✕

The results of a new survey conducted for The ACHR NEWS by myCLEARopinion once again proved a very basic truth when it comes to homeowners — they have a strong desire to save money.

According to the data, high-efficiency HVAC equipment is extremely favorable amongst the homeowners survey, who nearly unanimously viewed it as essential: 34% reported it to be “extremely important,” while 43% said very important, 19% important, 4% not very important and less than 1% saying it’s not important at all.

To help contractors capitalize on this strong sentiment from homeowners, ACHR NEWS reached out to several industry experts, who emphasize the importance of staying knowledgeable about specific tax credits, ensuring businesses have the capability to meet demand, showcase the savings, and making sure technicians are apprised of the installation process specifics.

What Homeowners Want – And How Contractors Can Deliver

The study took a deeper dive into why homeowners into what homeowners viewed as the key advantages of high-efficiency equipment. Unsurprisingly, the top response, chosen by 92%, said it was the lower monthly bills. Other perceived advantages were tax credits/rebates (64%), improved indoor air quality (54%), better comfort (53%), reduced impact on the environment (46%), and less noise (43%).

With monthly savings being a huge selling point, there are several ways for contractors to capitalize on that aspect and deliver homeowners with data specific to their situation. The best place to start is to ensure the system is properly sized.

“The simple and broad answer to this question is: start with a load calculation,” Thomas Hoffmaster, Contractor Success Manager at Rewiring America, said. “No contractor should be installing a high-efficiency heat pump without first doing a load calculation, regardless of whether they have a current heat pump or a/c system.”

When a homeowner is contemplating dropping the money on a state-of-the-art system, they naturally expect high-end results for both energy savings and comfort. This makes the load calculation not only important for proper sizing of the equipment but also for customizing sales pitches with accurate operational savings estimates, Hoffmaster said. A great place to really get a better grasp is in Section 11 of ACCA’s Manual RS, titled “Energy and Operating Cost Calculations.”

“While I have encountered contractors who will give approximate savings in percentages as a sales pitch, I do not recommend that method,” Hoffmaster said. “In the Manual RS, section 11-2 states in its heading ‘The Calculations Should be Site-Specific,’ meaning that the load calculation for that home along with the utility costs and weather associated with the specific area.”

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!

David Rames, senior product manager at Midea, said contractors can also leverage tools like the Energy Star savings calculator and other financing models to present a clear, personalized cost-benefit analysis to homeowners.

“By comparing the energy costs of their existing system with a high-efficiency upgrade, contractors can demonstrate long-term savings in monthly bills,” Rames said. “For example, tools that estimate savings based on regional energy rates and climate conditions can make the value of high-efficiency equipment more tangible. Pairing these calculations with information on local and federal rebates and tax credits can further lower the perceived cost barrier, helping homeowners see the financial and environmental benefits.”

Lance Ellison, operations manager at Abacus Plumbing, Air Conditioning & Electrical in Houston, Texas, said they utilize a document called the “net investment cost savings calculator.”

It calculates the cost of ownership of a homeowner’s current HVAC system — including breakdowns and extra energy consumption — over five to 10 years, Ellison said. By factoring in long-term financing options with low monthly payments, it presents the “net investment” of upgrading to a high-efficiency system.

