As the HVAC industry transitions toward lower-GWP refrigerants, many contractors and technicians are encountering a frustrating reality on job sites: R-454B, the new go-to A2L replacement for R-410A in many systems, is in short supply — and expensive. Faced with installation delays or pressure from customers to get systems up and running, some may feel tempted to “top off” or replace the mildly flammable R-454B with other refrigerants such as R-410A or R-32, just to get the job done.

The ongoing shortage has even led some technicians to consider mixing their own R-454B in the field, but this is both illegal and unsafe. Chemours and Honeywell hold the patents for R-454B, so producing it without a license constitutes patent infringement. R-454B is also a precise blend of 68.9% R-32 and 31.1% R-1234yf, making it highly sensitive to improper ratios. Incorrect mixing can alter its pressure and glide characteristics, leading to system failure and EPA violations. Field-mixed refrigerants are also not certified or tested and will definitely void equipment warranties.

Even when done with good intentions, mixing refrigerants is a dangerous gamble with potentially serious consequences — not just for equipment reliability, safety, and regulatory compliance, but also for a contractor’s reputation.

Manufacturer Concerns

The majority of HVAC manufacturers in the U.S. selected R-454B for their new ducted comfort cooling systems, with the exception of Daikin, Goodman, and Amana — along with several ductless manufacturers — which opted for R-32. Daikin recently expressed concern about refrigerant mixing in a notice issued to customers, which emphasized that the DOE/EPA regulations for servicing equipment with approved refrigerants are “quite stringent and thoroughly enforced.”

The notice went on to state that, “Using R-32 in an R-454B unit is not only against manufacturers’ recommendations, due to differences in their chemical compositions and operating characteristics, it is also illegal. Unless an alternative has been approved by EPA’s Significant New Alternatives Policy (SNAP) program (and the necessary system modifications have been made), each HVAC unit is designed for a specific refrigerant, and using a different refrigerant can lead to malfunctions or damages.”

Trane also recently sent out a notice to customers, stating, “HVAC units must be installed and serviced with the refrigerant indicated on the unit nameplate, according to the UL safety standard (60335-2-40) and the [EPA] SNAP 23 rule. R-454B and R-32 are not interchangeable. By ensuring R-454B is used only in products designed for it, dealers can avoid potential issues during inspections and maintain compliance with legal standards.”

In a statement to The ACHR NEWS, a spokesperson from Trane Technologies’ residential HVAC business added, “Technicians should install and service systems as determined by their safety and operating instructions. Adhering to the standards helps ensure the warranty can remain valid, the system runs as designed, and safety is prioritized. Based on our customers’ needs during this challenging time, we’ve prioritized making extra factory refrigerant charge available in select units. This helps alleviate the need for technicians to add additional refrigerant at the time of installation.”

There is no question that transitioning to mildly flammable refrigerants presents new challenges, especially for technicians who must now manage both legacy R-410A systems and newer A2L equipment. That is why HVAC technicians must be equipped with the right knowledge, tools, and resources to handle multiple refrigerants simultaneously, said Brad Boggess, director of materials engineering at Copeland.

“As a rule, it’s important to remember that fluids and components are not interchangeable — both among new and legacy equipment and specific A2L refrigerant blends.”

With this in mind, Boggess advises contractors to follow these guidelines:

- Do not charge an R-410A system with an A2L refrigerant (or vice versa);

- Do not charge an R-454B system with R-32 refrigerant (i.e., two different A2Ls);

- R-410A compressors, lubricants, or components may be incompatible in an A2L-optimized system (and vice versa); and

- In A2L systems requiring leak detection, devices and/or sensors must be optimized to detect a specific A2L refrigerant (i.e., R-454B or R-32).

Consequences

Topping off an R-454B system with either R-32 or R-410A is never a good idea, said Jason Obrzut, director of industry standards and relations at ESCO Institute. Not only is it an EPA violation, but mixing refrigerants can also lead to system failure.

“R-454B has a glide, and if it’s not mixed and tested and chemically analyzed, you don’t know what your glide is, so you don’t know if you’re charging properly or not,” he said. “And a lot of these systems are heat pumps, so while a problem may not spring up during the cooling season, when the equipment shifts over to heating season, there’s going to be some serious problems.”

Consider that R-454A, R-454B, and R-454C are all different blends of R-32 and R-1234yf, and each has its own glide, ranging from ~1.5°F for R-454B to ~8°F for R-454A. Introducing straight R-32 into an R-454B system will alter the blend’s composition and increase the glide, potentially harming system performance and reliability, as well as reducing latent heat removal.

“How much will that glide increase? You don’t know,” said Obrzut. “So after installation, all the temperatures are fine, pressures may seem fine, but you don’t really know what latent and sensible heat you’re removing, because you don’t know what the glide is on the refrigerant you just created. The glide is definitely going to go up to an unpredictable number.”

Too much R-32 in an R-454B system could then damage components — especially the compressor — due to R-32’s higher discharge temperature and its use of a different oil.

“Let’s say you have a 50-foot line set, and the system is precharged for 15 feet,” said Obrzut. “You’re putting a lot of R-32 in there, and you’re going to have a way higher discharge temperature. This will cause the oil to break down, and you’re going to overheat the compressor. If it’s an inverter system with thermistors, it’s going to scale it down, and you’re going to lose capacity to try and lower the discharge temperature, especially when heating.”

Because R-454B was designed to closely match R-410A, some contractors might think it is okay to remove R-454B from a system and recharge it with R-410A, if there isn’t enough R-454B to complete the job. This, too, is an EPA violation, as well as a very bad idea.

