Key Takeaways

- The 35% Rule: Single-stage equipment requires the smallest zone to handle at least 35% of total system CFM to prevent equipment damage from excessive static pressure

- Bypass Sizing Formula: Calculate bypass duct requirements using (Equipment tonnage × 300 CFM) – Smallest zone CFM to prevent catastrophic pressure buildup

- Load Calculations Matter: Perform individual Manual J calculations for each zone, not just the whole house – zone diversity factors can reduce peak loads by 7%

- Equipment Selection: Variable-speed systems eliminate most airflow constraints, while single-stage equipment requires careful zone sizing and bypass damper design

Multi-zone HVAC systems promise customized comfort for every room, but the reality is far more complex than slapping a few motorized dampers in the ductwork. Get it wrong, and you’ll create more problems than you solve – from frozen coils to premature compressor failure.

Understanding the Fundamentals of Zone System Design

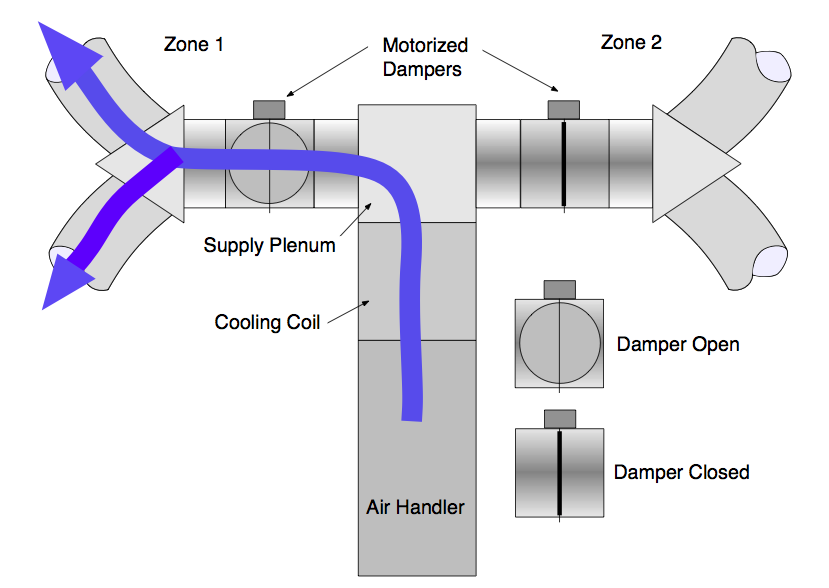

Multi-zone systems work by controlling airflow to different areas of a building independently. While the concept sounds simple, the execution requires careful engineering to prevent equipment damage and ensure proper operation.

The most critical rule in zone system design is the 35% minimum airflow requirement. When using single-stage equipment, your smallest zone must be able to handle at least 35% of the total system CFM. This isn’t a suggestion – it’s a hard requirement to prevent excessive static pressure buildup when only that smallest zone calls for conditioning.

Think about what happens when zone dampers close: the same blower that was pushing air through 2,000 CFM of ductwork suddenly faces resistance. Static pressure skyrockets, potentially exceeding the 0.8″ WC danger threshold where equipment damage becomes likely. You’ll see a 10% CFM reduction for every 0.1″ WC increase above 0.7″ – leading to frozen evaporator coils in cooling mode or overheated heat exchangers during heating.

For technicians familiar with troubleshooting gas-fired ignition problems, you know how critical proper airflow is for combustion safety. Zone systems add another layer of complexity to maintaining safe operation.