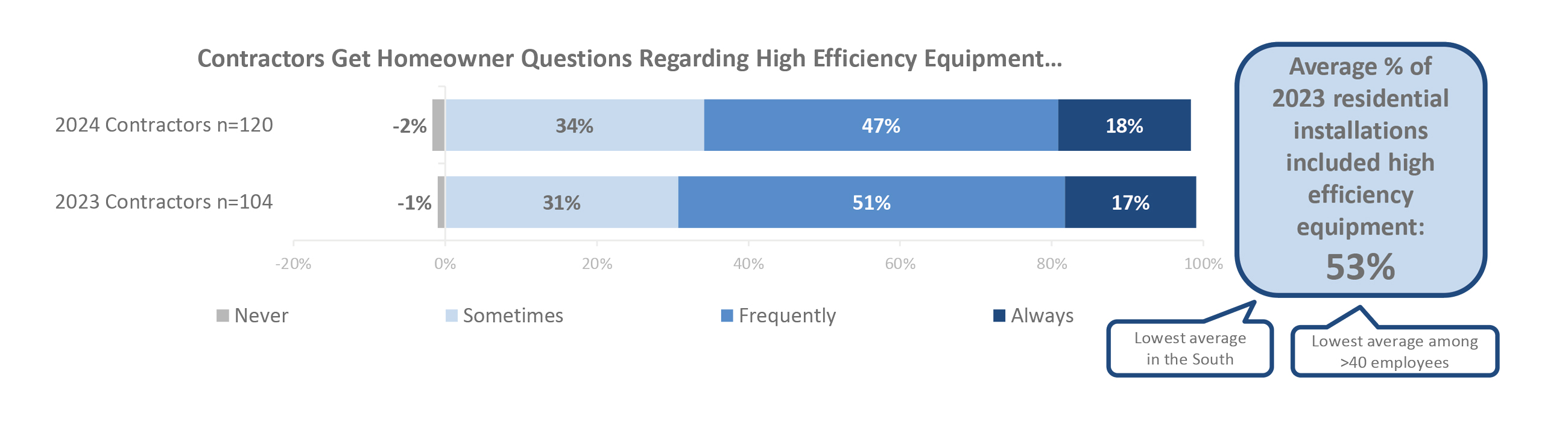

On the contractor side of things, nearly all of those surveyed indicated that they at least sometimes get questions from homeowners regarding high-efficiency equipment, with the type of equipment installed on an average of 53% of jobs last year.

Click graphic to enlarge

COMMON THEME: Virtually all contractors report getting questions on high-efficiency equipment. (Courtesy of myCLEARopinion)

Per the survey, 18% of contractors reported ‘always’ getting questions about high-efficiency equipment, while 47% said it happens frequently, and 34% said it occurs occasionally.