“First of all, if you pull out the R-454B and replace it with R-410A, you’re going to void the warranty if the manufacturer finds out,” said Obrzut. “Second, you’re creating a scenario where someone who works on that unit next doesn’t even know what’s in it, and they could end up mixing in something else. Because the unit is labeled R-454B, someone might try and put R-454B on top of the R-410A already in the system, which could cause problems. R-410A is R-32 and R-125, and R-454B is R-32 and R-1234yf, so now you’ve got three different refrigerants in there.”

The final result is just soup, said Obrzut, which is exactly what has happened with R-22 equipment. “When I work on an R-22 unit, I use a dirty old set of gauges, because I don’t know what’s in there. There may be a mixture of six different refrigerants, or it might be one refrigerant. If we do that with R-410A, R-454B, and R-32, we’re going to get soup, but the problem there is that two of those refrigerants are A2Ls and one’s an A1.”

Solutions

Refrigerant manufacturers have been relatively quiet about how long the R-454B shortage will last, but during Chemours’ first-quarter earnings call, President and CEO Denise Dignam said they expect the issue to be resolved soon. She noted that stronger-than-expected demand is putting pressure on various parts of the supply chain, especially the availability of cylinders used to ship and transport the R-454B blend for stationary aftermarket sales.

“While we understand that there is tightness in the supply of cylinders used, we are increasing our line fill capacity in order to quickly fill cylinders as they arrive from our sources,” she said. “We believe the situation will correct itself quickly and will not be a long-term issue for Chemours’ ability to support the R-454B market transition.”

Others seem to think the shortage could last a little longer. Several equipment manufacturers don’t expect to see improvement until the beginning of the third quarter, while some predict the shortage could extend into next year.

“I don’t think we’re going to hit that equilibrium until the fall, which means this summer is going to be rough,” said Obrzut.

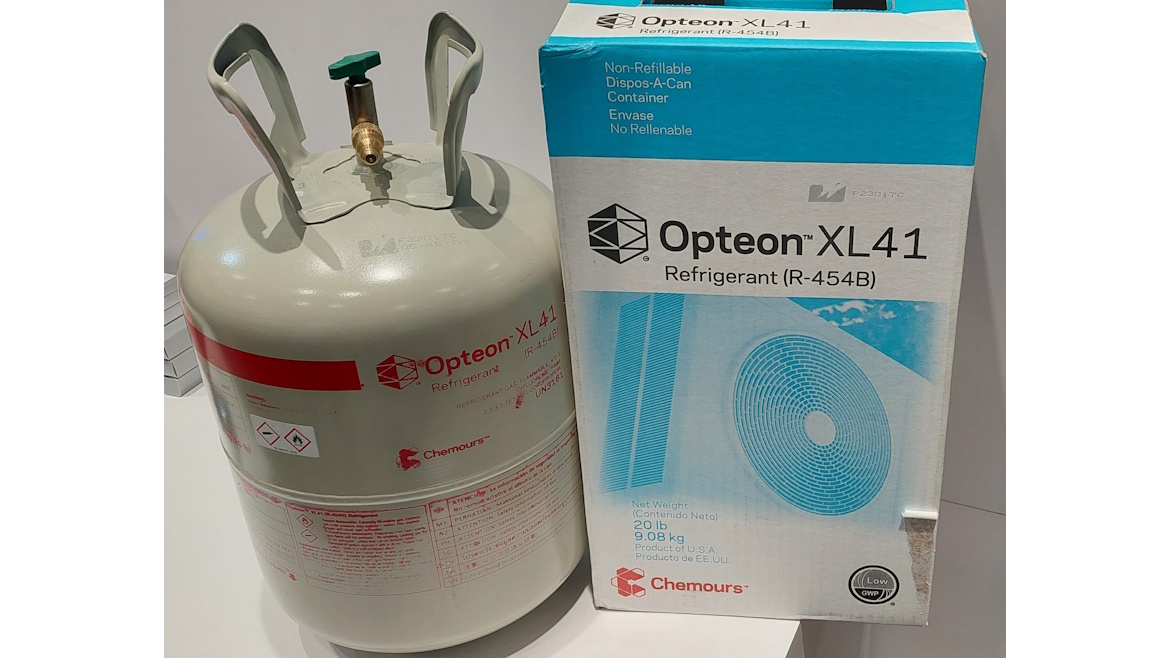

However, he noted that there are several ways contractors can effectively manage the shortage. First, while the 20-lb cylinders of R-454B may be in short supply, the larger 90- or 100-pound cylinders appear to be readily available.

“They are more money and they’re refillable, so they require a deposit, and you’ve got to return them, but that is an option,” he said. “It’s a heavier tank to run around with, but you’ll still be able to do work and be in compliance.”

Second, diversify your equipment offering and be prepared to use some R-32 equipment, said Obrzut. And third, expand your distribution network, because even though you can’t buy R-454B at one supply house, you may be able to find it at a different one.

“This problem is going to last awhile,” he said. “While demand for R-454B will taper off in the Midwest in August and September, there is going to be demand in the southern part of the country, where it’s still really hot and really humid. And states like Texas, Florida, and Arizona have heat pumps, so even if the temperature drops, they’re still using refrigerant in November, December, and January for heating.”

While the R-454B shortage is creating real challenges in the field, contractors who stay flexible and proactive can continue to operate effectively, remain in compliance, and avoid resorting to unsafe or illegal practices.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link