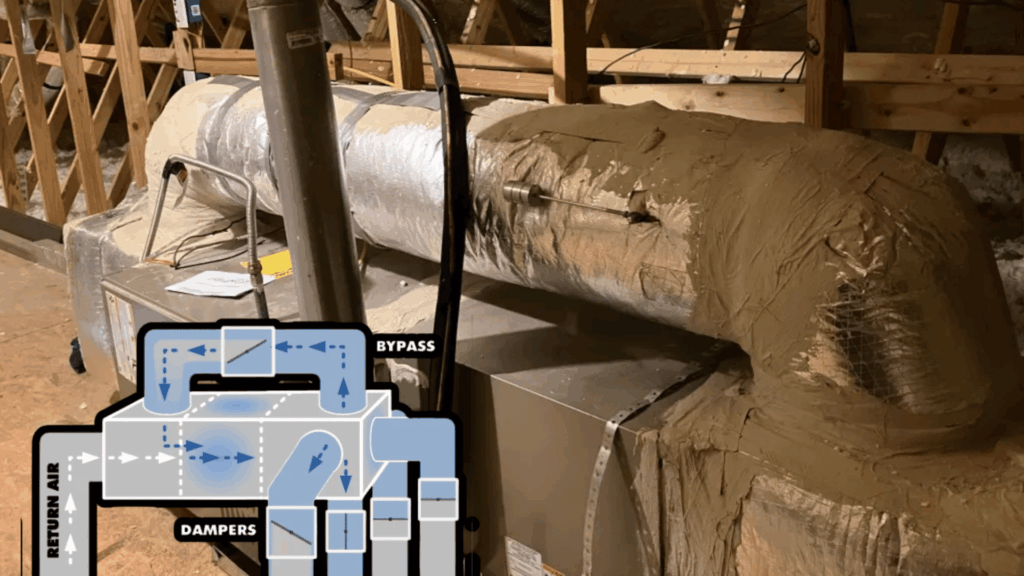

The Bypass Duct: Your Safety Valve

Every single-stage zoned system needs a properly sized bypass duct. Here’s the formula that could save you from a callback nightmare:

Base Minimum CFM = Equipment tonnage × 300 CFM/ton

Bypass CFM = Base Minimum CFM - Smallest zone's maximum CFM

For a 3-ton system with a 400 CFM smallest zone:

- Base requirement: 3 × 300 = 900 CFM

- Bypass needed: 900 – 400 = 500 CFM

- Duct size: 8-inch round (or equivalent rectangular)

The bypass must be installed at least 8 feet from both supply and return plenums when possible, with a balancing damper for fine-tuning. This isn’t optional – manufacturers rate electric air handlers as low as 0.3″ WC maximum and gas furnaces typically at 0.5″ WC. Exceed these limits and you’re looking at motor stress, reduced efficiency, and potential warranty voids.

Related Video: How to Check External Static Pressure on HVAC Equipment

Load Calculations: The Foundation of Success

Here’s where many contractors stumble: using a single Manual J calculation for the entire house, then arbitrarily dividing capacity among zones. This approach ignores diversity factors – the fact that not all zones peak simultaneously.

Proper design requires:

- Individual Manual J calculations for each zone

- Application of diversity factors (typically 70-85% for lighting, 42-89% for receptacles)

- Equipment sizing based on coincident peak loads, not the sum of individual peaks

- Distribution design following Manual D with zone-specific considerations

ACCA’s Manual Zr provides the framework, but understanding the practical application separates successful installations from problematic ones. When working with heat pump systems, remember that zone loads affect both heating and cooling capacity requirements differently.

