✕

– Scott Martin

Senior director of trade relations and compliance

Hillphoenix

Carbon dioxide (CO2) has been used as a secure and dependable refrigerant for the reason that Industrial Revolution. Now, trendy meals retailers are adopting CO2 (R-744) as their most well-liked refrigerant — and for good cause. The checklist of benefits of utilizing CO2 is complete:

- It’s a pure refrigerant;

- It’s an odorless, non-corrosive, non-toxic, and nonflammable Class A1 refrigerant;

- It has no ODP and with a GWP of 1, it’s the foundation by which all different refrigerants are measured;

- Its excessive heat-reclaim capabilities enhance stored-energy efficiency;

- It presents vital power and operational value financial savings;

- It has low service and upkeep prices since it may be vented to the environment and doesn’t need to be captured or reclaimed; and

- It doesn’t run afoul of regulatory points, so finish customers gained’t be topic to fines or penalties. As such, it’s future-proof.

CO2 refrigerants began competing with “artificial refrigerants” within the Nineteen Thirties, with the creation of chlorofluorocarbons (CFCs). CFCs ultimately gave solution to hydrofluorocarbon (HFC) refrigerants, which have been thought-about extra secure and extra dependable within the greater ambient temperatures under the so-called “CO2 Equator.”

Consequently, CO2 began to be seen as a secondary refrigerant. Nonetheless, a sequence of technological improvements — coupled with the dangerous results HFCs have on the surroundings — helped restore CO2’s standing as a scalable sustainable refrigerant. Nonetheless, misconceptions proceed to encompass the usage of CO2 in refrigeration programs, and a few of these myths will likely be debunked right here.

Delusion: Transcritical CO2 Can’t Be Used Under the CO2 Equator

As a result of ambient temperatures improve the nearer one will get to the Equator, the argument goes that transcritical CO2 programs shouldn’t be used under the CO2 Equator. As a substitute, many consider {that a} subcritical CO2 system must be used, which is one wherein the refrigerant will be condensed.

Issues across the CO2 Equator began to vanish about 10 years in the past, resulting from a sequence of technological advances that included:

- Adiabatic fuel coolers, which mix the condensing of the refrigerant with the adiabatic cooling of the air;

- Excessive-pressure subcoolers, which use a small mechanical vapor-compression cycle coupled to the primary cycle on the exit level of the condenser to supply subcooling;

- Parallel compression programs, which compress extra (flash) fuel on the highest stress stage potential to enhance general power effectivity; and

- Gasoline ejector programs, which get well the power of the high-pressure aspect of the system to cut back the work required on the lower-pressure aspect of the system.

Actuality: The CO2 Equator fable is now not related, because of advances in refrigeration system expertise.

