✕

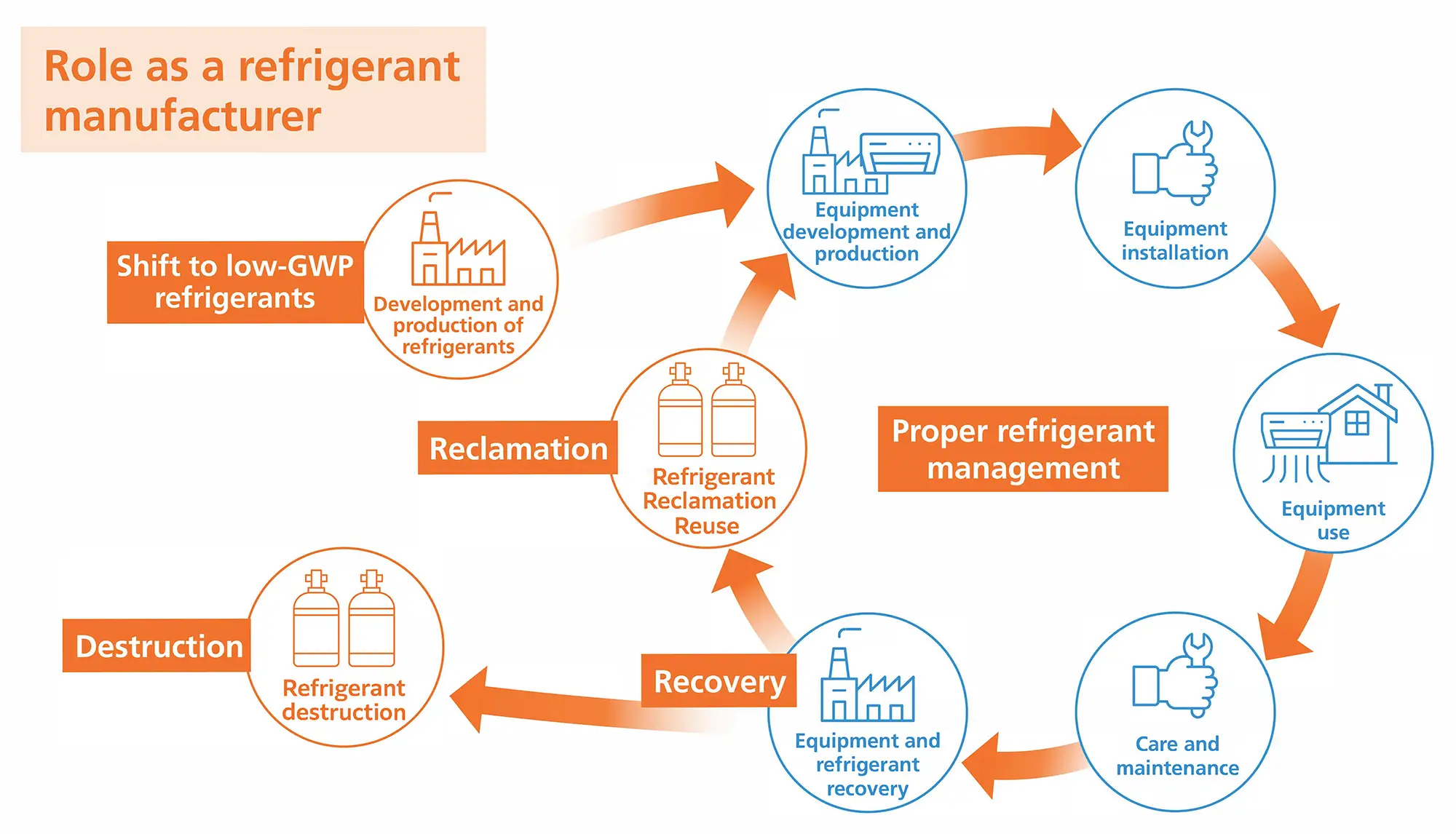

The North American HVAC industry is committed to reducing the environmental impact caused by refrigerants throughout their entire life cycle by strictly managing refrigerants during production and after sales, and recovering, reclaiming or destroying refrigerants after use.

