✕

This 12 months’s AHR Expo acknowledged, for its prestigious Innovation Award, Infinicon’s FLUE Mate combustion analyzer because the winner of the Instruments & Devices class. Combustion analyzers have gotten an increasing number of prevalent in service vans internationally as a result of rising issues concerning the security and effectivity of gasoline furnaces. Because the measurement instruments proceed to enhance, it is very important perceive the fundamentals and the way a combustion analyzer works.

Theoretical Combustion

Theoretical, or “stoichiometric,” combustion between an ignited hydrocarbon (reminiscent of methane in pure gasoline, and petroleum in residence heating oil) within the presence of oxygen, produces solely three issues: warmth power, carbon dioxide, and water.

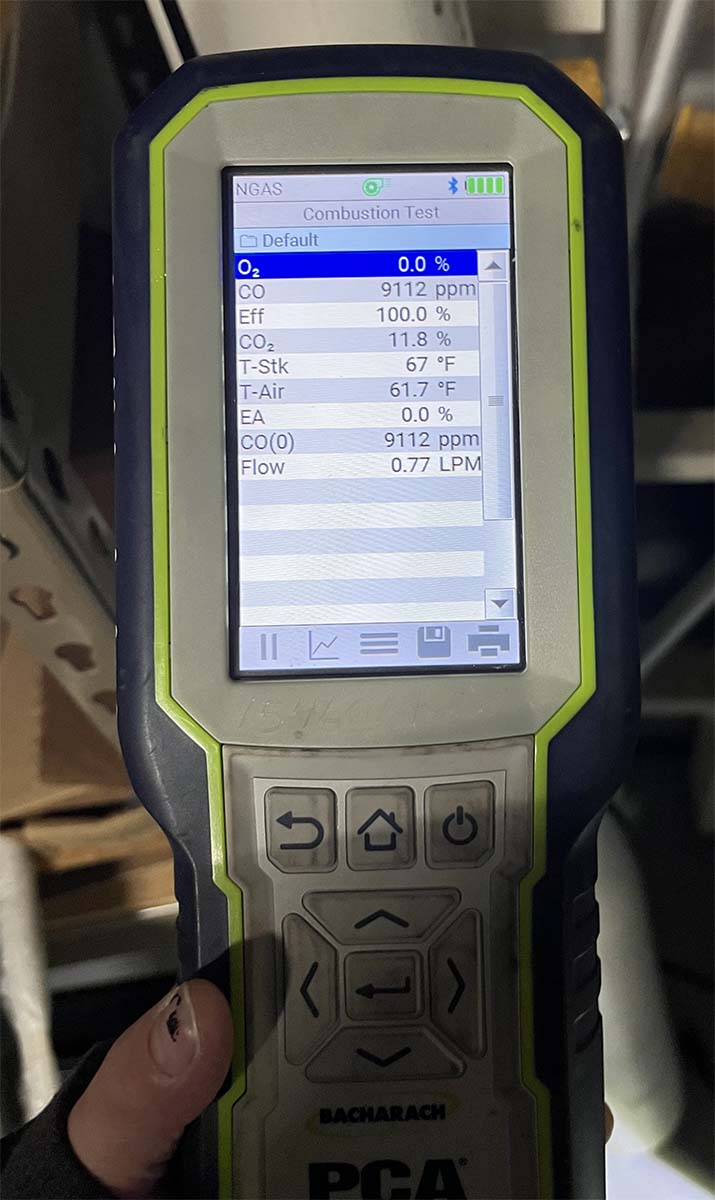

FROM DATA TO ACTION: Technicians ought to familiarize themselves with what constitutes a typical or unhealthy studying for particular purposes. (Courtesy of Lianna Schwalenberg)

As a result of air comprises largely nitrogen, a nonflammable gasoline, and solely about 20.9% oxygen, nature makes it extraordinarily tough to combine the precise quantity of gasoline strain and oxygen. Due to this, the combustion course of within the discipline is all the time stated to be “incomplete.” Consequently, there’s all the time a small launch of partially oxidized compounds, reminiscent of carbon monoxide, together with the carbon dioxide and water on this course of.

An excessive amount of gasoline, too little gasoline, an excessive amount of air, and too little air will all trigger carbon monoxide. Carbon monoxide not solely makes folks sick and in extra can result in dying, however it’s also an indication there’s something incorrect with the furnace – normally one or a mixture of the next: unhealthy gasoline strain, unhealthy combustion air, and poor situation of the warmth exchanger. A really fundamental, newbie’s information to combustion evaluation will typically concentrate on three large measurements – oxygen, manifold strain, and carbon monoxide. A extra intermediate strategy will even have a look at extra air, carbon dioxide, stack temperature, and carbon monoxide air-free. Realizing what these measurements imply is essential to performing a correct combustion evaluation.

