Energy Savings with VFD Installations for Compressors in Commercial HVAC

In the world of commercial buildings, where energy costs can eat into profits and operational efficiency is key, finding ways to optimize HVAC systems is a smart move. Compressors, powering everything from chillers to refrigeration units, often run the largest motors in these setups—far bigger than those in fans or blowers—and they’re in constant demand across offices, warehouses, and retail spaces. That’s why variable frequency drives, or VFDs, have emerged as a game-changer, delivering substantial energy reductions by tailoring motor speeds to real-time needs. At Air-Tro, Inc., we’ve seen firsthand how these installations are transforming energy management for our commercial clients, cutting bills while boosting system longevity.

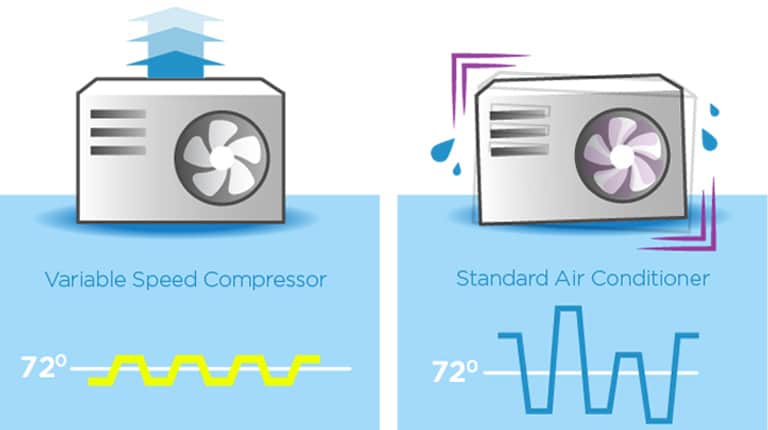

Commercial facilities face unique challenges: fluctuating occupancy, varying weather loads, and the need for round-the-clock reliability. Traditional fixed-speed compressors cycle on and off or run at full throttle, wasting power during lighter demands. VFDs flip this script by dynamically adjusting the motor’s speed, ensuring the compressor only works as hard as necessary. This not only slashes energy use but also aligns with broader sustainability goals, making it easier to qualify for incentives and rebates that reward efficient operations.

What Are Variable Frequency Drives, and How Do They Work with Compressors?

Variable frequency drives are electronic controllers that regulate the speed of electric motors by altering the frequency and voltage of the power supplied to them. In HVAC contexts, they consist of a rectifier to convert AC to DC, a filter for smoothing, and an inverter to recreate a variable AC output. For compressors specifically, this means syncing the unit’s capacity with the building’s cooling or heating requirements—slowing down during off-peak hours and ramping up when demand spikes.

The magic lies in the physics: according to affinity laws governing fluid dynamics in HVAC, power consumption scales with the cube of the motor speed. So, dropping to 50% speed doesn’t halve the energy use—it can reduce it by up to 87.5%. This is especially potent for compressors, which handle heavier loads than fans or pumps and are installed more often than specialized equipment like cooling towers. Government-backed research highlights how VFDs in commercial refrigeration can yield up to 2% annual system-wide energy savings when used strategically as trim controls. In larger setups, like those over 10 horsepower, regulations in places like California are even beginning to mandate their use to meet efficiency standards.

Beyond the basics, VFDs soften starts to avoid power surges, extend mechanical life by reducing wear on components, and integrate seamlessly with building automation systems for remote monitoring. For commercial owners, this translates to fewer disruptions, lower maintenance calls, and a quieter, more controlled environment that keeps tenants comfortable without excess costs.

Energy isn’t the only win—VFDs contribute to peak demand management, potentially lowering utility rates tied to high-usage periods. Studies show that in variable-load scenarios common to commercial HVAC, these drives can achieve significant overall savings, sometimes up to 30% over traditional scroll compressor systems when optimized. They’re particularly effective in spaces with inconsistent demands, like hotels or manufacturing plants, where compressors might otherwise overwork during partial loads.

When considering installation, focus on matching the VFD to your motor’s specs, such as horsepower, voltage, and amps, and opt for inverter-duty rated motors to handle the variable speeds. Placement matters too—wall-mounted or cabinet-enclosed units need proper ventilation to dissipate heat, and adding line reactors can help protect against power surges and voltage spikes. While upfront costs exist, the payback period is often swift, fueled by ongoing savings and available incentives that make the investment pencil out for long-term operations.

Of course, no solution is without hurdles. Regular filter checks are needed to prevent overheating, and in some cases, a bypass option adds expense for redundancy. But for most commercial applications, the pros far outweigh these, especially when professional setup ensures everything runs smoothly from day one.

At Air-Tro, Inc., our team specializes in tailoring VFD solutions to commercial needs, drawing on years of experience to maximize your system’s potential. Whether retrofitting an existing compressor or designing a new install, we’re committed to delivering results that show up on your bottom line.

Learn More About Our VFD Options for Commercial Buildings

Frequently Asked Questions

What Are Variable Frequency Drives and Their Role in Commercial HVAC? VFDs are devices that control motor speeds by varying electrical frequency, allowing compressors to match output to demand and save energy in commercial buildings.

How Do VFD Installations Save Energy for Compressors? By reducing motor speed during low loads, they cut power use dramatically—often following a cubic relationship where halving speed reduces consumption by up to 87.5%.

What Benefits Do VFDs Offer Commercial Facilities? They lower energy bills, extend equipment life through soft starts, reduce noise and vibration, and help with peak demand charges, making operations more efficient overall.

Are There Any Drawbacks to Installing VFDs on Compressors? Potential issues include initial costs, the need for regular maintenance like filter cleaning, and addressing electrical harmonics, but these are typically manageable with proper planning.

What Should I Consider During VFD Installation in a Commercial Setting? Match the drive to motor ratings, ensure adequate cooling and enclosure protection, and integrate with controls for optimal performance—professional guidance is key.

Can VFDs Be Retrofitted to Existing Commercial HVAC Systems? Yes, they’re often added to older compressors for upgrades, providing energy savings without a full system overhaul, especially in variable-demand environments.

How Much Can Commercial Businesses Save with VFDs on Compressors? Savings vary, but research indicates up to 30% over conventional systems in some cases, with quick paybacks through reduced energy and maintenance costs.

Boost Your VFD Installations for Compressors

Take control of your commercial energy costs and step into a more efficient future. With VFD installations for compressors from Air-Tro, Inc., you’ll unlock substantial savings, reliable performance, and peace of mind knowing your HVAC is optimized for the long haul. Call us today at (626) 357-3535 to discuss how we can customize a solution for your facility—let’s make your operations smarter and more sustainable.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link