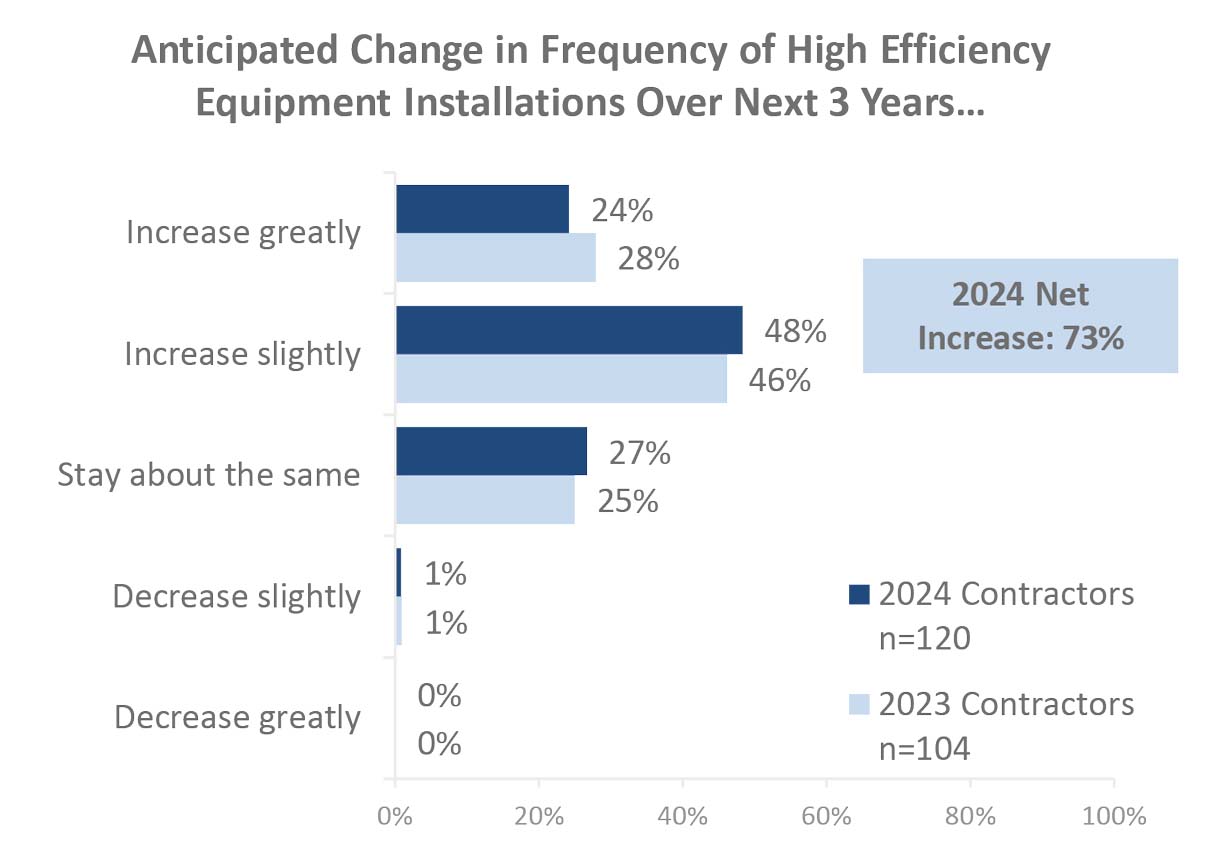

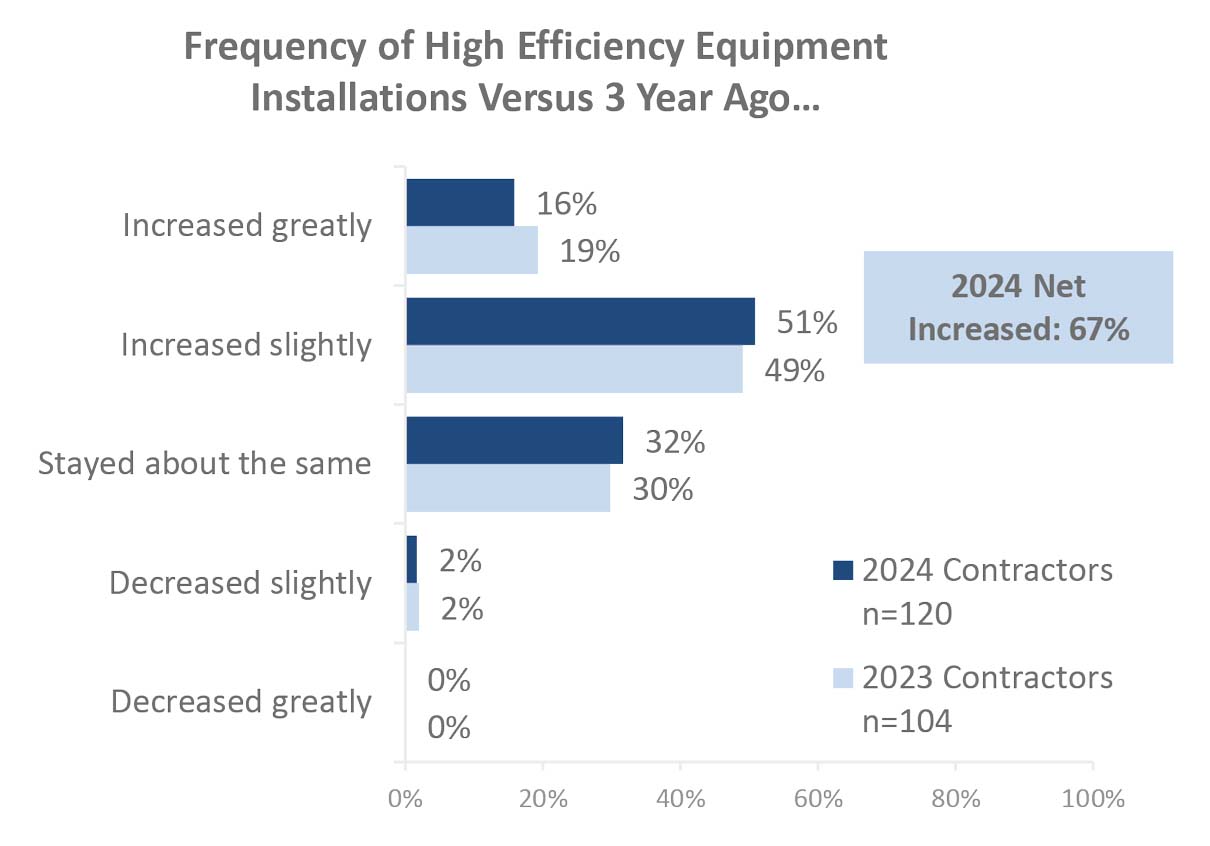

“Contractors indicate the frequency of installation has increased over the past three years, and most expect the frequency of installation to continue to increase over the next three years,” the study states.

Click graphic to enlarge

BRIGHT FUTURE: Contractors are anticipating installation of high-efficiency equipment to continue to increase over the next three years. (Courtesy of myCLEARopinion)

Rames also noted that a recent Midea survey showed nearly identical results, in both homeowner opinions and what contractors are seeing on the ground.

“This trend aligns with regulatory pushes for electrification and decarbonization, emphasizing the importance of heat pump technology as a key solution for both homeowners and contractors,” Rames said. “Contractors should embrace this opportunity by staying ahead of product trends and ensuring their teams are well-trained to handle advanced systems. Collaboration between manufacturers, distributors, and contractors will be essential to meeting this increasing demand.”

For contractors, this means staying ahead of the shift and embracing high-efficiency equipment is a solid business model, but equipment is only part of the equation to ensure success.

Click graphic to enlarge

UPWARD TREND: The frequency of high-efficiency equipment installation is on the rise. (Courtesy of myCLEARopinion)

Tax Credits

To help offset the cost of high-efficiency equipment, many contractors and homeowners turn to the incentives afforded by tax credits, but, while appealing, there are a lot of moving parts in that realm as of late that both parties need to be aware of.

With a new administration in the White House that holds a drastically different energy policy view than its predecessor, things can change quickly, so it’s more important now than ever for contractors to stay up-to-date on the latest developments.

Rames said contractors should regularly consult trusted sources, such as government websites, industry associations, and manufacturer resources.