OXYGEN (%O2) and Extra Air (%EA)

Typical O2 readings: 5-12% O2

Dangerous O2 readings: 0% O2, 20% O2

Typical EA readings: 10-150%

Dangerous EA readings: 0%, >150%

One visible cue of poor combustion is the presence of soot, a black powdery substance, and byproduct of an incomplete combustion of a hydrocarbon. Not solely is soot a nuisance to scrub, however it might probably additionally trigger issues if it clogs burners and/or prevents the move of combustion air. Generally that is known as a “fuel-rich” combustion as a result of there’s an excessive amount of gasoline for the quantity of oxygen current. Whereas alternative of the unit or a radical cleansing might be a right away repair, if the unique supply of the combustion air drawback shouldn’t be addressed, the identical drawback will occur once more. One factor to test for, particularly in conditions the place a furnace or scorching water heater is in a closet, is that if the closet door has louvers. There should be a way that air enters the area.

Combustion air is usually divided into three classes: major, secondary, and extra. Main air is definitely managed by the gasoline strain because of the venturi impact pulling air in as gasoline forces its manner by very small orifices, instantly mixing with this major air and controlling the quantity of gasoline that may be burned. Secondary air is what surrounds the burners and it permits the given quantity of gasoline to totally burn, finishing the combustion course of. Extra air, subsequently, is the leftover air after full combustion. A certain quantity of extra air acts as a reassurance that the furnace goes by full combustion with little or no dangerous byproducts. An excessive amount of extra air can also be known as “air-rich” combustion. Whereas too little air causes soot, an excessive amount of air causes wasted warmth as the surplus oxygen will soak up the warmth and ship it out the exhaust stack.

Usually when sending in a plugged warmth exchanger for a guaranty declare, the producer will ask for the unit’s extra air measurement as this can be a certain signal of the secondary being plugged.

Watching the O2 and extra air readings because the blower activates generally is a fast and straightforward method to inform if the warmth exchanger is cracked.

Gasoline Manifold Strain (Inches W.C.)

Typical readings: Examine the producer knowledge plate, sometimes 3.2-3.8 inches

Dangerous readings: Very low or very excessive, being attentive to which stage the valve is in

As a result of good combustion is the results of the proper combination of air and gasoline, normally the best factor to test and alter is the gasoline strain, measured in inches of water column (WC), with a manometer (some combustion analyzers have the flexibility to learn gasoline strain). Although gasoline strain ought to all the time be dialed in when the furnace is commissioned, generally it doesn’t harm to test. The beneficial strategy of adjusting gasoline manifold strain is to clock the gasoline meter, particularly with high-efficiency furnaces, to test the common warmth content material of the gasoline provided. If the furnace shouldn’t be tuned in with the precise BTU enter, the furnace is not going to run as effectively because it may very well be.

Generally, the gasoline valve within the furnace shouldn’t be commissioned accurately, and a standard visible cue may be the furnace tripping excessive limits.

Carbon Dioxide (%CO2) and Stack Temperature

Typical CO2 readings: 5-10%

Dangerous CO2 readings: 12%

Typical stack temperature: 80-120F for 90% AFUE, as much as 400F for 80% AFUE

Dangerous stack temperature: >120F for 90% AFUE, <270F for 80% AFUE

As a result of combustion converts carbon into carbon dioxide based mostly instantly on the quantity of combustion air, most digital combustion analyzers don’t actually measure CO2 – moderately, it’s calculated based mostly on measured values. That is normally set to show if there’s simply sufficient O2 (in different phrases, 0% O2 within the flue). CO2 is at its theoretical most of about 11.8%.

Stack temperature, the temperature of the flue gasoline, is a key indicator of efficiency because it measures how a lot warmth is misplaced within the flue. Excessive-efficiency furnaces have cooler stack temperatures as a result of they put that additional warmth power into the house.

Carbon Monoxide (PPM CO) and CO Air-Free (CO(0))

Typical CO measurement: 0-80 ppm

Dangerous CO measurement: >200 ppm CO or >400 ppm CO(0)

Carbon monoxide is an odorless, colorless gasoline the place publicity to as little as 10 ppm could cause complications, fatigue, and dying in lower than two hours at 800 ppm. Many shoppers have carbon monoxide detectors of their properties. Nevertheless, as a result of the standard CO sensor is not going to alarm at ranges beneath 30 ppm, low-level CO detectors coupled with common upkeep is the perfect safety towards carbon monoxide poisoning.

Combustion analyzers sometimes give two readings for carbon monoxide: CO and CO air-free. As a result of extra air dilutes the CO within the flue stack, the focus of CO might not look too unhealthy. Due to this fact, the analyzer makes use of a components to learn out a CO measurement “air-free.” Due to this fact, technicians will discover that the CO(0) is all the time increased than the CO measurement and considerably increased if the EA is excessive. There are requirements for each, so usually if you find yourself speaking outcomes with producers, they could ask for the CO(0) measurement as properly.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Supply hyperlink

Add Comment