Key Takeaways

- Suction line accumulators protect compressors from liquid refrigerant damage and oil slugging

- Heat pumps, systems with receivers, hot gas defrost, and condenser flooding applications commonly require accumulators

- The internal “U-tube” design separates vapor from liquid while maintaining controlled oil return

- Accumulators must be installed directionally – inlet and outlet connections matter

- A small oil return orifice (typically 0.055″) ensures proper lubrication without liquid damage

Refrigerant Accumulators for Suction Lines are an Accessory Component with a simple job. Their job is to Accumulate any Liquid Refrigerant that may return in the Suction Line. This prevents Liquid Refrigerant from entering the Compressor, which prevents damage to or failure of the Compressor (above image from Danfoss).

Note: As a "secondary" purpose, Accumulators also prevent Oil Slugging from occurring. More on this later.

Which Systems Need Accumulators

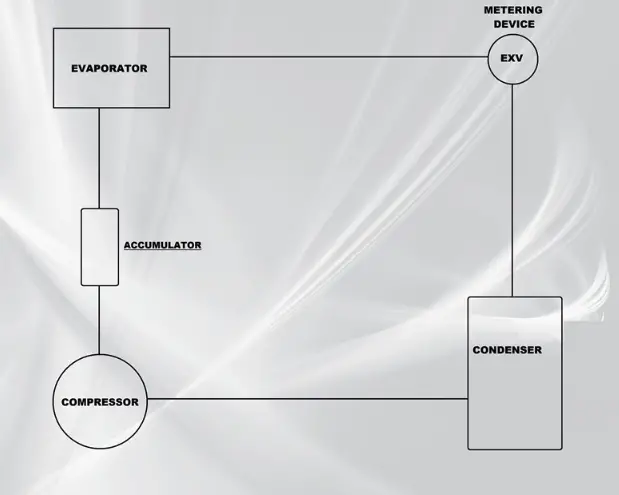

Systems that have the potential for Liquid Refrigerant to exist in different locations within the system in varying operating conditions/modes may require an Accumulator. See the image below for the Accumulator’s location in a Refrigeration/AC System: near the Compressor inlet in the Suction Line.

Systems requiring an Accumulator may include Heat Pumps, systems with Receivers, systems with Hot Gas Defrost, and systems which utilize Condenser Flooding for Head Pressure Control of a Remote Condenser (varying Outdoor Ambient Temperature). For more information on heat pump components and operation, check out our comprehensive guide on bi-flow TXVs in heat pumps.

Note: Training Units used in a student learning application also benefit from Accumulators: this allows students to fully open the Metering Device, as the Compressor is protected from liquid by the Accumulator.

Systems that are Critically Charged and that have very consistent/repeated operating conditions would not require Accumulators, as these systems are manufactured/tested so that liquid returning to the Suction Line is not a concern.

Instagram Video: Dual Accumulator Heat Pump System

Protecting Your Compressor from Liquid Refrigerant

A scenario in which Liquid Refrigerant may enter the Compressor Suction Line is as follows. A Freezer’s Direct Expansion Evaporator has its Evaporator Fan Motor fail, as the call for cooling continues. The Metering Device continues to feed Liquid Refrigerant, while the rate of Evaporation reduces within the Evaporator due to insufficient heat transfer without the aid of the fan. This ultimately leads to a lack of Refrigerant Evaporation in the Evaporator, which allows liquid refrigerant to enter the Suction line. With no additional protection, this will lead to Liquid Refrigerant Entering the Compressor, causing damage or Compressor failure. For more on troubleshooting freezing issues, see our article on comprehensive refrigerant leak detection procedures.

This product listing from Refrigerative Supply for a Copeland Accumulator shows a cutaway in its Installation Manual. I have marked it up in colour, showing a sketch of what I call the “U-Tube” internally, along with the Refrigerant’s flow path.

Note: Accumulators need to be installed considering their Inlet and Outlet, as they are Directional Components.

The refrigerant entering the Accumulator Inlet (whether vapour or liquid state) is free to flow downward within the shell. Following the green arrow path, the refrigerant will travel downward to reach the bottom of the shell. At this point, liquid refrigerant is collected in the bottom of the shell, and vapour state refrigerant is allowed to travel upwards toward the top of the shell.

Refrigerant vapour only is then sucked into the “U-Tube” Inlet. This tube is generally a U-Shape, and it pulls only vapour from the top of the shell and returns it to the Compressor. This arrangement ensures that any possible liquid from the Evaporator is collected at the bottom of the shell, and vapour only is allowed to return to the Compressor.

YouTube Video: Cutting Open a Suction Line Accumulator

Take Control of Your HVAC Business Growth

Managing complex refrigeration systems requires expertise, just like growing your HVAC business requires the right tools. Property.com’s ‘Know Before You Go‘ feature provides instant property intelligence that helps you prepare for service calls involving refrigeration systems. With detailed property histories, equipment locations, and previous service records, you can arrive ready to tackle accumulator issues, compressor problems, or any refrigeration challenge. Join the exclusive network of HVAC professionals who close more deals and deliver superior service. Learn how Property.com helps HVAC pros build stronger customer relationships at mccreadie.property.com.

Protecting Your Compressor from Oil Slugs

Oil Slugging occurs when a large volume of oil is rapidly returned to the Compressor. This will cause failure of the Compressor in a similar way as the return of Liquid Refrigerant would: the Compressor can compress Vapour, not Liquid. Understanding oil return is crucial – for more details, check out our deep dive on oil loss in refrigeration screw compressors.

A scenario where Oil Slugging may occur is as follows. A freezer system’s Evaporator coil is experiencing low Refrigerant Velocity during Unloaded Operation: only 1 of 3 Parallel Compressors is running. This Evaporator coil then enters Hot Gas Defrost: Hot Discharge Gas is injected into the Evaporator coil to remove frost. As this occurs, there is a large Refrigerant Velocity increase, and the vapour-state gas is able to Entrain much oil with it that was “hanging out” in the Evaporator under Low Velocity. This sudden return of oil would cause damage/failure to the compressor without means of protection.

How oil is separated from refrigerant vapour within the Accumulator is very similar to the separation of liquid/vapour state refrigerant as described in the previous paragraph. Oil and vapour both travel towards the bottom of the shell, and oil remains at the bottom as vapour continues its journey back to the Compressor.

Podcast Episode: Compressor Oil Return and Protection

Ensuring Compressor Oil Return

Referencing the “Oil Return Orifice” in the above image, it is a small (0.055″) hole drilled in the bottom of the U-Tube. It will suck oil from the bottom of the shell to bring a manageable amount back to the Compressor during operation.

If Liquid Refrigerant is present, this Orifice will draw both Oil and Liquid Refrigerant in. There is, however, time/space for this small amount of Liquid Refrigerant to be Evaporated in the remainder of the U-Tube, so only oil is returned to the Compressor.

Instagram Post: Oil Return Details

Summary

Accumulators are a great Accessory Component in an AC/Refrigeration System that has varied operating conditions/modes. Reviewing how the internal construction of the Accumulator is set up makes clear how it is able to allow vapour-state refrigerant only to return to the Compressor, while Liquid Refrigerant and Oil are Accumulated.

Understanding accumulator function is just one piece of the refrigeration puzzle. For a complete understanding of system operation, explore our article on the refrigeration cycle explained or dive into troubleshooting gas-fired ignition problems for heating season preparation.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link