“Most Midea products, for instance, are aligned with program thresholds in the Inflation Reduction Act (IRA) and regional incentives, which contractors can use to guide their customers,” Rames said. “Additionally, offering customers documentation or links to online tools that estimate potential savings can help build trust and transparency in the process.”

As a Lennox Premiere dealer, Ellison said his company has access to the Lennox Pros portal, which provides the most up-to-date information on federal tax incentives that consumers can utilize.

Hoffmaster suggested contractors also add Rewiring America’s Savings Calculator to their bookmarks. Available in both English and Spanish, this tool offers an easy first step for those exploring incentives. It provides a quick estimate of how much financial support they qualify for under the Inflation Reduction Act to upgrade to energy-efficient electric systems.

“As of January 2025, Rewiring America has also included state, local, and utility incentives for users in 15 states and Washington, DC. (AZ, CT, CO, GA, IL, ME, MI, NV, NY, OR, PA, RI, VA, VT, and WI),” Hoffmaster added. “For more information on how customers can qualify for federal tax credits and rebates, you can check out homes.rewiringamerica.org, or the IRS website. It’s also a good idea to check the websites of your state energy office or local utility for more information about the savings programs they offer.”

Meeting Demand

While the state of tax credits may fluctuate, one factor remains constant: Homeowners are drawn to high-efficiency equipment, in part, for the promise of lower energy bills. But meeting increased demand can present both challenges and opportunities for contractors.

According to Hoffmaster, meeting demand comes down to two key factors: equipment availability and a skilled workforce. Both can pose challenges for contractors.

The transition from R-410A to A2L refrigerants has added complexity to equipment availability, and introduced another layer of difficulty.

