A standard metering machine used on new walk-in cooler/freezers at this time is the digital growth valve (EEV). It permits for a tighter management of a refrigerant’s superheat worth leaving the evaporator and a faster response to modifications within the evaporator’s warmth load. Nevertheless, as with all digital elements, there’s a studying curve related to troubleshooting a few of its widespread failures.

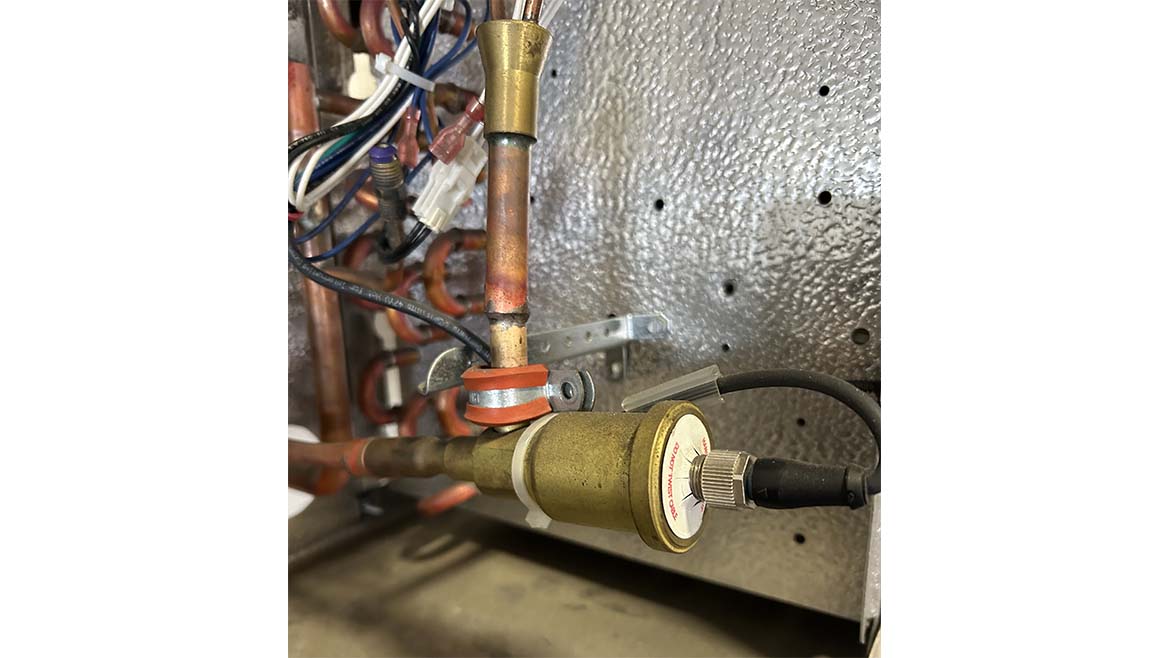

These metering gadgets usually include a number of primary elements: 1) a valve physique with a needle valve meeting used to vary its port opening; 2) a magnetic coil used to reposition the needle valve; 3) a suction strain transducer; 4) a suction line temperature sensor; and 5) a management board to learn a strain transducer and a suction temperature sensor as inputs, then based mostly on its programming, ship a voltage sign to the magnetic coil to both transfer the needle valve into or away from the port.

When troubleshooting these valves, it’s all the time greatest to acquire and comply with the producer’s service literature, because the design and operation could also be barely totally different from one producer to a different.

Typically, step one in troubleshooting these valves is to measure precise suction strain and suction line temperature of the refrigerant leaving the evaporator and calculate its present superheat worth. Then, navigate to a menu on the management board to view these values, which ought to be related. If the suction strain or suction line temperature values usually are not related, then seemingly the problem is with the sensor. Additionally test that the right refrigerant kind has been chosen and the management superheat set level is appropriately set on the board. If these values are flawed, it’s going to additionally trigger the valve to not function appropriately.

If the valve remains to be not working correctly, the subsequent step is to measure the magnetic coil winding’s resistance. Following the producer’s instructions, measure the resistance of every winding and likewise confirm that there is no such thing as a continuity between the windings and floor. If the resistance values usually are not right, then the seemingly challenge is the coil, and it’ll must be changed.

If the resistance of the magnetic coil is okay, attempt to transfer the needle valve meeting with a magnetic software obtained from the producer. Turning the magnetic software clockwise and counterclockwise will help you transfer the needle valve to a extra open or extra closed place. If utilizing this software doesn’t trigger a change within the suction strain and/or temperature, then the valve must be changed.

One other potential challenge with these valves is their failure to fully shut throughout the off-cycle or defrost cycle. These valves are sometimes used to pump down the system when the case reaches its temperature set level or throughout a defrost cycle. These programs won’t have a liquid line solenoid, as a result of the EEV is designed to fully shut throughout the off-cycle and defrost cycle, so it isn’t wanted.

To check this operate, both place the unit right into a defrost cycle or elevate the temperature set level and watch the system pump down. If it doesn’t pump down correctly, the EEV could must be changed. This challenge may be brought on by a faulty compressor. Earlier than condemning the EEV, strive pumping down the system utilizing the king valve on the receiver. If you’ll be able to pump the system down when the king valve is in its entrance seated place, then the EEV is the problem. In case you can’t pump down the system with the king valve entrance seated, the compressor is the seemingly trigger.

Troubleshooting these valves could seem a little bit difficult at first, however as you’re employed with them increasingly, the training curve goes down and the benefit of troubleshooting goes up.

Whether you require installation, repair, or maintenance, our technicians will assist you with top-quality service at any time of the day or night. Take comfort in knowing your indoor air quality is the best it can be with MOE heating & cooling services Ontario's solution for heating, air conditioning, and ventilation that’s cooler than the rest.

Contact us to schedule a visit. Our qualified team of technicians, are always ready to help you and guide you for heating and cooling issues. Weather you want to replace an old furnace or install a brand new air conditioner, we are here to help you. Our main office is at Kitchener but we can service most of Ontario's cities

Supply hyperlink

Add Comment