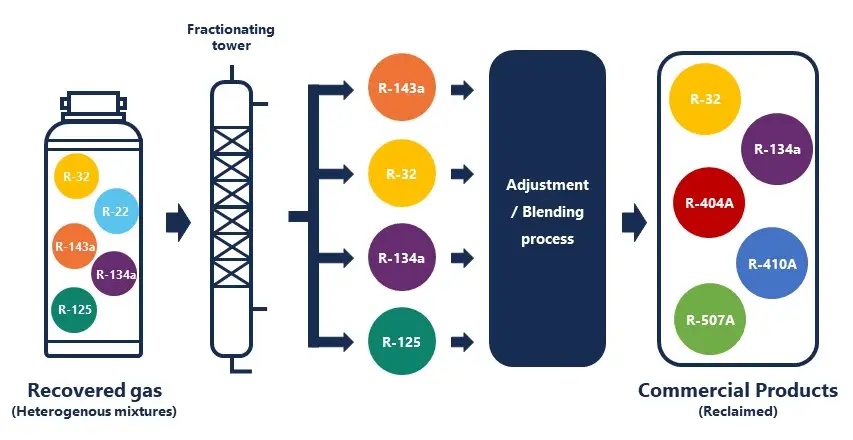

Refrigerant reclamation is defined as the processing, or you might say “cleaning,” of used refrigerant gases so that they can meet specifications for re-use. Reclamation services were designed with the goal of reducing the environmental impact of refrigerants, allowing the re-use of existing refrigerants, thereby avoiding the need to manufacture new virgin refrigerants.

(Courtesy of Daikin, click to enlarge.)

To support sustainable advantages, an evaluation and comparison of the environmental impact of the destruction treatment1 and reclamation treatment2 of recovered refrigerants was completed where 3 indicators, which comprehensively evaluate environmental impacts for not only global warming but also for various areas including health and biodiversity, were used:

- Greenhouse gas (GHG) emissions

- Energy consumption

- LIME3

Compared to destruction treatment, the environmental impact of reclamation treatment for the refrigerant R-410A yielded values that were about 1/7 of GHG emissions, 1/25 of energy consumption, and 1/20 of LIME. Irrespective of refrigerant type, which included R-410A, R-32, R-134a, and R-22, the values in the reclamation process were lower than those of the destruction process for all indicators. Consequently, it is now quantitatively clear that the reclamation process is desirable, in terms of mitigating global warming and resource circulation, compared to destruction of the used refrigerant.

With further awareness of refrigerant recovery and reclamation, informed contactors with properly trained technician understand the importance of the prevention and control of refrigerant leaks, rapid transition to refrigerants with low global warming potential (GWP), and the development of practical refrigerants that are well-balanced in terms of overall aspects of safety, environmental impact, energy efficiency, and cost effectiveness. Through these activities, the HVAC industry contractors and technicians are contributing toward the mitigation of global warming and the realization of a zero-waste society.

1 Destruction treatment refers to the process of decomposing fluorocarbon alternatives, etc., which cause a greenhouse effect when leaked into the atmosphere, into substances that do not have a greenhouse effect.

2 Reclamation treatment refers to the process of removing impurities such as oil, adjusting the components, and converting recovered refrigerant into a reusable refrigerant product.

3 LIME: This is an index that calculates and evaluates the estimated amount of damage by comprehensively evaluating the environmental impact on various areas such as human health and biodiversity including the impact of global warming.

(Courtesy of Daikin, click to enlarge.)

Refrigerant Reclamation Process

Why do we need to do recovery?

The purpose of recovery is to reduce the environmental impact of a refrigerant throughout its lifecycle.

What are the tools required for recovery?

Trained technicians with proper recovery tools such as safety glasses, gloves, refrigerant recovery cylinder, weighing scale, approved refrigerant recovery unit, manifold gauges and proper hoses.

Can the recovered refrigerant be reused?

It is strongly not recommended to reuse recovered refrigerants until they have been through a reclamation cleaning process as there is bound to be the presence of contaminants and impurities. Quality of the refrigerant will be greatly compromised.

How is reclaimed refrigerant different from a new refrigerant?

There is virtually no difference. On the contrary, a reclaimed refrigerant is also an environmentally friendly product.

Can my air-conditioning system use a mixture of reclaimed and new refrigerant?

Yes, it can be a mixture of reclaimed and new refrigerant.

Which types of reclaimed refrigerant are available?

R-410a and R-134a

About Daikin

Daikin Industries, Ltd. (DIL) is a Fortune 1,000 company with more than 98,162 employees worldwide and is the world’s #1 indoor comfort solutions provider. Daikin Comfort Technologies North America, Inc. (DNA) is a subsidiary of DIL, providing Daikin, Goodman, Amana® and Quietflex brand products. DNA and its affiliates manufacture heating and cooling systems for residential, commercial, and industrial use and are sold via independent HVAC contractors. DNA engineering and manufacturing is located at Daikin Texas Technology Park near Houston, TX. For additional information, visit www.northamerica-daikin.com.

Amana® is a registered trademark of Maytag Corporation or its related companies and is used under license. All rights reserved

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link