“To address this, I have personally witnessed multiple contractors who have started to diversify their brand offerings and begin using more than one brand,” Hoffmaster said. “While OEMs’ transition to new A2L lines led to some constraints in 2024, one of the good things that came out of this period was increased communication. Contractors and Distribution had to communicate and work together in a much more frequent and intimate way to be able to meet the demands of this past year and going forward. Doing so can be done by increasing communication and diversification; getting ahead of the need by communicating with distribution, and broadening the equipment brands carried if necessary.”

The skilled labor element is more difficult to address, but Hoffmaster said he’s seen two approaches that promise to be effective.

“The first is to expand training pipelines for the building trades — including expanding placements in registered apprenticeship programs, and taking a contractor-driven approach where contractors search out enthusiastic individuals to teach them the trade. I have long said that folks should quit waiting for skilled folks to appear at their door and, instead, find young men and women who want to learn and ‘build your own technicians.’ I helped develop a training program for one such contractor who decided to do just that,” Hoffmaster said. “The second approach is software for both training as well as commissioning and diagnosis. Many of the popular tool brands used today offer some online training as well as software (usually mobile-based), along with Bluetooth capability that aids in diagnosis, as well as third-party software such as MeasureQuick that ensures (if followed) that proper commissioning is performed and includes the most robust diagnostic functions that I have seen in any platform.”

Rames suggests that contractors invest in training and certifications for installing and maintaining high-efficiency systems, such as heat pumps, and that’s where partnering with a manufacturer, like Midea, can help by way of providing access to comprehensive resources, including educational materials, detailed installation guides and on-site training programs offered training facilities. At Midea, they offer training at its flagship showrooms in Queens, New York, and Orlando, Florida.

“Maintaining an inventory of popular models, like Midea’s Evox G3 Heat Pump, and building strong supplier relationships can further ensure contractors are prepared to meet increasing demand while minimizing delays,” Rames said. “By leveraging manufacturer partnerships and staying updated on advanced technology, contractors can deliver superior service and capitalize on the growing interest in energy-efficient solutions.”

Closing the Sale

Homeowners value clear, concise information that connects product features to everyday benefits, so Rames said contractors should focus on explaining how high-efficiency systems reduce energy bills, enhance comfort, and align with environmental goals when working toward sealing the deal with homeowners.

Rames recommends using in-home consultations, product demonstrations, and customized brochures (digital or printed) to better engage homeowners. He also suggests leveraging manufacturer resources, like videos and case studies, to simplify complex information and build trust.

Ellison advocates for digital presentations and cost estimations, as they allow for quick updates and adaptability in the ever-evolving HVAC market.

Hoffmaster also suggested utilizing technology to seal the deal, as many modern load calculation tools not only generate sales proposals and energy cost estimates but also provide intuitive charts and graphs that make complex concepts easier for homeowners to understand.

“Folks often learn and grasp the information much more easily and quickly by seeing it as well,” Hoffmaster said. “It’s also very important that the salesperson, whether it’s a technician or a comfort advisor, should understand how their specific equipment operates and be able to illustrate its functions to the homeowner in a way they can understand.”

After-the-Sale Challenges

While most of the installation process is the same, Hoffmaster noted the main differences he’s observed are that new high-efficiency equipment is in many cases much larger, so greater attention needs to be paid to proper evacuation practices, and that it takes more time to set up correctly.

“That makes it all the more important to properly address size in the initial home survey,” Hoffmaster said. “Because many OEMs use proprietary communication systems in their high-efficiency equipment, it’s important to take the time upfront to properly set up all the screens, whether on the thermostat or the equipment boards. This will ensure that multiple callbacks are avoided.”

Rames added that manufacturers like Midea can support contractors by offering robust training programs, simplified installation designs (such as Midea’s modular “Block N Lock” AHU), and marketing materials that debunk myths about upfront costs.

“Common challenges include adapting to new installation techniques, managing higher upfront cost, and addressing customer misconceptions about high-efficiency equipment,” Rames said. “The broader industry can support through advocacy for rebate programs, better financing options, and more accessible certification pathways.”

As high-efficiency adoption continues to trend upward, as contractors themselves are anticipating, it’s important to stay ahead of the game by leveraging manufacturer resources, having technicians constantly working to refine installation procedures, and ensuring that homeowners are satisfied with the investment they’ve made.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link