When troubleshooting HVAC systems or designing new installations, engineers should follow these essential steps, regardless of whether they work for consulting firms or mechanical contractors.

The process starts with hiring a testing, adjusting and balancing (TAB) contractor to measure air readings at engineer-designated points. This identifies system deficiencies and begins the problem-solving phase.

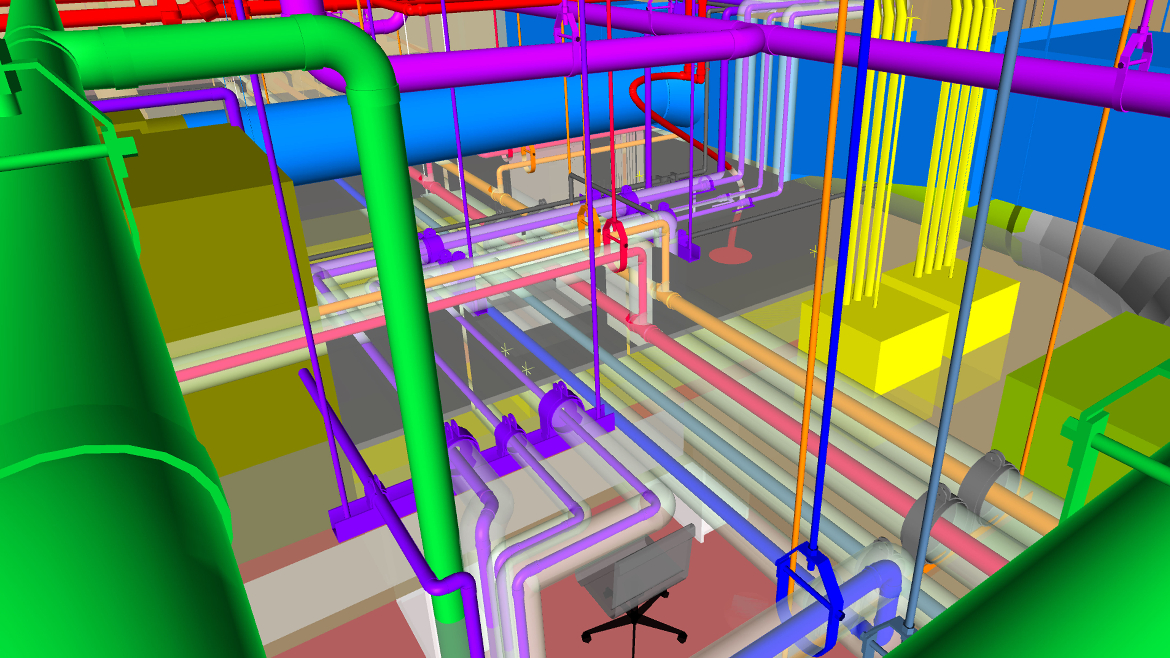

Start with a system flow diagram – the engineer’s roadmap to understanding design intent and developing solutions. Next, add the automatic temperature control sequence to the diagram, including control devices and damper and valve positions (normally open or closed). This method works for both existing system analysis and new design-build projects. The diagram also helps third-party commissioning agents understand the design.

The engineer should then review existing conditions with the building owner’s representative, typically the facility manager, and tour the equipment room. Document any deficiencies, such as disconnected return air damper linkage, in a “corrective action log” for immediate or future repair.

Share the completed documentation with project subconsultants. The flow diagram helps electrical and plumbing engineers verify conditions. For new projects, the diagram assists automatic temperature control and TAB contractors during implementation.

Building owners benefit from the flow diagram and operation sequence, which help facility staff understand the system’s design intent.

For electrical components, the diagram should note:

- Emergency and normal power sources

- Fire and smoke detector integration

- Power disconnects per National Electric Code

- Interlock wiring specifications

For plumbing systems, document:

- Condensate drain points

- Gas requirements

- Pressure relief piping

All three major TAB organizations – National Environmental Balancing Bureau, Testing Adjusting and Balancing Bureau, and American Air Balancing Council – recommend completing system flow diagrams. These should include:

- Cubic feet per minute (CFM) measurements

- Static pressure readings

- Air velocity in feet per minute (FPM)

- Final balancing data

Troubleshooting checklist:

- System flow diagram

- Operation sequence with control specifications

- Piping configuration

- Electrical data

- Plumbing details (when applicable)

- Structural weights (for design-build)

- TAB measurement points

This approach works for both troubleshooting and new installations. The documentation helps commissioning agents create functional performance test narratives and provides building owners with reference materials for future system recommissioning or problem-solving.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Source link