Key Takeaways

- Error codes indicate sequence failure points, not component failures: That pressure switch code usually means a dirty filter or blocked drain, with actual switch failure being uncommon

- Master the “Big 3” first: Pressure switch, flame sensor, and limit switch errors dominate service calls, with most requiring only cleaning or basic maintenance

- Safety switches are sacred: Never permanently bypass ANY safety device. Rollout switch trips mean immediate shutdown and professional inspection required per OSHA regulations

- Sequence tells the story: Understanding WHERE in the operation sequence the furnace failed is more important than the error code itself

- Test professionally: Use proper tools (manometer for pressure, microamp meter for flame signal) to diagnose root causes instead of throwing parts at problems

You’ve probably learned the hard way: furnace error codes are terrible diagnosticians.

They’ll send you to replace a pressure switch when the real culprit is a kinked drain tube. They’ll flag a flame sensor that just needs 30 seconds with steel wool. Seasoned techs know to treat codes as clues, not conclusions.

These 11 error codes represent the vast majority of furnace service calls. They cross all brands, all ages, all efficiency ratings. Learn to properly diagnose these eleven and you’ll handle the majority of residential furnace failures with confidence.

Reading the Furnace’s Mind: Understanding the Sequence

Furnaces follow a predictable sequence of operations. Each error code represents a failure at a specific point in this sequence. The first diagnostic question isn’t “what’s the code?” but rather “when did it stop working?”

Error codes indicate where the sequence failed, not necessarily what component failed. A pressure switch error often means a dirty filter. A flame sensor code could indicate grounding issues. Understanding this distinction transforms you from a parts replacer to a true diagnostician.

Part 1: Air Flow & Safety Systems

Pressure Switch Errors (Codes 31-33 on Carrier/Bryant, 2-3 flashes on Goodman)

Despite being the most common furnace error, actual pressure switch failure remains uncommon. Most stem from venting restrictions or drainage issues.

The inducer motor creates negative pressure that proves proper venting. The pressure switch simply confirms this vacuum exists, typically measuring -0.7″ to -1.0″ water column.

Common causes by frequency:

- Blocked venting – Bird nests, snow, or debris in exhaust pipe

- Blocked condensate drains – Especially in 90%+ efficiency units

- Spider webs in pressure tubes – More common than expected

- Undersized venting – Installation issue

- Failed inducer motor – Motor not creating sufficient negative pressure

- Actual switch failure – Least common cause

Professional testing methods: Always use a manometer for precise pressure readings. Never use the “suck test” as it can damage switch diaphragms and affect calibration.

Field solutions that work:

- Clear pressure tubes with compressed air (maximum 30 PSI per OSHA 29 CFR 1910.242)

- Use a shop vac at the exterior drain while adding water at the trap

- Check inducer motor amperage (typically 1.4-6.0 amps depending on motor size)

- Verify proper venting is clear and unobstructed

- Check for proper pitch on exhaust venting

High Limit & Rollout Switches

Temperature and flame position switches protect against different hazards. High limit switches protect against overheating (commonly set at 180°F but ranging from 160°F to 300°F depending on application), while rollout switches detect flames escaping the combustion chamber. Never confuse these two, as rollout trips indicate immediate danger.

High Limit Switch Trips (Code 13 on Carrier, 4 flashes most brands)

These switches prevent heat exchanger damage, and repeated trips signal serious safety concerns:

- Most commonly caused by restricted airflow – Dirty filters, blocked vents, undersized ducts

- Often from blower motor issues – Failed capacitors or worn motors

- Sometimes actual limit switch failure – Though relatively rare

- Other causes – High MERV filters, closed registers

Repeated limit trips can crack heat exchangers, creating lethal carbon monoxide risks. Cracked heat exchangers require immediate replacement with no exceptions.

🎙️ Listen to our podcast episode on troubleshooting a faulty high limit switch and spark ignitor for additional diagnostic techniques and field experiences.

Rollout Switch Trips (5 flashes typical) = ⚠️ IMMEDIATE DANGER

Stop everything. Rollout switches detect flames outside the combustion chamber. This indicates:

- Cracked heat exchanger (most dangerous)

- Blocked venting

- Failed inducer motor

- Insufficient combustion air

Required action: Shut down immediately. Professional inspection mandatory. Never reset without determining cause.

