Step by Step Refrigerant Restoration Course of

I typically see new techs asking the right way to get well or skilled techs asking the right way to get well sooner, so let’s check out each. If trying to join with a robust tradition of HVAC technicians, take a look at the subscription-based HVAC Know It All app.

This all originated from some private trial and error when an air-con producer I labored for had a recall, a lacking Schrader core on the receiver service valve (king valve) of all issues. This was a doable catastrophe for an unsuspecting tech. Take away the cap anticipating a valve core, and properly… Not enjoyable. So it was time to put in a single valve core in 50 operational items in crucial areas, every holding between 50 and 100 kilos of R-410A.

I had a fairly repeatable scenario on my fingers, and I had the chance to attempt all kinds of issues: restoration cylinder dimension, hose dimension, hose sort, and many others. I’ll cowl all this on the backside of this text, however we’ve received to begin with the fundamentals!

How do we get well?

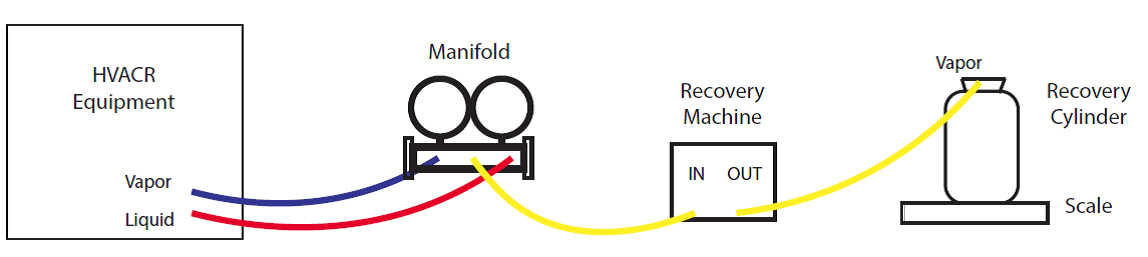

There are two typical strategies, direct restoration and push/pull. You must at all times familiarize your self with the tools you might be working with, however I’ve included a easy diagram of the right way to join the required tools and a “step-by-step” information for the newer techs.

Direct Restoration

That is our typical restoration methodology, which will probably be how each restoration job will end.

1. Begin with all valves closed (restoration cylinder, restoration machine, manifold, hoses.)

2. Setup hoses as proven within the diagram.

3. ZERO/TARE the refrigerant scale.

4. Open hose valves, core removing device valves or service valves.

1. —The beneath steps will fluctuate with your restoration machine—

5. Set the refrigerant restoration machine to get well.

6. Open the excessive facet of the manifold for liquid restoration.

7. PURGE THE HOSES OF AIR, loosen and unseat the hose linked to the restoration tank till the refrigerant is current, after which retighten.

8. Absolutely open the vapor valve on the restoration cylinder.

9. Activate the restoration machine.

2. —The beneath steps ought to be normal for most restoration machines—

10. The manifold excessive facet valve could have to be adjusted to throttle refrigerant move into the refrigerant restoration machine to keep away from liquid slugging.

11. When the liquid restoration is full, totally open each the excessive facet and low facet manifold valves.

12. Many restoration machines will flip off as soon as the system reaches a vacuum.

13. PURGE THE RECOVERY MACHINE – this one could be fairly particular – so verify your handbook in the event you’re uncertain.

14. Shut all valves and restoration is full!

Push/Pull

This will probably be your sooner possibility if the system has 15 or extra kilos of refrigerant. The extra refrigerant the system holds, the extra time you’ll save. Tip: Utilizing an inline sight glass throughout push-pull restoration will permit you to visually decide when the liquid move has stopped.

1. Begin with all valves closed (restoration cylinder, restoration machine, manifold, hoses.)

2. Setup hoses as proven within the diagram.

3. ZERO/TARE the refrigerant scale.

4. Set the restoration machine to get well.

5. PURGE THE HOSES OF AIR (that is executed barely in a different way than in direct restoration.)

a. Open the liquid line service valve or core device after which loosen and unseat the hose linked to the liquid port on the restoration tank till the refrigerant is current after which retighten.

b. Open the vapor line service valve or core device after which loosen and unseat the hose linked to the vapor port on the restoration tank till the refrigerant is current after which retighten.

6. Activate the restoration machine.

7. When liquid restoration is full, swap to Direct Vapor Restoration.

Now, let’s pace it up…

Valve Core Removing Instruments

• In case you had been solely going to alter one factor – that is it! In case you’re caught pulling via valve cores, get two of those. They’ll even assist pace up your evacuation.

Restoration Cylinder

• Be certain the cylinder is clear and has been evacuated to 500 microns or much less. And NEVER fill past 80%. This enables for the growth of the refrigerant.

• If it’s sensible, use a bigger cylinder; this can make the restoration go faster.

Hoses

• Keep away from hoses with “anti-blowback” or “low loss” model fittings.

• Commonplace hoses are ¼” – utilizing bigger diameter hoses will get you quicker restoration. They’re typically marketed as “heavy responsibility,” “charging,” or “vacuum” hoses.

• Use hoses which can be as brief as doable.

Temperature

• Settle down the restoration cylinder– this can drop the stress of the restoration cylinder.

• With many restoration machines, you should use the fan to attract air over the restoration tank.

• Water will work even higher, however you’ll want water move.

• Settle down the refrigerant! This one tends to be your greatest guess in the event you’re coping with massive volumes of refrigerant – there are warmth exchangers out there for only for this objective.

Filter It!

• In case you suspect the system refrigerant to be soiled, use an inline filter drier on the inlet to the restoration machine.

With strategies starting from nothing new required to a complete new rig for restoration, you’ve received selections to hurry up your restoration in nearly all purposes. Give a few of these a try to see how they be just right for you.

Dan Reggi

Humber School Professor

Observe HVAC Know It All on Instagram, Fb, YouTube and LinkedIn and LISTEN to the HVAC Know It All Podcast

Save 8% on purchases at TruTech Instruments with code knowitall (excluding Fluke and Flir merchandise)

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Supply hyperlink

Add Comment