Delusion: CO2 Requires Considerably Extra Power vs. Conventional Refrigerants

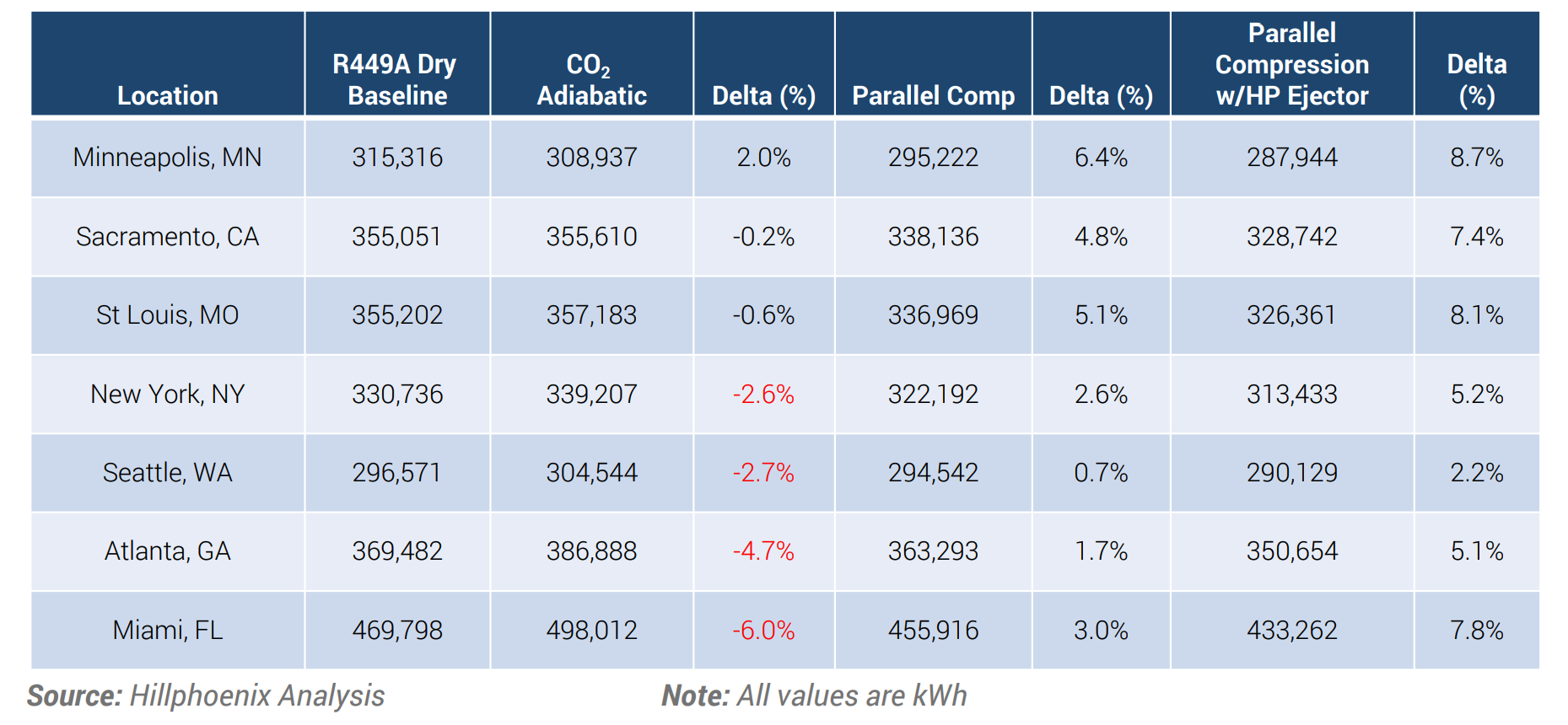

Perceptions typically form beliefs, but a comparability between a system using R-449A, a mix of HFOs and HFCs, and one using CO2 refrigerant, sheds gentle on these distinctions. Aspect-by-side checks carried out throughout seven U.S. cities (Minneapolis, Sacramento, St. Louis, New York, Seattle, Atlanta, and Miami) confirmed that when improperly put in, a CO2 system will be 17% (in Seattle) to 22% (Miami) much less environment friendly than an R-449A system.

Nonetheless, when the CO2 system is correctly designed and consists of elements, corresponding to adiabatic fuel coolers, parallel compressors, parallel compressors with high-pressure ejectors, and digital enlargement valves (EEVs) the CO2 system will be extra environment friendly than the R-449A system. The issue is that many operators will mistakenly measurement their CO2 system based on HFC system parameters.

Actuality: There are quite a few energy-saving potentialities when CO2 refrigerant is utilized in a correctly designed system, and the advantages will be compounded when further elements are employed.

Click on chart to enlarge

IMPROPER INSTALL: Aspect-by-side checks carried out throughout seven U.S. cities confirmed that when improperly put in, a CO2 system will be much less environment friendly than an R-449A system. (Courtesy of Hillphoenix)

Delusion: Power Consumption Will increase Considerably When a CO2 System Goes Supercritical

