Refrigerant Volume Matters

An often overlooked consideration in a mechanical cooling system is gas volume. Gas volume can describe the cubic footage of space that a gas is taking up per pound of the gas by weight (expressed in ft3/lb).

Consideration of refrigerant gas volume is most important when looking at refrigerant conditions in the suction line. The ‘lighter and fluffier’ (coined by the author) that the gas is, the more of it your compressor must pump to accomplish 1 Ton of Cooling (12,000 BTU/hour).

More specifically, volume is referred to as “Specific Volume.” For example, a Reciprocating Booster Compressor (1st of 2 compression stages) must have physically large cylinders to pump enough of the low temperature/high specific volume gas required to achieve its capacity.

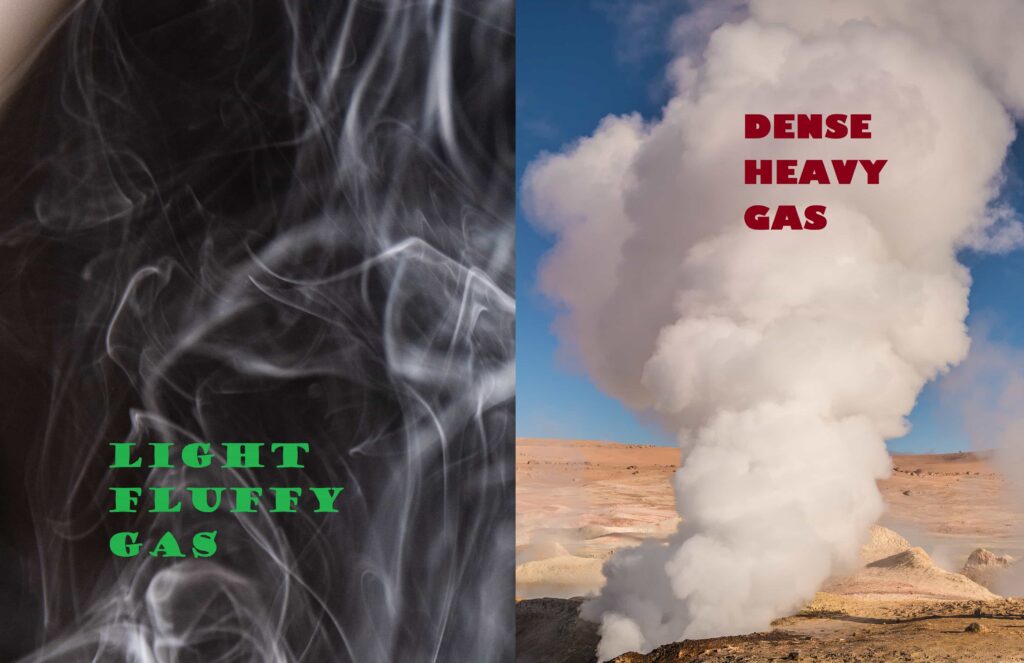

Note that Booster Compressors pull a low SST (Saturated Suction Temperature) gas, perhaps -20°f SST, which has a high Specific Volume (SV). A gas with high Specific Volume is represented on the left side of the image below.

…then there’s Density

The opposite of specific volume is Density. Density (D) can be described as the weight of refrigerant in pounds per cubic foot of space the gas is taking up (expressed in lb/ft3). Air conditioning compressors pull suction from a high-temperature gas around 40°f SST, which is a very dense gas.

Using a Reciprocating Compressor again, its cylinders will be much smaller. This is for two reasons: firstly, it needs to move less total refrigerant (since it is dense) to accomplish e.g. 1 Ton of Cooling. The second reason is if the cylinders were large, the Compressor would easily pull a high motor current as this dense (heavy and sluggish?) gas takes more work to compress.

The right side of the image above represents a gas with high density. Different Compressors exist for different desired suction temperatures. When they’re represented mathematically, density and specific volume are reciprocal (image below).

Pressure Enthalpy Diagram

For any Compressor’s operation, the importance of gas volume can be clearly shown on a Pressure Enthalpy Diagram. The remainder of this article will take for granted that the reader understands Pressure Enthalpy Diagrams and how refrigeration systems are plotted on them.

