Key Takeaways

- Fewer Failure Points: Scroll compressors have approximately five times fewer moving parts than reciprocating compressors of equal capacity, resulting in greater reliability and lower maintenance requirements

- Superior Efficiency: High volumetric efficiency means scrolls use compression space more effectively than reciprocating types, with minimal “lost” compression or gas re-expansion

- Hermetic Construction: Welded-shut design protects internal components and eliminates serviceability concerns when compressors are properly selected and operated

- Parallel Staging for Load Matching: Single-speed scrolls can be joined in parallel compression arrangements to provide 50% and 100% capacity control, making them suitable for varying load conditions

- Residential-Friendly Operation: Low vibration and noise levels with vertically-rotating crankshafts make scroll compressors ideal for installations near occupied spaces

Introduction to Scroll Compressor Technology

The Scroll Compressor is one of the most popular compressors in the modern HVAC/R Industry. There are a few different types, and this article will focus on Single-Speed Scroll Compressors. This will be followed by articles on Variable Speed Scrolls and Two-Stage Scrolls. This first article will also act as an introduction to Scroll Compressors and their basic operation. The application and specific details for Single-Speed models will also be covered in this writing.

Hermetic Construction: Built for Reliability

Scroll Compressors are of the Hermetic construction type. Characterized by their welded shut container, which leaves the internal components unserviceable. This, however, matches the design profile of Scrolls, as this area should never need servicing if the compressor is selected and operated properly. Images in this article are courtesy of Danfoss.

Scroll compressors can deliver 15-20 years of reliable service, but eventually every system reaches end of life. Arriving at service calls knowing equipment age and previous repair history changes the conversation from reactive repairs to proactive planning. Property.com’s ‘Know Before You Go‘ tool provides this intelligence automatically, helping you spot replacement opportunities before emergency failures occur.

Understanding Positive Displacement Compression

The Scroll Compressor is a Positive Displacement Compressor: The Refrigerant is compressed by reducing the area within which the gas can “exist” as the Scroll rotates. The Scroll Compressor is a versatile option, making it popular in Residential, Commercial, and Industrial Refrigeration and AC applications.

Key Advantages of Scroll Compressors Over Other Types

Scroll Compressors have a simple exterior shape: they are long from top to bottom as the Crankshaft turns vertically within. They can be a bit awkward to move around (there are special tools for this), but this shape gives them a small frame footprint relative to their capacity, opposed to other Compressor Types (Reciprocating, Scroll, Screw, and Centrifugal). Scrolls have replaced Reciprocating Compressor models often in the market, and we will see some comparison of the two models below.

Fewer Moving Parts Mean Greater Reliability

The internal design of a Scroll Compressor is quite intuitive, however simple. There are not many moving parts compared to other Compressor Types, and this is an advantage. Fewer moving parts allow for fewer failure points. For comparison, a Reciprocating Compressor of the same capacity will have around five times more moving parts than a Scroll.

Superior Volumetric Efficiency

Scrolls offer a high Volumetric Efficiency (or VE), which makes them very energy efficient. This means that within the internal volume in the Scroll’s “Compression Area”, most of this space is used to compress the refrigerant effectively. This equates to not much “lost” Compression or re-expansion of gas and is superior in this respect to Reciprocating Compressors.

Note: Reciprocating types have lower VE due to Clearance Volume above their pistons at Top-Dead Centre.

Low Maintenance Requirements

Scrolls also have low maintenance requirements, as referenced in the opening. This is a reason why the Hermetic construction is appropriate for a Scroll. The Mechanical Maintenance procedure for Scrolls required would be performing an Oil Change, but this is done at the lowest frequency in all Compressor types. For industrial applications, proper oil management is critical to system longevity. Learn more about avoiding premature compressor failure through correct brazing, evacuation, and charging procedures.

Note: Scrolls only come in Hermetic models, while other Compressors may be Hermetic, Semi-Hermetic, or Open-Type (external Motor).

