The price of working HVAC methods on industrial properties is a big a part of their working finances. Whether or not utilizing chillers for residential or industrial consolation, course of cooling, or different industrial purposes, maintaining methods working effectively is a quick solution to pad the underside line. Skipping upkeep impacts the chiller’s efficiency and reduces plant effectivity.

Protecting the evaporator and condenser tubes freed from fouling and tube corrosion is a vital preventative upkeep activity for chillers. A correct water remedy program all the time helps, however bodily cleansing is required. Failing to take care of chiller tubes results in scaling, corrosion, and diminished warmth switch all through the cooling system. As warmth switch effectivity falls, working and upkeep prices go up. Cleansing can ship important vitality financial savings. Moreover, different system elements like compressors and pumps must work tougher when tubes are fouled and soiled, including to working prices and put on and tear to these gadgets. Learn on to learn to select the precise tube cleaner to maximise your chiller cleansing.

The Significance of Upkeep/Chiller Cleansing

A industrial HVAC chiller system usually depends on water as its warmth switch technique. The warmth switch course of removes warmth from the water, transferring it to a different fluid, thereby cooling it. It then pumps cooled water by air handlers within the facility, laptop room, or the manufacturing course of. In that course of warmth is absorbed into the water (inflicting a cooling impact) and despatched again to the chiller, or to a cooling tower, or air-cooled warmth exchanger to dissipate the absorbed warmth. The water is then returned to the chiller for additional cooling.

A chiller system with poor warmth switch can not chill areas to the popular temperature.

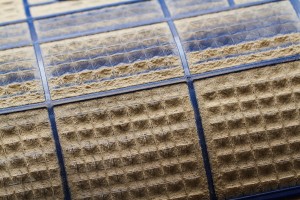

Contaminants in chiller tubes result in poor warmth switch. Laborious water minerals, scaling, algae, and different particles can block condenser and evaporator tubes and impair their functioning.

5 Causes to Carry out Chiller Tube Cleansing

- Keep warmth switch effectivity

- Guarantee energy-efficient operation

- Produce fewer greenhouse gases

- Shield the HVAC system from early failures

- Scale back unplanned downtime

Want Assist Selecting the Proper Tube Cleaner? We’ve Compiled These Suggestions:

Whether or not cleansing chiller tubes for the primary time or it’s time for a course of overview, it’s important to look at the choices accessible. Many methods exist for warmth exchanger and chiller tube cleansing. Listed below are 5 steps to assist select the precise choices for a cleansing utility.

Step 1: Select a cleansing technique. Frequent chiller tube cleansing procedures embody:

- Rod and brush. That is the oldest and least efficient technique. It’s time-consuming and delivers various outcomes.

- Chemical descalers. Circulates an acid-based chiller cleansing chemical by the chiller to take away onerous mineral deposits. This technique works effectively with rotary tube cleaners when heavy scale is current.

- Rotary tube cleaners. A standard and efficient chiller tube cleansing process removes varied deposits.

Step 2: Decide the deposit kind. Earlier than selecting a cleansing technique, decide the deposit kind. Is it:

- Mild to medium buildup, reminiscent of algae, mud or slime?

- Crusty buildup, reminiscent of scale or different mineral deposits?

Goodway provides chiller tube cleansing methods with totally different technical options, reminiscent of built-in water flushes, reversible brush rotation, or variable velocity brush rotation, every designed for particular forms of buildup. Matching the comb bristles to the deposit is necessary.

Step 3: Test chiller tube varieties. Understanding the forms of chiller tubes being cleaned helps technicians choose the precise instruments for the job.

- Smoothbore tubes: These tubes have clean partitions and are generally utilized in chiller warmth exchanger tubes.

- Internally enhanced tubes: These tubes, present in newer chillers and warmth exchangers, have spiral grooves inside to create extra turbulence as water passes by. The design offers extra floor space within the tube, which correlates to higher warmth trade and fewer vitality consumption. Nevertheless, more practical, internally enhanced tubes current distinctive tube cleansing challenges.

Every tube kind requires particular instruments. As an example, a system with variable-speed brush rotation works greatest for internally enhanced tubes.

Step 4: Choose the precise brush. Goodway provides prime quality brushes designed to suit every curve and crevice inside chiller tubes and for various deposit varieties. Brush varieties embody:

- Patriot Duel Diameter Nylon Brushes: Greatest for eradicating smooth deposits in internally enhanced tubes.

- Blue Nylon Brushes: Greatest for eradicating smooth deposits in straight tubes.

- Grit Brushes: Greatest with mild, onerous deposits, reminiscent of mineral buildup in clean bore tubes.

- Brass brushes: Greatest for mild to medium onerous deposits in clean bore tubes.

- Specialised Cleansing Instruments: Obtainable to unravel different tube cleansing challenges, even fully clogged tubes.

Step 5: Select the precise cleaner. Select between AWT-100X Air Powered Tube Cleaner, RAM-4-ID, and RAM-5-ID, and different Goodway cleaners. Every cleaner provides options and advantages to scrub chiller tubes in particular conditions. A Goodway gross sales consultant can match a cleaner to the chiller tube and deposits concerned.

Obtain the whole Chiller Tube Cleaner Shopping for Information.

Utilizing Tube Cleaners to Clear Soiled Chiller Tubes

Choosing the proper tube cleaner comes all the way down to particular variations in energy wants, purposes, and enterprise wants. Regardless of the want, Goodway Applied sciences has them coated.

Goodway just lately up to date its hottest tube cleansing methods.

- AWT-100X Air Powered Tube Cleaner: Probably the most highly effective and versatile chiller tube cleansing answer from Goodway. This tube cleaner delivers portability and intuitive know-how for tubes, pipes, and extra, in moist or dry cleansing circumstances. The chiller tube cleansing machine makes use of air strain, and a cleansing software mounted to the tip of a versatile shaft, to take away robust deposits from boilers, warmth exchangers, and huge pipes.

- RAM-4-ID: The all-new RAM-4-ID is the fifth era of this market-leading tube cleaner. It contains a glossy fashionable design, improved portability, and intuitive controls for easy, one-person operation. Utilizing a versatile shaft with reversible rotation and built-in water flush, the Goodway tube cleansing system delivers highly effective efficiency for quick, efficient cleansing of tubes/pipes ¼-inch to 1-inch (6.4-25.4mm) in diameter in chillers, condensers, evaporators, absorption machines, and warmth exchangers.

- RAM-5-ID: This Velocity Feed Goodway tube cleaner takes high-speed tube cleansing to new ranges and is designed for contractors and facility managers with giant tube bundles. The system options the Goodway unique Velocity Feed gun system that routinely inserts and removes the shaft into tubes to scrub them as much as 4 instances sooner than different condenser tube cleansing methods. Customers can dial within the system’s rotating shaft velocity to fulfill the cleansing wants of particular tube varieties. Including in an built-in water flush creates a speedy technique for cleansing tubes/pipes ¼-inch to 1-inch (6.4-25.4mm) in diameter in chillers, condensers, evaporators, absorption machines, and warmth exchangers.

Subsequent Steps

Protecting evaporator and condenser tubes freed from fouling ensures chillers function as they need to. Goodway provides chiller cleansing instruments, chemical substances, and methods to deal with nearly any chiller cleansing want. Moreover, frequently cleansing cooling towers will cut back tube fouling in case your system has a cooling tower put in. However don’t go it alone. Name a Goodway Industrial knowledgeable to disclose one of the best cleansing strategies, instruments, and chemical substances on your chiller utility.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Supply hyperlink

Add Comment