To learn these details or brush up on them, please visit Sporlan Pressure Enthalpy Diagram. This PDF is a great resource, which I reference regularly during classes on PE (Pressure Enthalpy).

Danfoss Cool Selector 2

The PE Diagrams shown in the remaining images are from the Danfoss Cool Selector 2 application. This free tool can be downloaded or viewed online.

Here is a video that shows (at 1:32) how to access PE Diagrams from Cool Selector. Within the application, they are referred to as “p-h” diagrams, with “h” representing enthalpy. You can also plot Compressors/systems within the app. (shown later in the video), select equipment, perform heat load calculations, and more.

Gas Volume Increases on a Decrease in SST

Picture your customer making a request to change the operating conditions of their cooler. They instead would like to run their cooler as a freezer. Something like this can be done by reducing the SST of the Compressor which pulls suction on the refrigerated space’s evaporator.

If the LPCO (Low Pressure Cut-Out) is the Compressor operating control, this switch could be operated to have the Compressor turn off at a lower pressure corresponding to the new desired SST. To see the ill effects this could cause, we can use the Pressure Enthalpy Diagram. In the image below, an SST of 40°f and an SST of 0°f are both referenced on the 100% Saturated Vapour Line.

Their Specific Volume values (expressed in ft3/lb) are illustrated by the lines extending to the right side of the graph. It can be gleaned from this that a reduction in SST causes an increase in the Specific Volume of the refrigerant.

The characteristics of Saturated Vapour can be remembered by comparing them to freezing water: as the water freezes, it continues to expand. Mechanics and operators need to consider this increased gas specific volume when lowering the Compressor SST.

Negative Effects of Reducing SST Due to Increased SV

- Increased SV: must pump more refrigerant per ton of cooling.

- Increased gas entropy: less efficient compression.

- Reduced hermetic motor cooling: though the gas is ‘colder’, its large volume results in less winding cooling.

- Reduced volumetric efficiency.

- Reduced Compressor capacity

- Reduced COP (Coefficient of Performance).

- If SCT (Saturated Condensing Temperature) is held constant:

- Increased compression ratio.

- Higher discharge gas temperatures.

- Higher oil temperatures.

Gas Volume Increases on an Increase in Suction Superheat

A TXV (Thermostatic Expansion Valve) is a common, adjustable Metering Device that functions on the premise of an evaporator outlet superheat. In a basic system, a single Compressor pulls a short suction line from the evaporator.

If the TXV is adjusted incorrectly, it will constantly allow a higher-than-necessary superheat value to the Compressor during operation. Superheat is required to be added to the refrigerant to ensure the Compressor (a vapor pump) does not see refrigerant in its liquid state.

Any more Superheat returning to the Compressor than required is a system inefficiency. In the below Pressure Enthalpy Diagram, there are two plot points considered at an SST of -20°f for example. The first plot point represents a suction gas which has gained 60°f of Superheat.

The second plot point shows an extreme amount of Superheat added, totaling 180°f of Superheat. What can be noticed is an increase in Superheat returning to the Compressor will also cause an increase in the Specific Volume of the return gas.

Characteristics of a Superheated Vapour can be remembered by comparing it to air: ‘hot’ air rises, as its volume increases. Note that a Saturated and a Superheated Vapour’s Specific Volume react in opposite ways to temperature change.

How Excess Superheat Reduces System Efficiency

- Higher return gas temperatures.

- Higher discharge gas temperatures.

- Higher oil temperatures.

- Factors due to SV increase caused by increased Superheat:

- Less hermetic motor cooling.

- Reduced compressor capacity.

- Reduced volumetric efficiency.

Closing Thoughts

Two different things can put stress on a compressor. Both do this by increasing the return gas-specific volume. These are reducing SST and increasing Superheat.

A Pressure Enthalpy Diagram can be a good way to visualize concepts like this while also applying metrics to the idea in the form of numbers. If you can manage it, save light and fluffy for your desserts.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link

Add Comment