance-based calculations to deliver accurate equipment sizing recommendations remotely, but a disclaimer on virtual quotes that final pricing requires a site visit to confirm measurements and logistics.

- Pre-Qualify Customers – Use the Heat Load Factor method and virtual quotes to quickly identify and avoid price-shopping customers seeking the lowest bid regardless of proper sizing.

- Streamline Premium Service – Position yourself as a premium contractor by offering accurate heat pump sizing quotes without time-consuming initial site visits.

- Assess Infrastructure Limitations – During the site visit, measure existing ductwork and static pressure during your final site assessment to validate your heat load factor calculations. And confirm that the electrical panel can support the recommended setup.

By consistently using this approach, you’ll avoid the comfort issues associated with oversized equipment while ensuring your heat pump installations perform as designed. Your customers will appreciate the improved comfort, and you’ll build a reputation for installing systems that actually work as intended.

This article is Part 3 of a 3-part series on heat load calculations and proper HVAC sizing by Drew Tozer for HVAC Know It All. Read Part 1 & Part 2.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link