Refrigerant Pump Down Defined

By: Gary McCreadie

Pumping down a refrigerant circuit is a good way to keep away from liquid migration again to the compressor on the off-cycle. Refrigerant will naturally equalize and transfer to the part of the system with the bottom ambient temperature. If that part occurs to be wherever on the low aspect of the system, we might probably have a liquid slug on begin up.

What’s a pump down anyway? A system pump down makes use of a solenoid valve within the liquid line, when the system set-point temperature has been happy, the solenoid valve will shut. The compressor will proceed to pump refrigerant into the condenser and/or receiver, drawing it from the low aspect of the system. The condenser or receiver or a mixture of each should be designed to carry the whole cost of the system. The compressor operation will cut-out as soon as the pre-determined set level of the low-pressure change, or LPS for brief, has been reached. The LPS cut-out setting will likely be straight associated to the software and/or refrigerant getting used. In reverse, on a name for cooling, the solenoid valve will open. The refrigerant will journey into the low aspect of the system because of the strain distinction between the two sides. As soon as the pre-determined LPS cut-in set-point has been reached, the compressor will begin and resume regular operation. Once more, the cut-in setting is straight associated to the applying and/or refrigerant getting used. Normally, this order of operations is computerized and wired as such to carry out this job. A handbook pump down will also be carried out on many programs if a solenoid valve is not current by manually closing the King valve (valve on the receiver outlet) for instance. Earlier than trying this technique, be certain that you totally perceive this process, as harm to system parts can happen if carried out incorrectly.

Recycling Pump Down

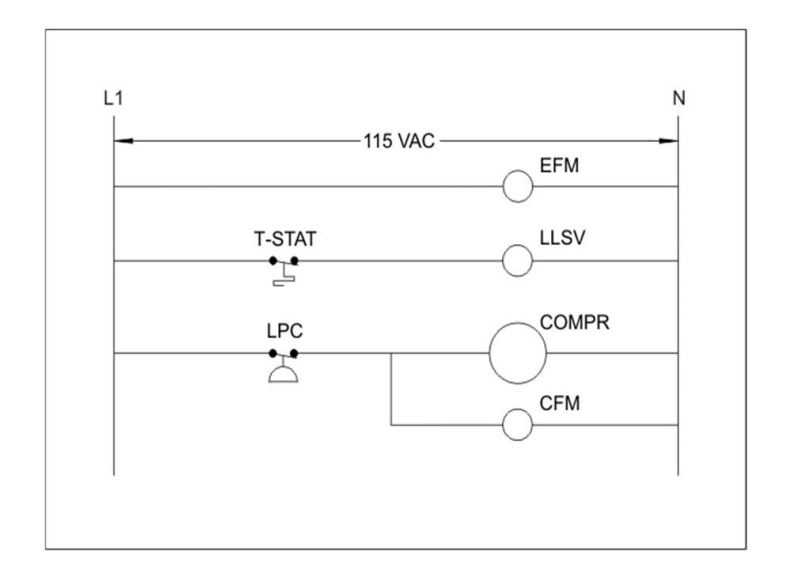

There are two kinds of pump down circuits, electrically talking. That is in regard to the best way they’re wired to function. The primary is the “Recycling Pump Down” circuit. The strategy of pump down continues to be the identical, utilizing a LPS and solenoid valve. Nonetheless, if on the off cycle refrigerant is ready to creep by internally leaking solenoid valves or compressor valve plates this may enhance the low aspect strain closing the LPS. On this case, the compressor will begin and carry out a pump down throughout the off cycle to be certain that liquid migration will not be happening. An obstacle with this fashion of pump down is the potential for elevated compressor begins over time. The clear benefit is that your compressor won’t ever begin loaded with liquid within the sump.

Diagram courtesy of refrigerationbasics.com

Non-Recycling Pump Down

The second sort is the “Non-Recycling Pump Down” circuit. Once more, the strategy of pump down continues to be the identical. On this case, if there may be any refrigerant migration throughout the off-cycle the compressor won’t begin and carry out a pump down. Discover the usually open change (Maintain) that won’t permit the compressor to restart on the off cycle. The system thermostat should be calling (within the closed place) to ensure that the compressor to start working. The LPS will nonetheless shut if valves are internally leaking by, however the compressor won’t begin till there’s a name for cooling. A direct drawback of this technique is sort of apparent, the compressor might begin with liquid refrigerant current within the sump. Alternatively, there may be the potential for much less complete compressor begins.

Diagram courtesy of refrigerationbasics.com

Most programs that I’ve labored on by way of the years have utilized “Recycling Pump Down”. I discover this to be a superior technique to guard the system from catastrophic failure. A number of you may say, “why not substitute the internally leaking components?” On massive programs this generally is a expensive enterprise, particularly if there are a number of components in query. In an ideal world, all components can be sealed tight and the worry of inner leak points wouldn’t be an element. The “Recycling Pump Down” is designed for the inevitable that all of us expertise day by day, flaws upon flaws from system to system. One advice I’d make, is to make use of an adjustable low-pressure change, this manner you might be in management and may make changes to the pump down cut-in and cut-out as crucial.

Gary McCreadie

Comply with HVAC Know It All on Instagram, Fb, YouTube and LinkedIn and LISTEN to the HVAC Know It All Podcast

Save 8% on purchases at TruTech Instruments with code knowitall (excluding Fluke and Flir merchandise)

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Supply hyperlink

Add Comment