When replacing components on a refrigeration system, you may also need to replace some of the wiring. This could be necessary because the original wiring is old and frayed, or because the new component requires a slightly different wiring configuration.

When doing so, it is important to select the correct wire gauge for the required amperage and decide whether to use solid or stranded wire. In most cases, the best practice is to use the same type of wire that was originally installed with the component you are replacing.

However, if you don’t have the same type on hand, you need to decide if it’s acceptable to substitute one for the other. For example, suppose you’re replacing a temperature controller on a reach-in cooler. The original wiring is 14-gauge stranded, but you only have 14-gauge solid wire available. Can you use it? Understanding the differences between the two types will help you make the right choice.

Solid wire is made from a single piece of conductor. It is typically used in low-flex or stationary applications — areas not subject to vibration from components such as fan motors or compressors. Because it is rigid, solid wire can crack or break over time if it is exposed to constant movement or vibration.

Solid wire is best suited for building electrical systems, such as the power feed leading to a refrigeration unit. Solid wire is easier to push through conduit, offers slightly lower electrical resistance, and is ideal for longer electrical runs where flexibility is not a concern.

Stranded wire consists of multiple small wires twisted together, giving it more flexibility and resistance to vibration. This makes it ideal for use inside refrigeration systems, where components like fans, compressors, and relays generate continuous movement.

Because it is more flexible, stranded wire is also easier to run between components in tight or irregular spaces. That is why most internal wiring in refrigeration systems uses stranded wire rather than solid.

Looking for quick answers on air conditioning, heating and refrigeration topics?

Try Ask ACHR NEWS, our new smart AI search tool.

Ask ACHR NEWS

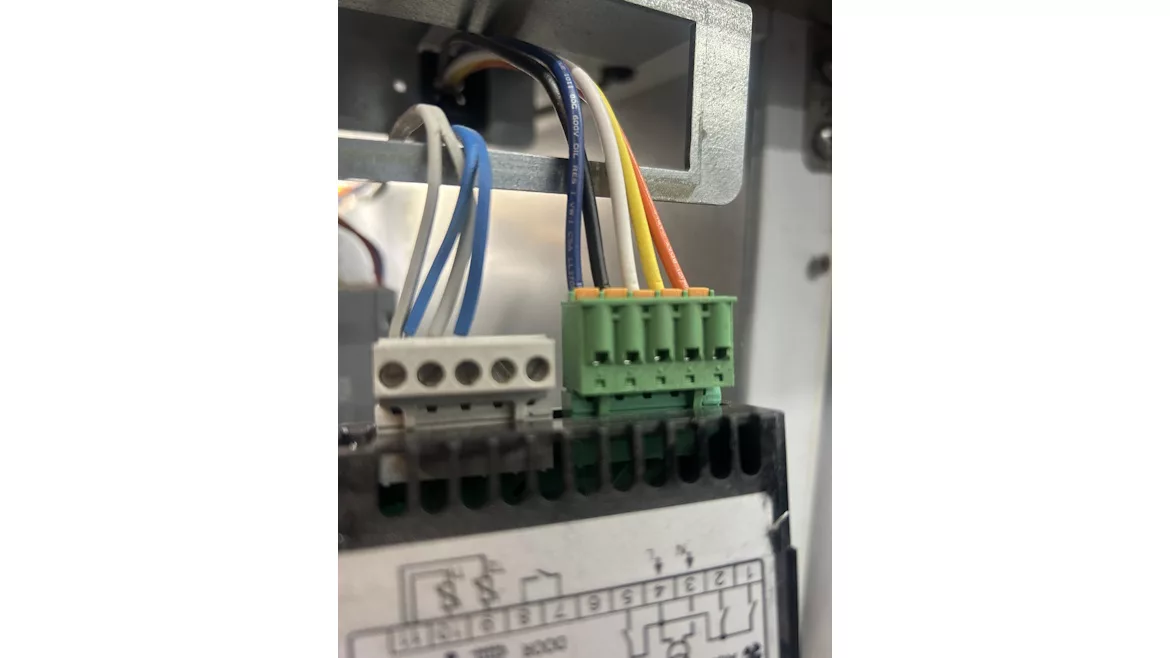

When terminating stranded wire — whether on a contactor, relay, temperature controller, or terminal block — the goal is to create a secure, low-resistance electrical and mechanical connection that resists vibration and loosening over time.

Attaching a terminal connector to the end of stranded wire helps ensure a tight, reliable connection. A ferrule is an excellent option when securing stranded wire to a clamp-type terminal. The ferrule compresses the strands into a single solid unit, preventing stray strands from spreading or breaking. For screw or stud connections, ring, spade, or fork terminals are good options.

When stripping stranded wire to attach to a terminal, avoid removing too much insulation. Typically, ¼-inch of exposed wire is sufficient. Stripping too much can leave bare wire exposed beyond the terminal, increasing the risk of shorts or corrosion.

Before completing the repair, double-check all connections to make sure they are tight and secure. Loose connections are a common cause of intermittent faults and warranty callbacks. This is especially important when the wiring is attached to the component before it is mounted to the cabinet. It is not uncommon for a loose connection to go unnoticed until power is restored to the system.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link