Suction-Cooled Motor Design

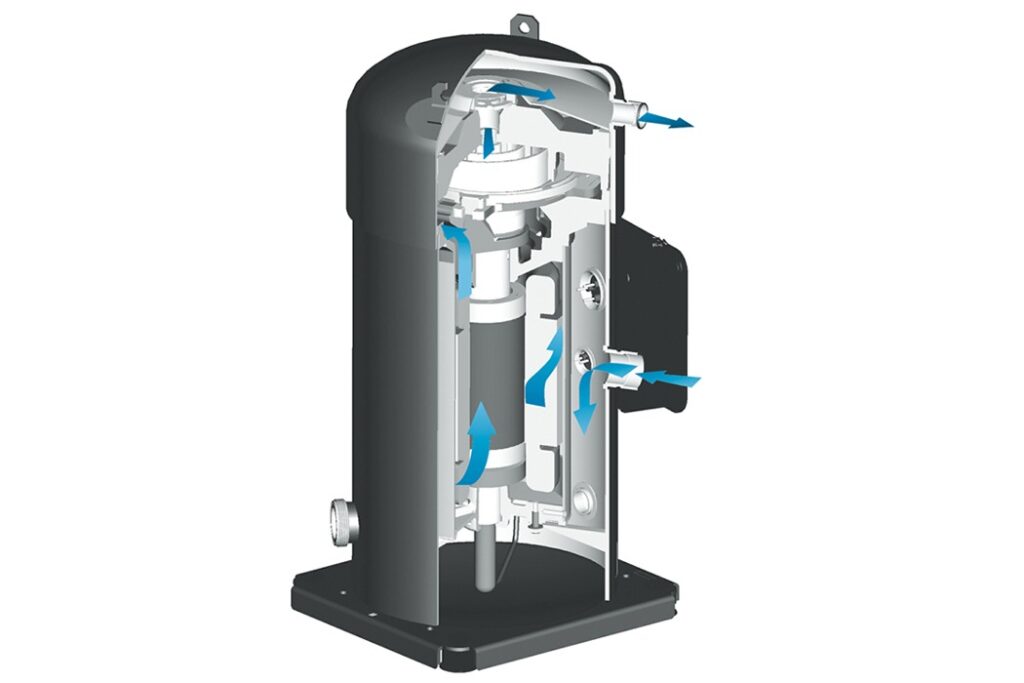

As usual in a Hermetic design, the Scroll Compressor’s Electric Motor resides within the Compressor shell. There are different arrangements, but it is common for the Electric Motor to be “Suction Cooled”. This utilizes the return Suction Gas to have its internal path within the Compressor to help cool the Motor before it is again compressed. The wiring connections for the Motor are located on its exterior inside a junction box (the “Black Box” shown in this article’s images).

Reduced Vibration and Noise Levels

The Vibration and Noise Levels produced by Scroll Compressors are on the low end, compared to other Compressor types. This characteristic makes them appropriate for Residential applications where the Compressor’s Condensing Unit may be installed near an occupied area. This quiet operation makes scroll compressors ideal for ductless mini-split systems, which acheive optimal performance through careful design and placement.

Note: Though it is not as great a factor as in other Compressor types, Vibration is still an important installation consideration for scrolls. Taking note that the crankshaft vibration pattern is unique in a Scroll when compared to other Compressors, as the Scroll’s crankshaft is rotating vertically opposed to horizontally.

How Scroll Compressors Work: The Compression Process

This video by Danfoss shows a great animation of how Scroll Compressors work. The Orbiting Scroll is driven by the crankshaft, and through rotation interacts with the Stationary Scroll to displace refrigerant and create Compression. As mentioned previously, the Volumetric Efficiency of Scroll Compression is great, making for efficient compression.

Refrigerant Flow Path

In the second image above, the flow of Suction gas is shown entering the side of the compressor during operation. Its path turns and travels downward, before turning again upwards to be received by the Scrolls to be compressed. Once compressed, the Discharge gas leaves the compressor on the outlet at the top.

The image immediately above shows some additional Danfoss improvements and features in their 120H1190 Model. Without detailing these points, the image provides another cutaway drawing for viewing on internal Scroll components.

Capacity Control Through Parallel Compression

Single-Speed Scrolls are simply on/off and are either running at 0% or 100% Capacity. For Capacity Control, these compressors can be joined in Parallel as shown in the image below.

Staging Compressors for Load Matching

Parallel Compression allows increased Capacity Control by joining the two Compressors’ Suction and Discharge Lines together. The First Stage Compressor will run to meet 50% required capacity, and the Second Stage Compressor will additionally run to meet 100% of the required capacity. This allows the Compressors to have more ability to maintain System Load, especially if it is varying.

Note: In the article’s final image, the copper tube running horizontally is a Common Oil Line. This allows oil transfer between the two Compressors’ Crankcases. This ensures that if only one Compressor is running, it has sufficient oil for lubrication. Notice the Compressor Oil Sight Glass shown in all images.

Liquid Injection for High-Demand Operation

Note: Liquid Injection is a method utilized in Single-Speed Scrolls. When compressors are operating near their Maximum Capacity, small amounts of Liquid Refrigerant are injected into the Compressor during the compression process. This reduces Refrigerant Superheat and internal temperature of the Compressor to allow it to meet high demand. Protection from liquid refrigerant in the suction line can be enhanced with suction line accumulators. Proper refrigerant charging procedures ensure optimal compressor operation and prevent liquid slugging issues.

Summary: Why Single-Speed Scrolls Remain Popular

A common and simple arrangement for Scroll Compressors is the Single-Speed model. The simplicity and relatively low cost compared to other models make this a popular choice in Domestic, Commercial, and Industrial Refrigeration and AC Applications.

Practical Benefits for Varying Load Conditions

The ability to join the Compressors in parallel makes the Single-Speed a good candidate for meeting varying loads while utilizing Compressor Staging to operate one, two, or multiple compressors to react to load.

Efficiency and Versatility Combined

Scroll Compressors have a low requirement for maintenance, and the Single-Speed model is the easiest to understand. With their efficient compression design and ability to utilize auxiliary controls and accessories allows the Single-Speed Scroll Compressor to function well in many applications. For more complex capacity modulation requirements, technicians can explore advanced options like variable-speed compressors that offer even greater efficiency and control.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link