Condensate Systems (90%+ Units)

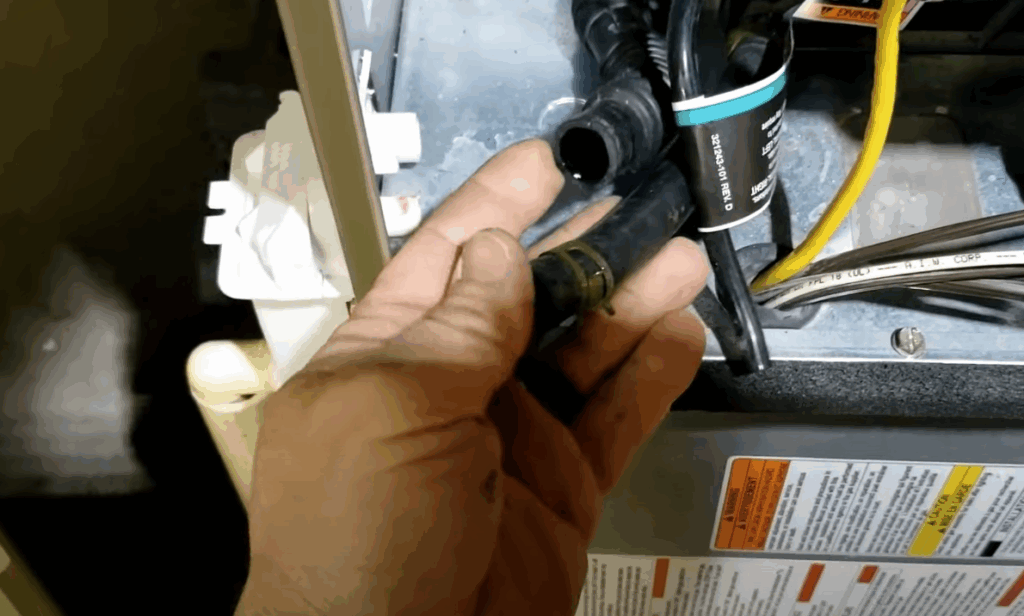

Float switches and pressure switch confusion often occurs in high-efficiency furnaces when blocked condensate backs up into the inducer housing.

Seasonal patterns:

- Winter: Frozen drain lines cause most condensate errors

- Summer: Bacterial growth and debris block drains when humidity is high

- Year-round: Improper trap design creates chronic issues

Emergency drain clearing techniques:

- Connect wet vac to exterior terminus

- Add hot water at indoor trap (for frozen lines)

- Use condensate pan treatment tablets for bacterial growth prevention

- Install overflow switches as backup protection

- Never permanently bypass float switches (water damage liability)

Part 2: Ignition & Flame Proving

Flame Sensor Issues (Code 34 on Carrier, 7-8 flashes on most brands)

The flame conducts electricity, converting AC to DC. The control board measures this tiny current (2-7 microamps) to prove flame presence.

Cleaning requirements: Use fine steel wool (#0000) exclusively. Never use sandpaper or emery cloth, which leave insulating residue that accelerates fouling.

Failure patterns:

- Most just need cleaning – Carbon buildup insulates the sensor

- Some have positioning issues – Must be in flame envelope

- Few have grounding problems – Check all connections

- Actual sensor failure rare – Cracked ceramic or broken rod

Professional diagnostic readings:

- 5-7 microamps: Excellent

- 3-5 microamps: Acceptable

- 2-3 microamps: Clean immediately

- Below 2 microamps: Troubleshoot thoroughly

⏯️ For a visual demonstration of flame sensor troubleshooting techniques, check out our YouTube video on bench testing flame sensors with a megohmmeter, which shows how to check the ceramic insulator for cracks or weakness that can cause intermittent failures.

Hot Surface Igniter Failures (Code 14 on Carrier, 1 flash many brands)

Common failure causes:

- Thermal shock from rapid heating/cooling

- Oil contamination from handling

- Voltage variations

- Age (3-7 year typical lifespan per manufacturer specifications)

Resistance testing standards:

- Silicon carbide: 40-90 ohms when cold

- Silicon nitride: Varies significantly by manufacturer (1-75 ohms)

- Over 100 ohms = weak but may still glow

- Open circuit = replace immediately

Universal igniters work adequately but OEM parts typically last longer. For maintenance agreements, use OEM. For budget repairs, quality universals suffice.