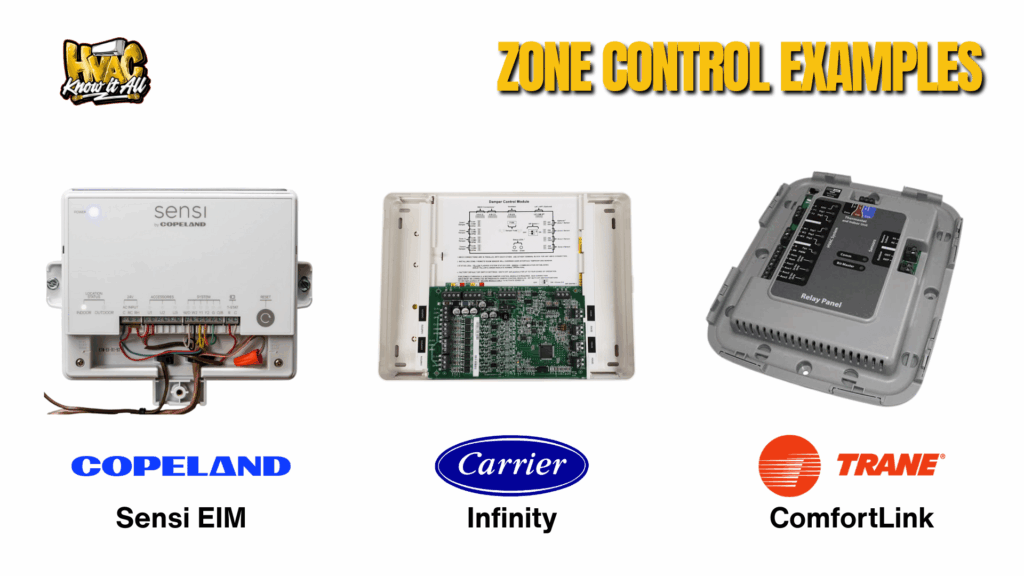

Choosing Your Control System

The market offers three distinct philosophies in zone control:

- Universal Systems (like Copeland’s Equipment Interface Module) provide maximum flexibility through wireless connectivity that eliminates traditional wiring constraints. The EIM bridges the gap between smart thermostats and existing equipment, enabling zone control without pulling new wires. Perfect for retrofits where you’re working with existing equipment or dealing with challenging wire runs.

- Proprietary Systems (like Carrier Infinity) require matched equipment but deliver superior performance through continuous communication between components. The variable fan speed control per zone alone can justify the premium for new construction.

- Hybrid Approaches (like Trane ComfortLink) balance compatibility with advanced features, supporting 6 zones with auto-sizing capabilities and smart home integration.

Your choice depends on the specific application. Retrofitting an older system? Universal controls make sense. New construction with a quality-focused customer? Consider the benefits of a proprietary system with its 10-year parts warranty and learning algorithms.

Installation Best Practices

Success lies in the details:

- Damper Selection: Power dampers with Belimo actuators use 25% less power than spring-return models while providing more precise control

- Static Pressure Monitoring: Install sensors in both supply and return plenums

- Safety Controls: Supply air sensors prevent coil freeze-up and heat exchanger overheating

- Wiring: Run dedicated 18/5 thermostat cable for each zone – never daisy chain

- Documentation: Create detailed zone maps showing damper locations and control wiring

Remember: Zone systems must maintain minimum airflow to prevent refrigerant issues.

Related Video: Multi-Zone Ductless HVAC Installation Best Practices

Commissioning: Where Theory Meets Reality

Proper commissioning separates professional installations from “chuck and truck” operations:

- Pre-Start Inspection: Verify all dampers fully open, check wiring connections

- All Zones Calling Test: Set thermostats to 55°F for cooling, measure airflow at each register

- Individual Zone Testing: Cycle through combinations, verify bypass operation

- Static Pressure Verification: Confirm readings stay within manufacturer specifications

- Documentation: Complete TAB reports with damper positions and system pressures

This process adds 25% to installation labor but ensures optimal performance and customer satisfaction. When customers understand you’re following industry best practices for system longevity, they appreciate the professional approach.

The Variable-Speed Alternative

While single-stage zoning requires careful engineering, variable-speed equipment is a different story. These systems modulate capacity to match zone demands, eliminating most airflow constraints. The premium pays for itself through:

- Reduced callbacks from comfort complaints

- Lower energy consumption

- Simplified installation without bypass requirements

- Extended equipment life from reduced cycling

Moving Forward

Multi-zone HVAC systems offer tremendous benefits when properly designed and installed. The key is understanding that zoning isn’t just about adding dampers – it’s about creating a complete system that respects equipment limitations while delivering promised comfort.

Start with proper load calculations, size your bypass correctly, choose appropriate controls, and commission thoroughly. Follow these principles, and you’ll deliver systems that perform reliably for years while building your reputation as a true professional.

Growing your business means tackling complex installations with confidence. Property.com’s ‘Know Before You Go‘ tool provides critical property insights that help identify zoning opportunities and potential challenges before you provide estimates. From room additions that create comfort problems to previous HVAC work that might complicate installations, having complete property intelligence helps you deliver accurate quotes and superior solutions.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link