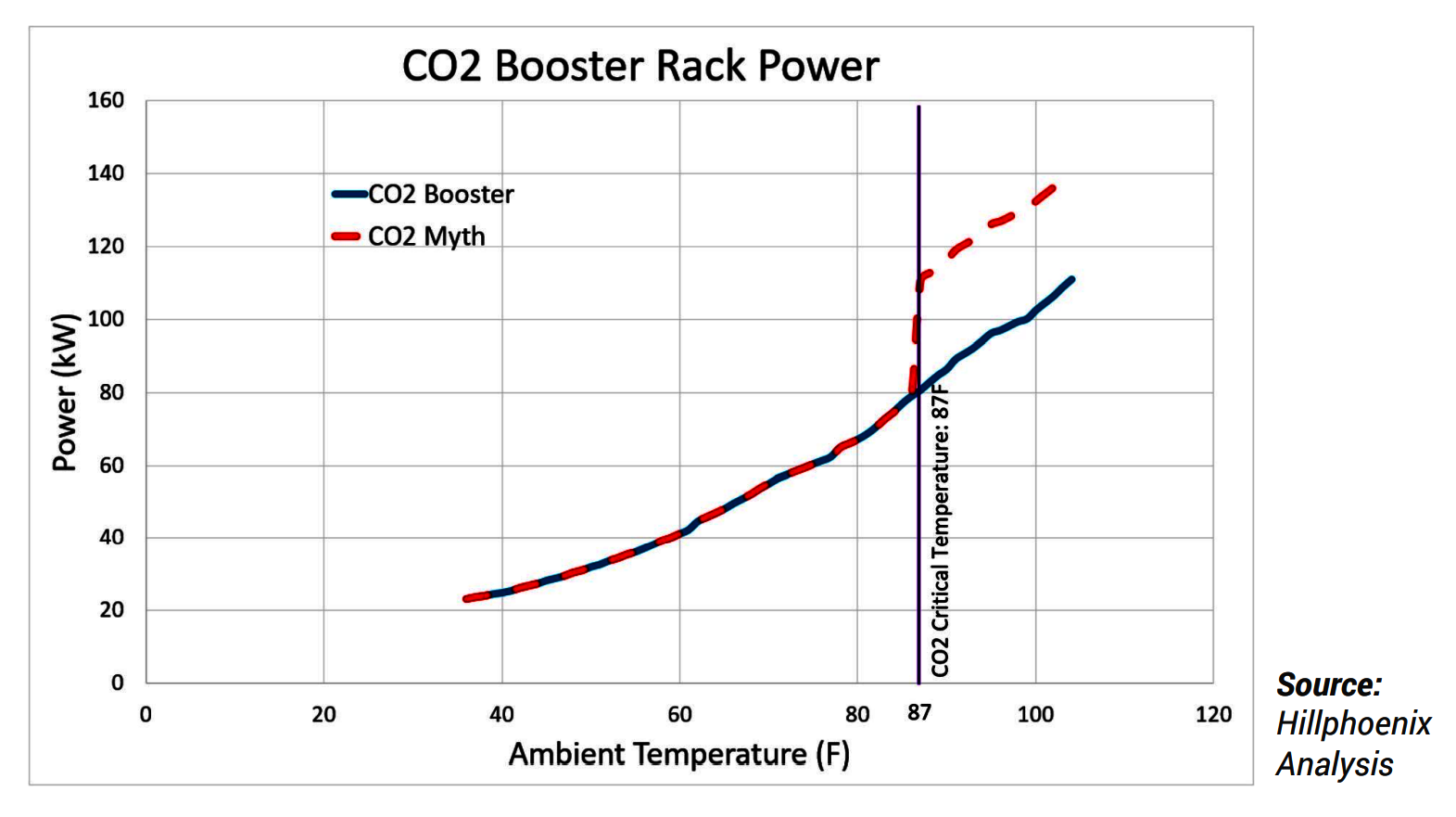

Because the subcritical ambient temperature (lower than 87ºF) across the refrigerant system strikes towards the supercritical CO2 temperature of 87ºF, the idea is that there will likely be a major and instant spike in power utilization when the subcritical/supercritical line is crossed. This made meals retailers nervous, particularly in hotter climates. However when examined, the outcomes present that so-called vital spike doesn’t occur.

Actuality: Whereas kilowatt (kW) utilization does improve because the supercritical temperature threshold is handed, no drastic spike is skilled. Power consumption will increase alongside the identical regular path because it does in subcritical temperatures — identical to another refrigerant.

Click on chart to enlarge

NO SPIKE: Whereas kilowatt utilization does improve because the supercritical temperature threshold is handed, no drastic spike is skilled. (Courtesy of Hillphoenix)

Delusion: CO2 Refrigeration Methods Are Too Advanced

Schematic drawings of a typical CO2 system can look advanced, as they function a number of valves (high-pressure, digital enlargement, and flash-gas bypass), transcritical and subcritical compressors, case and rack controllers, coolers, condensers, and warmth reclaim programs. That may sound like loads to maintain observe of; nonetheless, advances in expertise have additionally busted this fable.

The important thing innovation right here is the EEV, which is way simpler to work with than mechanical valves. Additionally, CO2 refrigerant programs can now be managed and optimized by computer systems, which suggests each system perform is learn by way of transducers, temperature sensors, and analog and digital inputs. Operation is reported/recorded by way of digital software program and {hardware}, so an efficient computer-controlled system is all you could guarantee correct operation. That eliminates the necessity for a technician to always monitor and manually modify the system’s valves and different elements.

Actuality: Whereas the design and elements of CO2 refrigerant programs are just like these used for a few years, electronically managed elements make them extra dependable and provides them longer service life. This leads to a decidedly much less advanced and extra strong system.

Keep tuned for Half 2 of this text, which can dispel much more myths about CO2 refrigeration programs.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Supply hyperlink

Add Comment