⏯️ For more on universal parts, watch our video on the Emerson White-Rodgers universal flame sensor, which demonstrates how to properly bend and cut a universal sensor to match your specific application.

Part 3: Control Systems

Control Board Diagnostics

Control boards coordinate all furnace operations. Understanding LED patterns speeds diagnosis:

- Steady on: Board failure

- Rapid flash: Active fault

- Slow flash: Stored fault code

- Pattern flash: Specific error (count carefully)

Common failure points:

- Fuses – Check first, cheapest fix

- Transformers – Verify 24VAC output

- Capacitors – Age-related failure

- Voltage regulators – Power surge damage

- Microprocessors – Moisture or heat damage

Replace boards over 10 years old due to parts availability. Communicating systems usually require replacement rather than repair due to programming requirements.

🎙️ Gary’s podcast episode on universal heating parts with Jim Fultz from Emerson dives deep into the new IFC 50M56X-843 universal furnace board that can replace over 550 different control boards.

Inducer Motor Problems

Inducer failures often masquerade as pressure switch errors since the motor creates the negative pressure.

Bearing noise diagnosis:

- Rattling = worn bearings (3-6 months left)

- Squealing = dry bearings (lubricate if possible)

- Grinding = imminent failure (replace now)

Capacitor testing: Test under load with amp clamp. Low amperage indicates weak capacitor. High amperage suggests shorted winding. No amperage means open winding or failed capacitor.

Some furnaces position motors too close to panels, causing overheating. Creating ventilation with a modified cover plate prevents repeated failures.

Part 4: Gas Train Components

Gas Valve Failures

Internal valve components cannot be serviced safely. Any internal leak creates explosion risk.

Safety protocols for gas work:

- Never attempt valve repair – replacement only

- Test with proper manometer for gas pressure

- Check for 24VAC during heat call

- Use bubble solution for external leaks only

- Gas odor = evacuate immediately

Pressure testing requirements per NFPA 54:

- Natural gas: 3.5″ WC at manifold

- Propane: 10-11″ WC at manifold

- Always verify with manufacturer specs

- Document readings for liability protection

The Business Side: Converting Diagnostics to Dollars

Accurate diagnostics build trust and create value. Explaining why a furnace shows a pressure switch code but actually needs a filter and drain cleaning demonstrates expertise customers appreciate.

Building your diagnostic reputation pays dividends. Property.com’s ‘Know Before You Go’ tool helps you arrive at service calls with complete property insights, including permit history that reveals past furnace replacements and HVAC work. This preparation lets you stock the right parts and demonstrate expertise from the moment you arrive.

Field Safety Protocols

Non-negotiable rules:

- Never permanently bypass safety switches – Temporary diagnostic only per manufacturer requirements

- Document everything – Photos, readings, customer communications

- Gas leaks = immediate evacuation – No exceptions

- Multiple safety trips = thorough investigation – Don’t reset and leave

- Maintain proper licensing and insurance – Protects you and customers

Error Code Reference

Carrier/Bryant/Payne Systems

- Codes 31-33: Pressure switch issues

- Code 13: High limit lockout

- Code 34: Flame sensor problems

- Code 14: Ignition failure

Goodman/Amana Systems

- 2-3 flashes: Pressure switch

- 4 flashes: High limit

- 7-8 flashes: Flame sensor

- 1 flash: No signal/ignition failure

Universal Flash Patterns (Most Brands)

- 2-3 flashes: Pressure-related

- 4 flashes: Temperature limit

- 5 flashes: Safety circuit (varies by brand)

- 7-8 flashes: Flame proving

Key Takeaways for Technicians

Error codes are starting points, not diagnoses. The most common codes (pressure switch, flame sensor, and limit switches) rarely indicate actual component failure. Master the sequence of operations for every furnace you service. Know which safety proves what condition. Test with proper equipment. When multiple codes appear or safety switches trip repeatedly, something serious is wrong. Dig deeper.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link